A kind of d-sub waterproof connector and its making method

The technology of a waterproof connector and a manufacturing method is applied in the directions of contact parts, fixed/insulating contact members, and assembly/disassembly of contact parts, which can solve the problems of accelerated oxidation of metal parts plating, easy generation of burrs, and unstable dimensions. Achieve the effect of improving quality, improving efficiency and reducing assembly defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

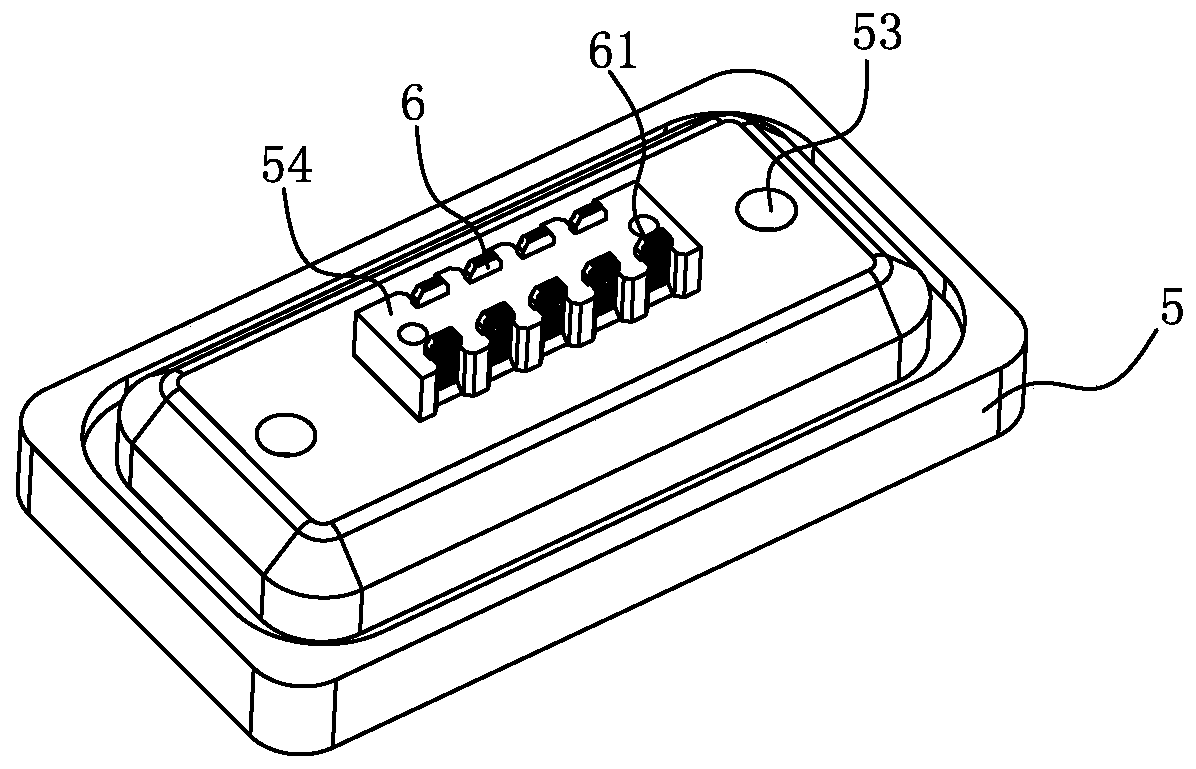

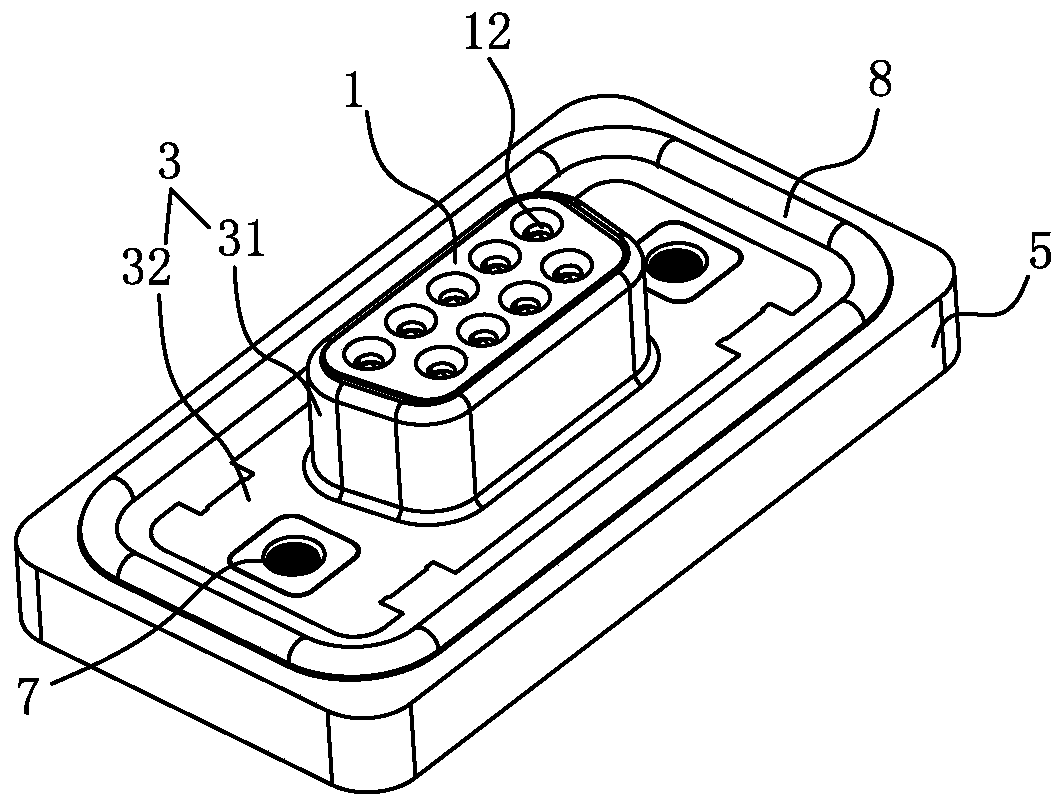

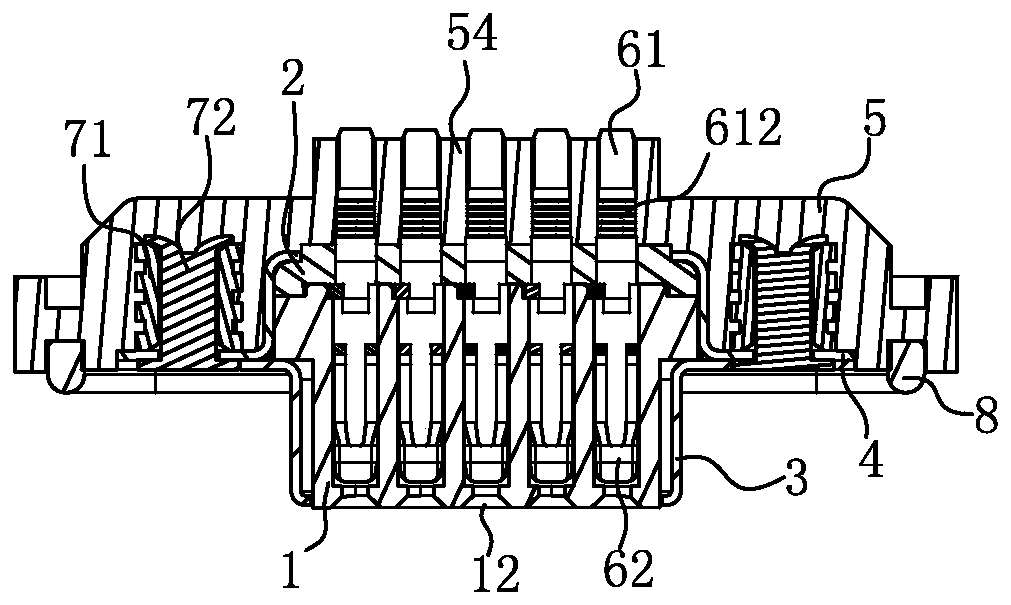

[0050] See Figure 1-3 As shown, a D-SUB waterproof connector has a connector semi-finished product, the connector semi-finished product includes: an insulating base, a terminal group 6 installed on the insulating base, and a front housing 3 installed outside the insulating base and The rear shell 4, the front shell 3 and the rear shell 4 are stably connected by the riveting assembly 7 and the insulating base is limited between the front shell 3 and the rear shell 4, and the end of the semi-finished connector is connected with an insulating The bracket 5 is sealed and connected between the insulating bracket 5 and the semi-finished connector.

[0051] See Figure 5-6 As shown, the insulating base includes: a front insulating base 1 and a rear insulating base 2 installed on the front insulating base 1, and the front insulating base 1 is provided with a jack 11 for terminal group 6 installation, The jack 11 is opened from the rear end of the front insulating base 1 to the fron...

Embodiment 2

[0078] See Figure 8 As shown, a D-SUB waterproof connector has a connector semi-finished product, the connector semi-finished product includes: an insulating base, a terminal group 6A installed on the insulating base, and a front housing 3 installed outside the insulating base and The rear shell 4, the front shell 3 and the rear shell 4 are stably connected by the riveting assembly 7 and the insulating base is limited between the front shell 3 and the rear shell 4, and the end of the semi-finished connector is connected with an insulating The bracket 5 is sealed and connected between the insulating bracket 5 and the semi-finished connector.

[0079] The insulating base includes: a front insulating base 1 and a rear insulating base 2 mounted on the front insulating base 1, the front insulating base 1 is provided with a jack 11 for terminal group 6 installation, and the jack 11 From the rear end of the front insulating base 1 to the front end, a circular through hole 12 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com