traction suspension system

A suspension system and component technology, applied in the direction of suspension, elastic suspension, electric power device, etc., can solve problems such as increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

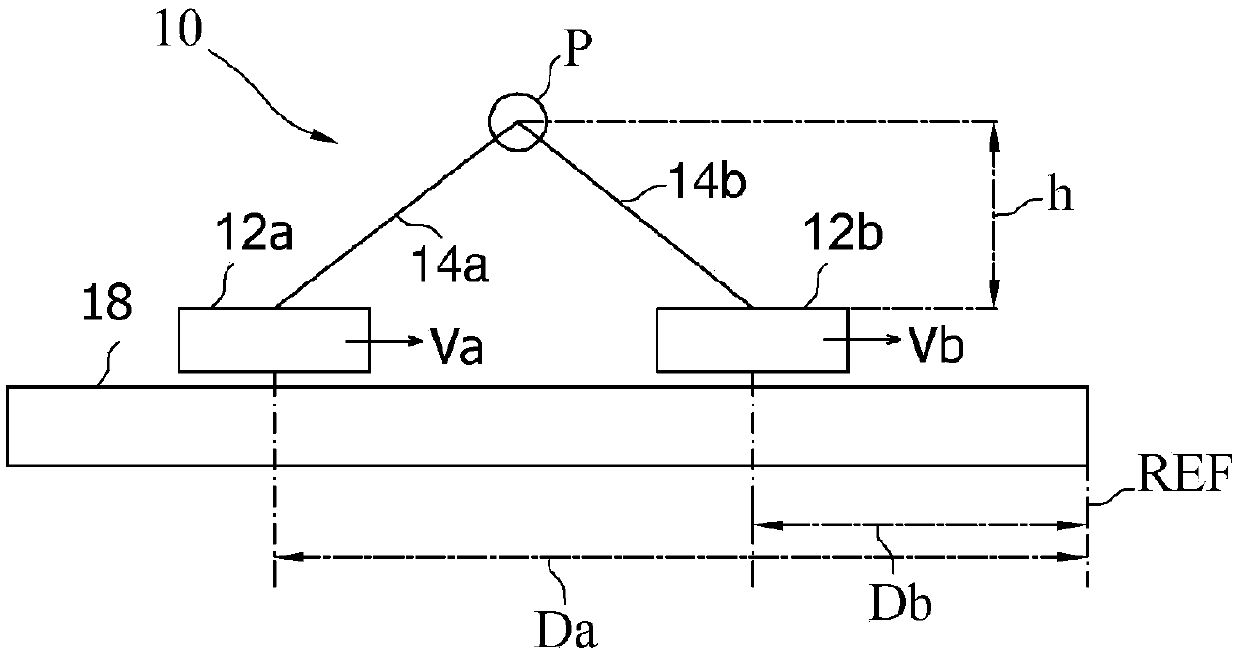

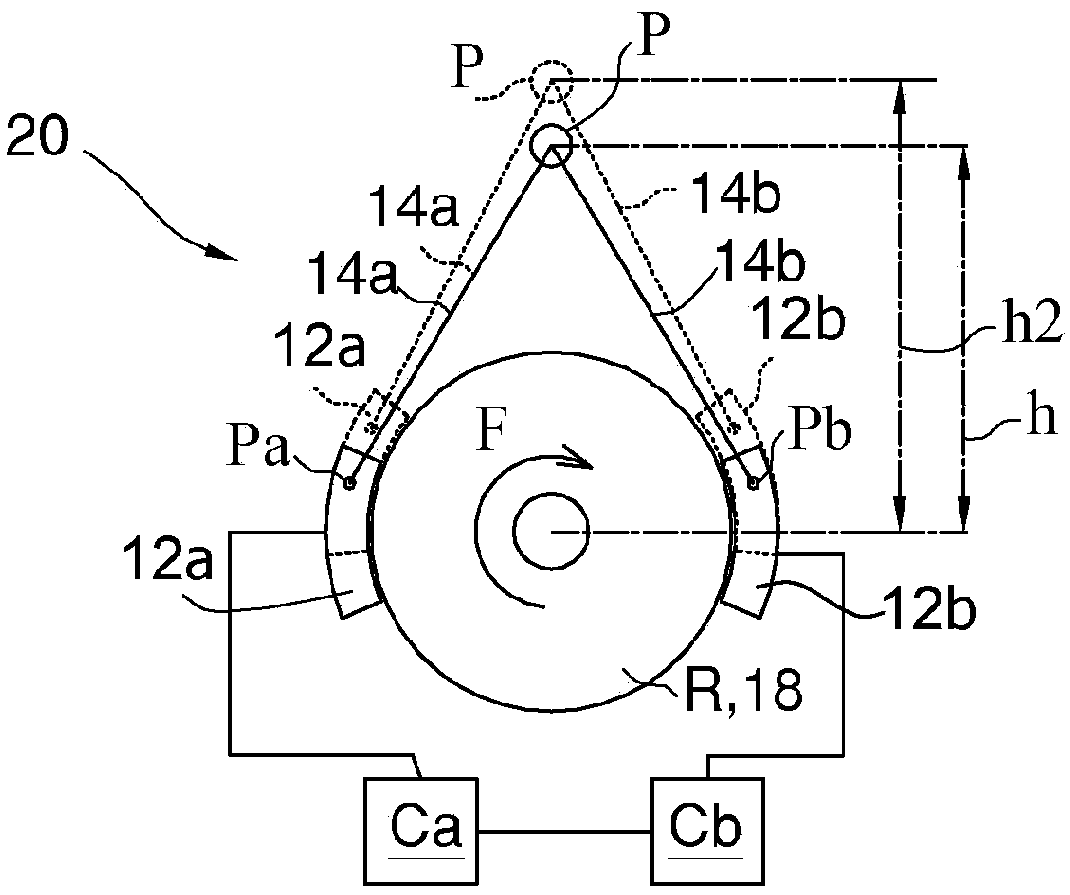

[0035] In order to understand the operation of the present invention, the basic principles are in figure 1 shown in . The system 10 comprises a track 12 on and relative to which the two units 12a, 12b can slide at relative velocities va, vb. The track has a zero reference REF, relative to which the cells 12a, 12b are at a distance Da, Db respectively. The speeds va, vb and / or the distances Da, Db are independently adjustable by control means (not shown).

[0036] Each unit 12a, 12b is connected to the same point P by a rigid arm 14a, 14b respectively. The point P is at a height h relative to the units 12a, 12b.

[0037] When the velocities va, vb are not equal, the speed difference will bring the units 12a, 12b closer or farther apart on the track 12, and thus the height h varies. Thus, by controlling the velocity va, vb and / or the distance Da, Db, the height h can be controlled.

[0038] Note that in system 10, the control of height h is independent of (i) the possible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com