Stator and stator assembly method

An assembly method and stator technology, which is applied in the manufacture of stator/rotor bodies, electromechanical devices, electric components, etc., can solve the problems of phase lines crossing each other, and achieve the effects of avoiding short circuits, efficient automatic production, and fast assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the specific implementation of the stator and the stator assembly method of the present invention will be described below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

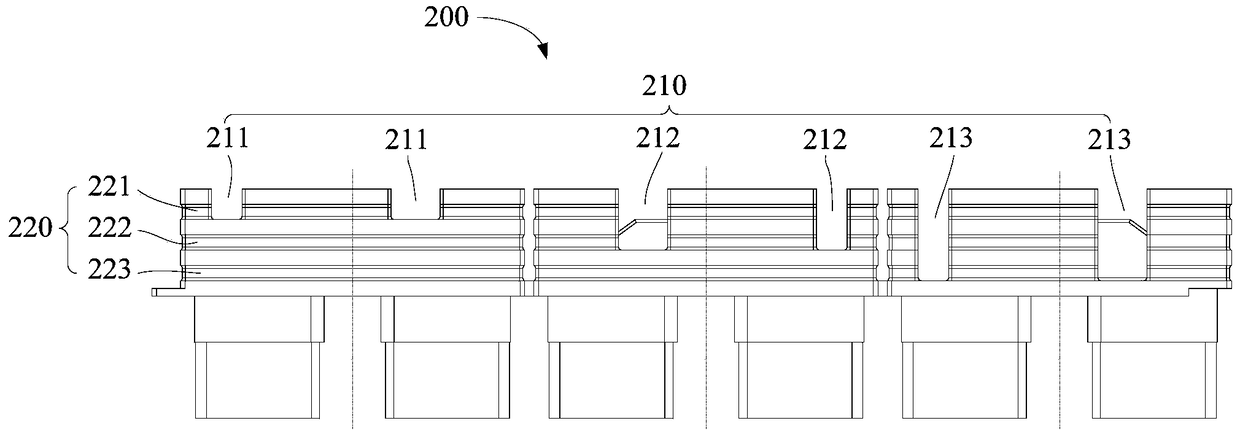

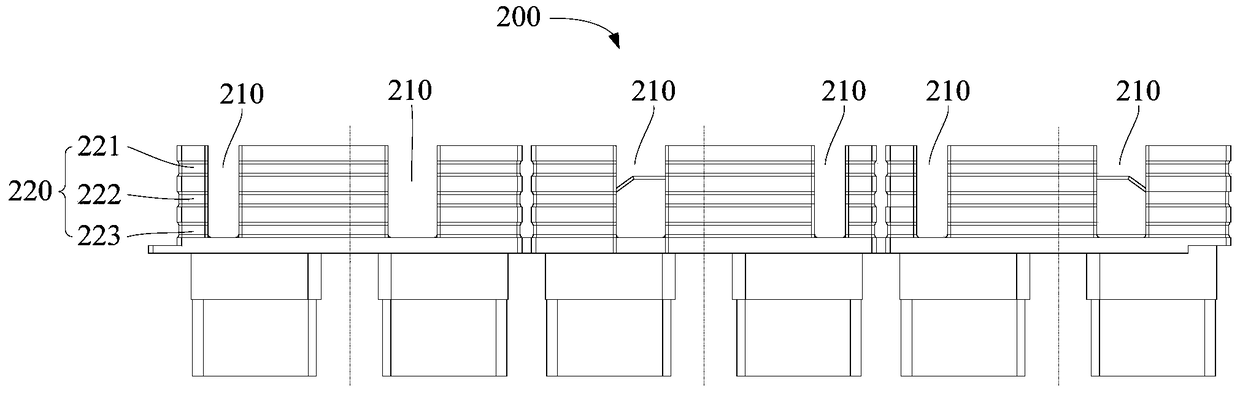

