Electrophoresis tank convenient to fix rubber making plate

An electrophoresis tank and gel plate technology, which is applied in the field of electrophoresis tank, can solve the problems such as the movement of the gel plate, the deviation of the electrophoresis strips from the swimming lane, and the confusion of each other, so as to achieve the effect of ensuring linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

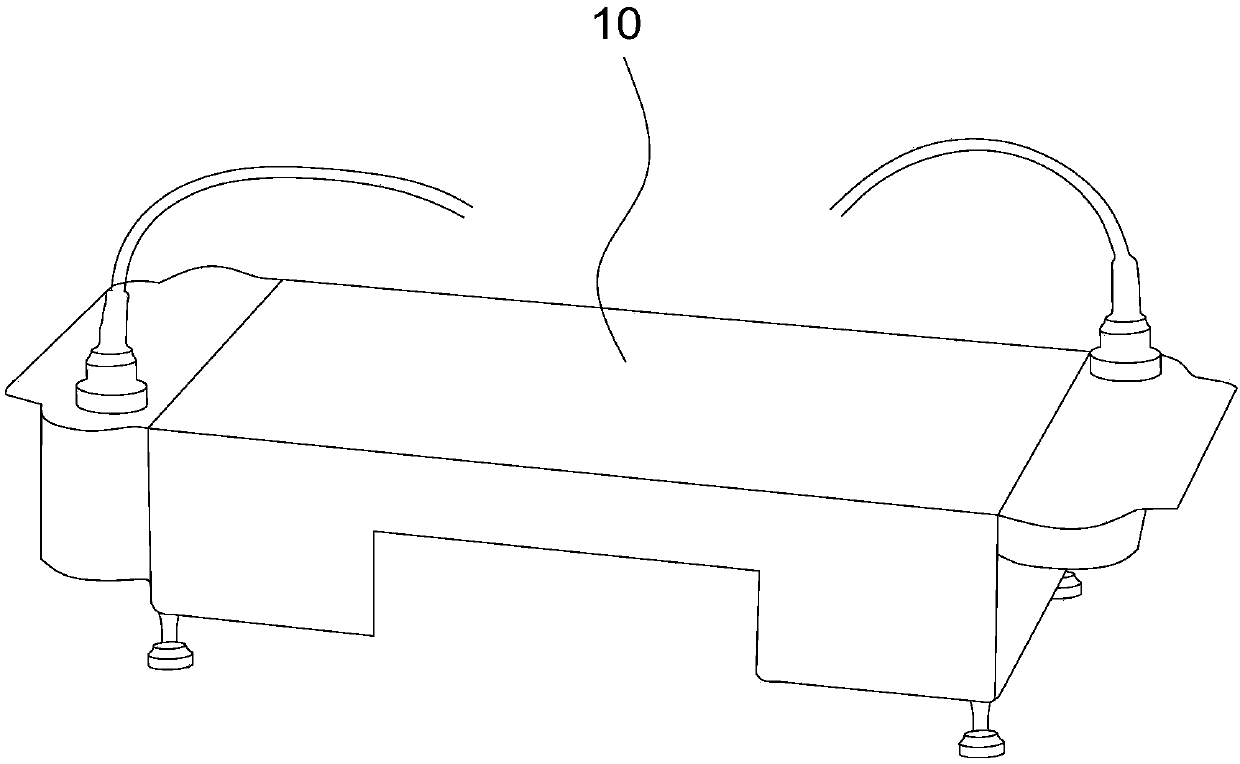

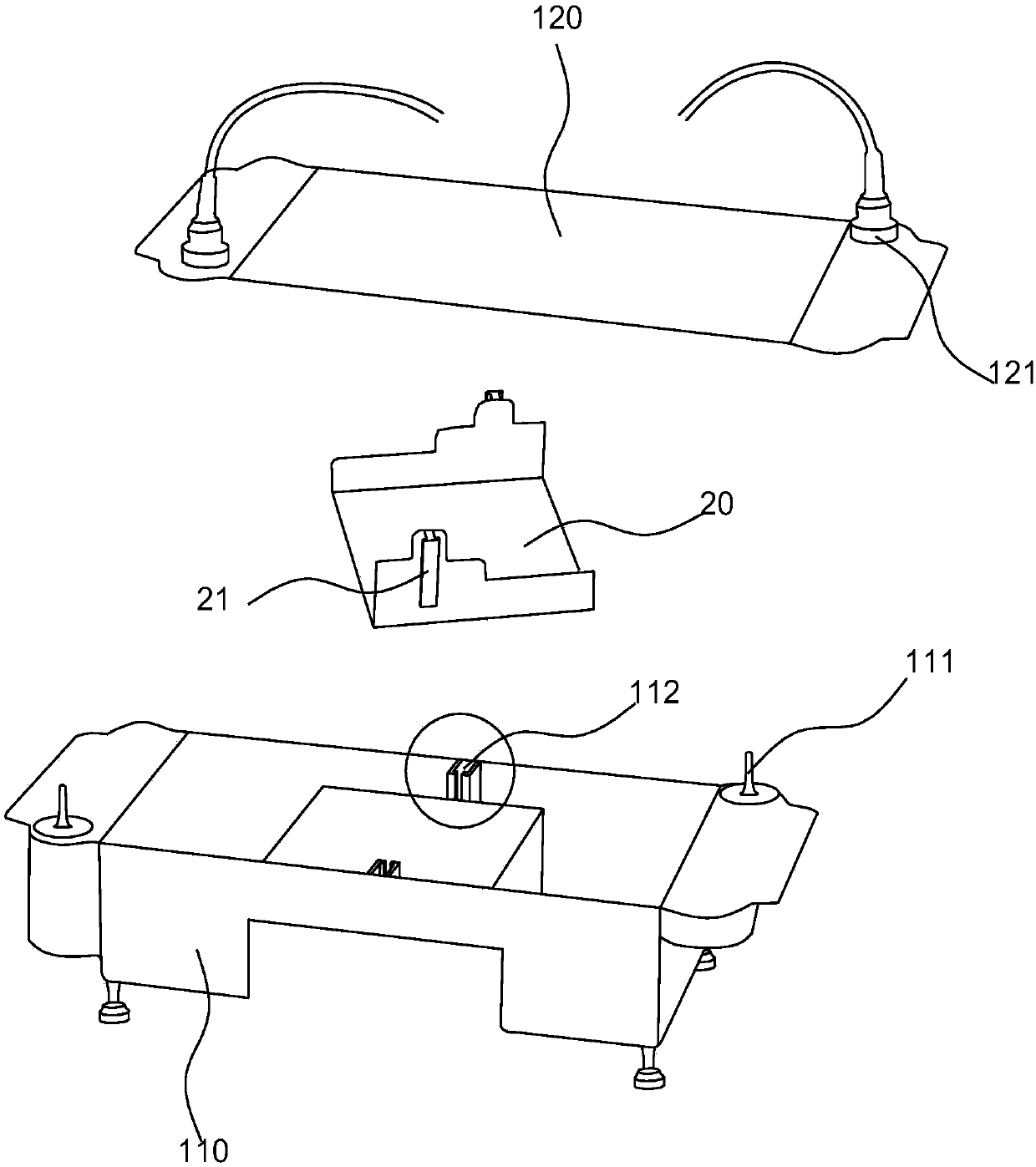

[0029] Such as figure 1 As shown, it is an electrophoresis tank for fixing gel plates according to an embodiment of the present invention. Such as figure 2 shown, for figure 1 The disassembled state diagram of the electrophoresis tank shown.

[0030] Such as Figure 1-3 As shown, the electrophoresis tank that is convenient for fixing the gel plate includes an electrophoresis tank 10 and a gel plate 20. The electrophoresis tank 10 includes a tank body 110 and a cover body 120. Electrodes 111 are arranged at both ends of the tank body 110, and the cover body 120 is provided with corresponding electrodes. There is a conductive ring 121 electrically connected to the power source. When performing electrophoresis, when the cover body 120 can be covered on the tank body 110, the electrodes 111 are connected to the power supply, and an evenly distributed electric field is formed between the electrodes 111 at both ends of the tank body 110, and the charged nucleic acid or protein ...

