Intelligent mold adjusting and pressurizing equipment of tire vulcanizing machine

A technology of tire vulcanization and pressurization equipment, applied in tires, other household appliances, household appliances, etc., can solve the problems of long auxiliary time for mold replacement, affecting tire quality, uneven force on molds, etc., shortening manual assistance time, eliminating Equipment hidden dangers and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

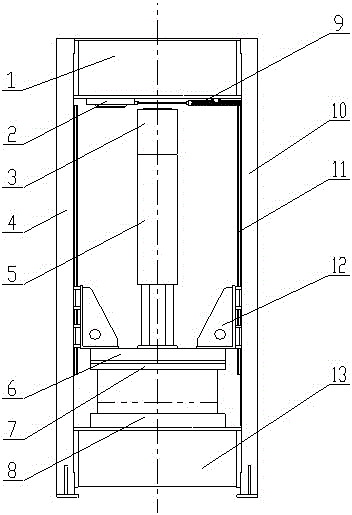

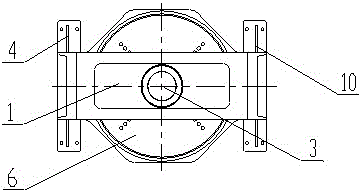

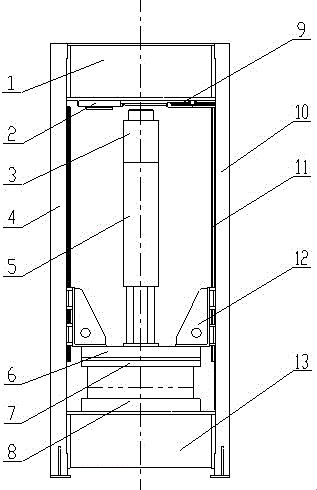

[0020] combined with Figure 1-2 , to further describe the present invention:

[0021] An intelligent mold adjustment and pressurization equipment for a tire vulcanizer mentioned in the present invention includes a beam 1, a mold adjustment booster cylinder 3, a left frame 4, a column 5, an upper supporting plate 6, an upper heating plate 7, and a lower heating plate 8. The right frame 10, the linear guide rail 11, the guide seat 12, and the base 13, the beam 1, the base 13, the left frame 4, and the right frame 10 constitute a frame, forming a closed force-bearing structure , the top of left side frame 4, right side frame 10 is provided with crossbeam 1, and bottom is provided with base 13; Plate 7 is installed on the bottom of upper supporting plate 6, and the tire upper mold is installed on the underside of upper hot plate 7, and two guide seats 12 are installed on both sides of upper supporting plate 6, on the left side frame 4, the right side frame A linear guide rail 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com