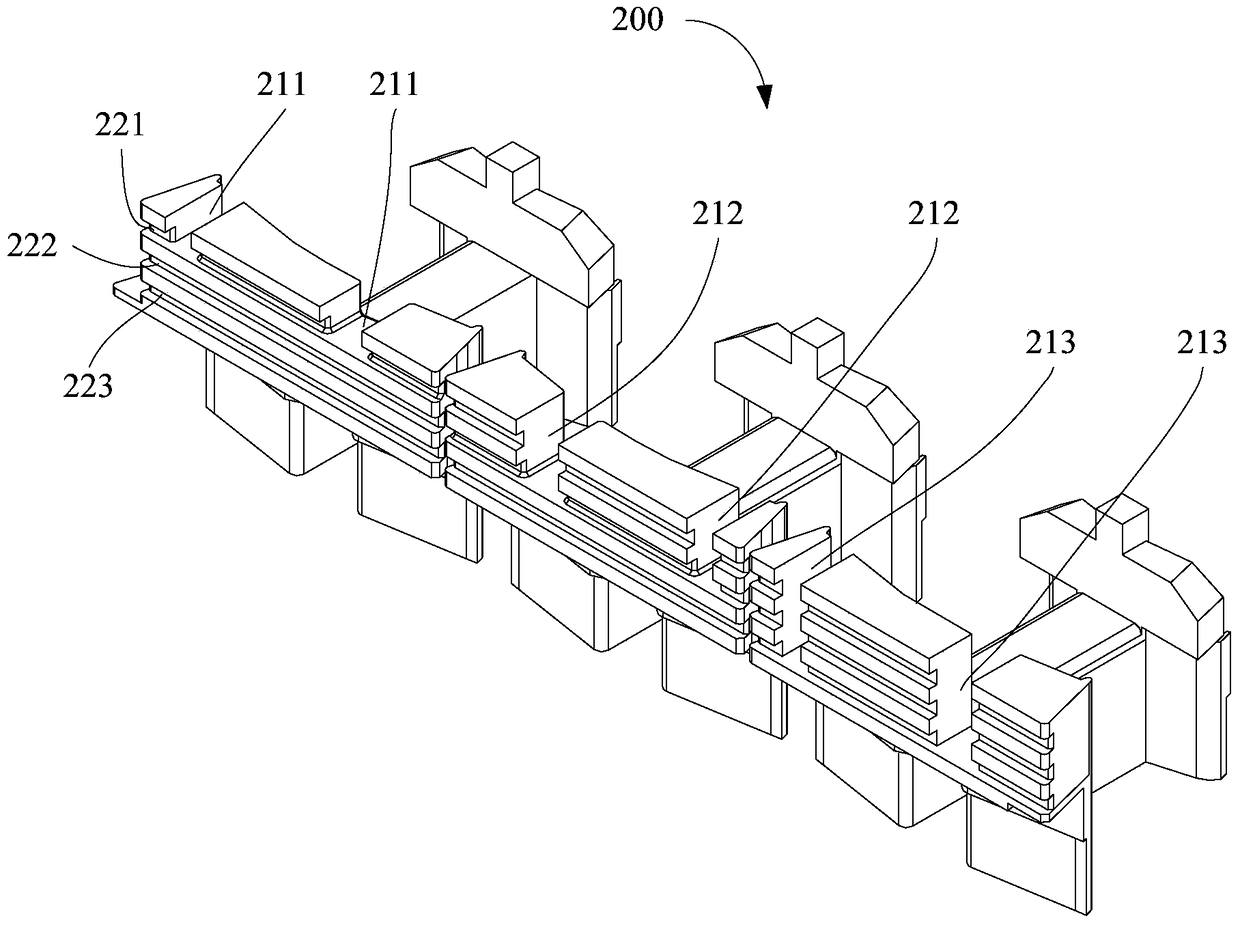

[0050] see Figure 1 to Figure 6 , In one embodiment, the insulating frame of the present invention includes a first insulating frame 200 and a second insulating frame 300 for being installed at both ends of the motor stator core 100 . A portion of the first insulating frame 200 corresponding to each stator tooth 110 of the stator core 100 is provided with at least two wire inlet / outlet ports 210 . The outer side of the first insulating frame 100 is also provided with layered wire passing grooves 220 . The wire slot 220 passes through the wire inlet / outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com