Embodiment 2

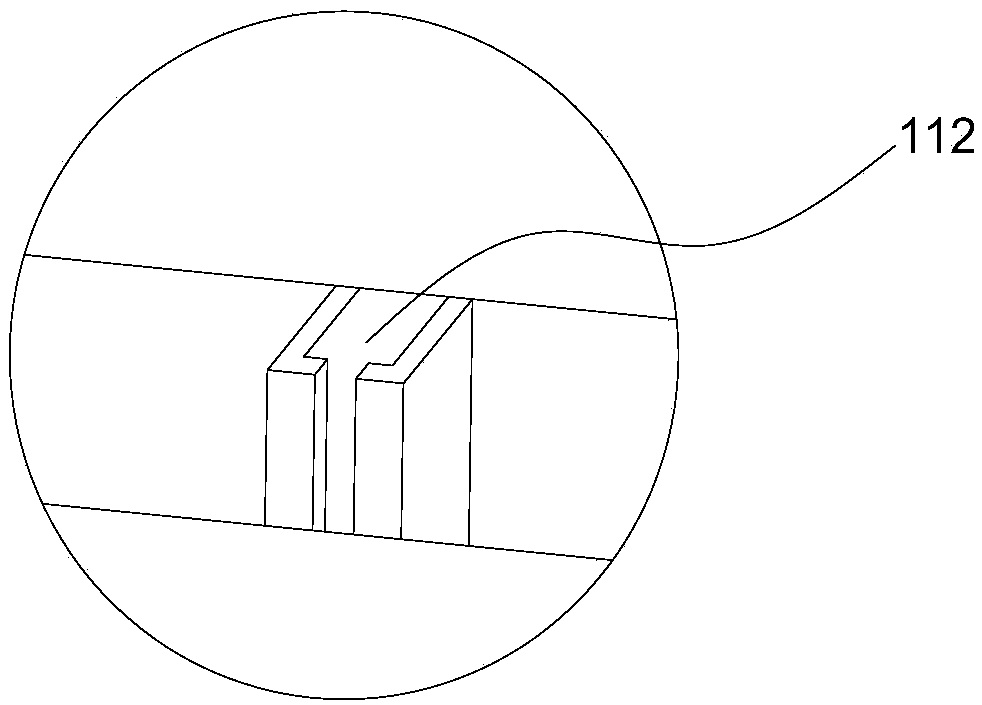

[0040] The difference between embodiment 2 and embodiment 1 lies in that the first sliding rails 112 on both sides of the tank body 110 are inclined. In this embodiment, the first sliding rails 112 are inclined at 45°. Therefore, when installing the gel plate 20, insert the gel plate 20 obliquely along the first slide rail 112 into the groove body 110, the resistance of the insertion process is relatively small, and at the same time, the electrophoresis buffer will not produce too many ripples . At the same time, when pulling out the gel plate 20, the gel plate 20 is pulled out of the tank body 110 obliquely along the first slide rail 112, the resistance in the pulling out process is relatively small, and at the same time, too much electrophoresis buffer will not be produced. ripple.

Embodiment 3

[0042] Embodiment 3 differs from Embodiment 1 in that: a first slide rail 112 is also provided on the inner wall of one side of the tank body 110 (that is, any side in the two sides perpendicular to the electric field line), and the first slide rail 112 The upper end of 112 extends to the top of the tank body 110. Correspondingly, one side of the gel plate 20 (that is, any one of the two sides perpendicular to the moving direction of the sample during electrophoresis) is correspondingly provided with an outwardly protruding slider. 21 , the slider 21 can slide up and down along the first slide rail 112 . By inserting the slider 21 arranged on the side of the rubber-making plate 20 into the first slide rail 112 on the side of the tank body 110, it also has the effect of fixing the rubber-making plate 20 by clamping, ensuring the stability of the electrophoretic strip. linearity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com