Method and equipment for defining supporting structure for three-dimensional object to be made through stereolithography

A stereolithography, three-dimensional object technology, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve the problem of over-thick grid, large total volume of support structure, and insufficient total volume of support structure to properly provide three-dimensional support Objects and other issues, to achieve the effect of reducing costs and reducing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

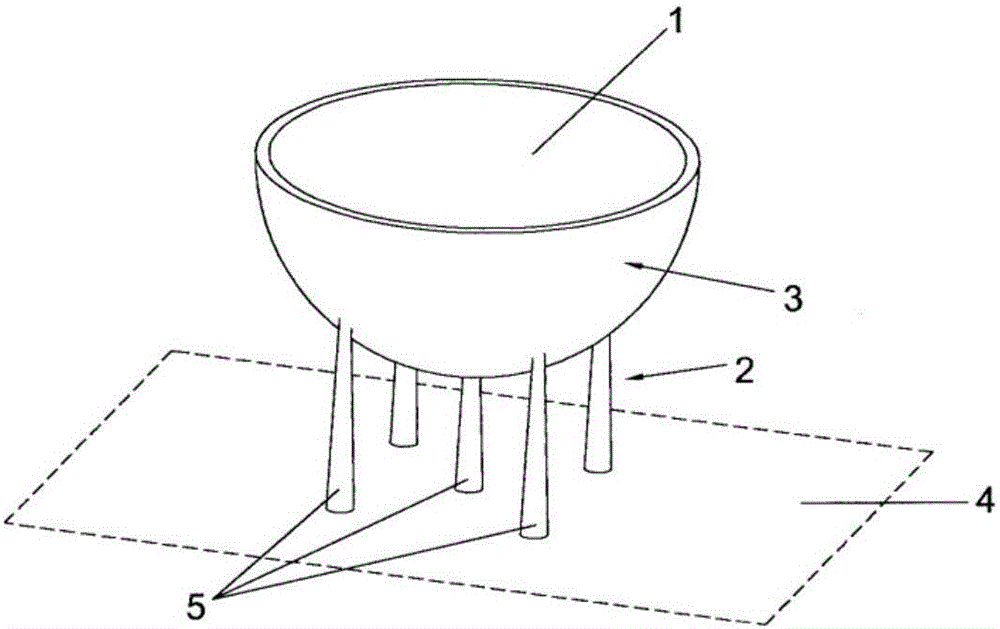

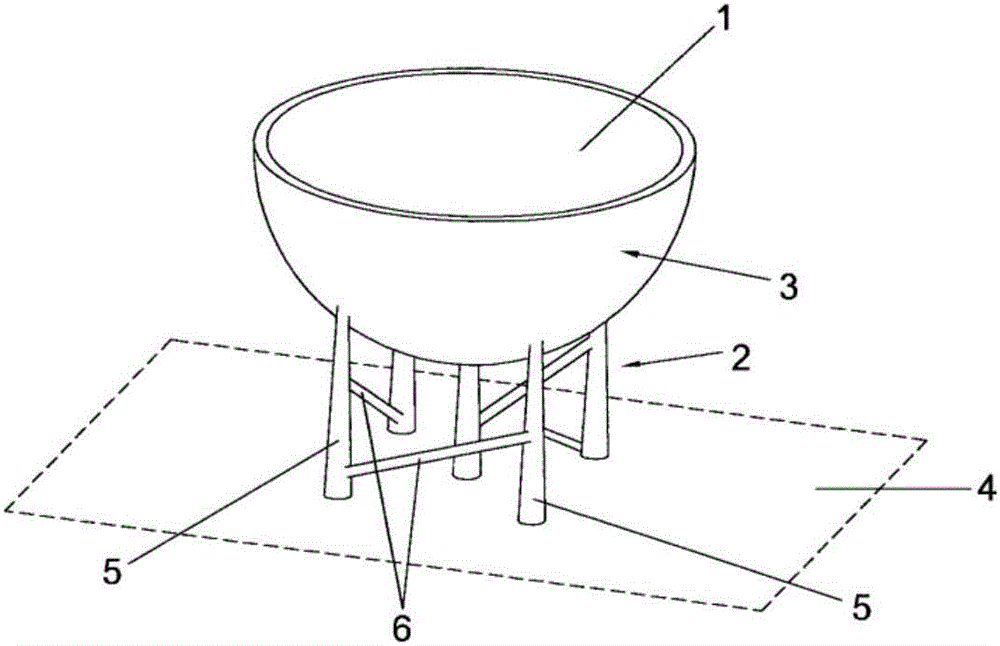

[0045] refer to figure 1 shown in and in figure 1 A three-dimensional object denoted by 1 in , describes the method of the invention for defining a support structure for a three-dimensional object to be produced by stereolithography.

[0046] It should thus be noted that the three-dimensional object 1 has deliberately been shown with a very simplified geometry compared to objects usually produced by stereolithography, in order to make the drawing clearer.

[0047] However, it is evident that the description provided above can be similarly applied to three-dimensional objects of any geometry.

[0048] Firstly, the method comprises the step of defining a first surface 3 belonging to a three-dimensional object 1 to be supported.

[0049] Obviously, if necessary, a plurality of said first surfaces to be supported can be defined depending on the geometry of the object, the materials used in the stereolithography process and other parameters.

[0050] Obviously, the method of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com