Thresher vibrating screen bearing and shock absorbing mechanism

A technology of vibration reduction mechanism and vibrating screen, which is applied in the direction of threshing equipment, agricultural machinery and implements, etc. It can solve the problems of large vibration of implements, increase the wear of suspenders, and reduce the service life of implements, so as to achieve long service life and lighten implements. Effect of reducing wear and tool vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

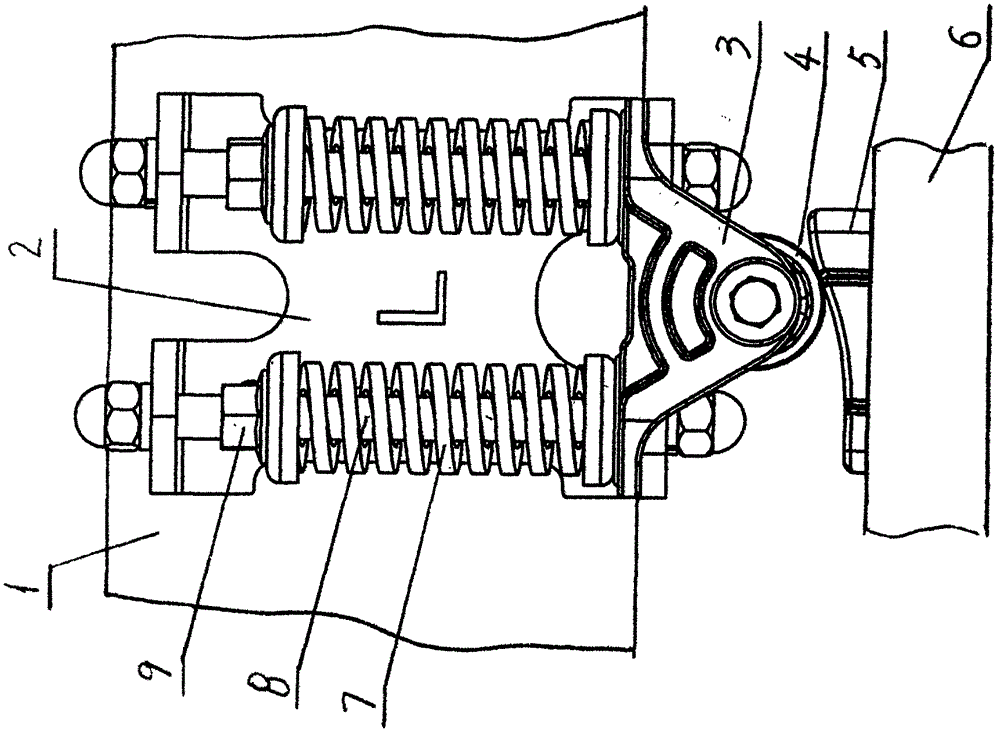

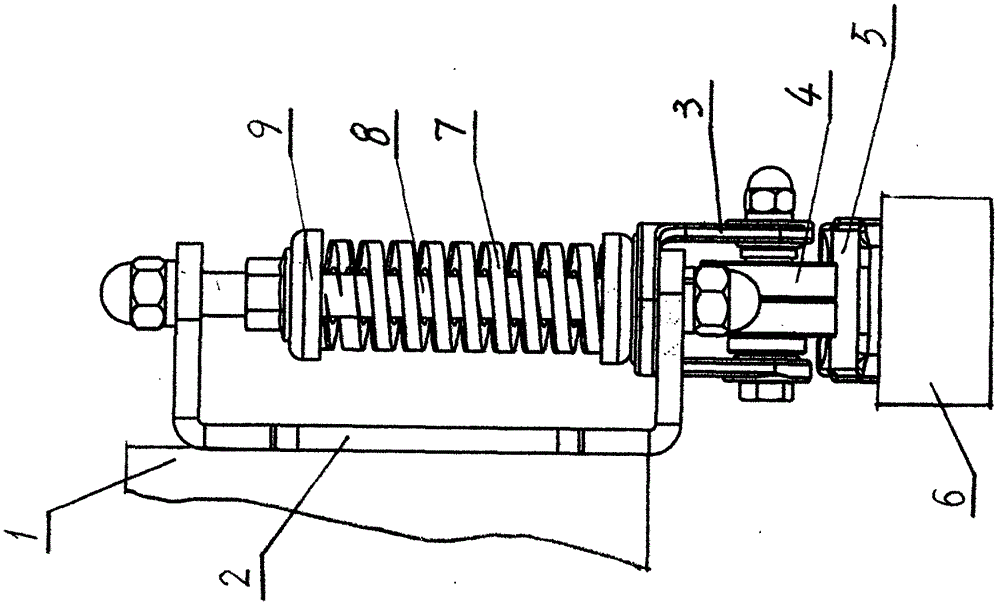

[0010] The following describes the creative implementation of the present invention in detail with reference to the accompanying drawings. A thresher vibrating screen load-bearing vibration reduction mechanism includes a vibrating screen 1 and a frame 6. A vibration damping frame 2 is fixedly mounted on the side of the vibrating screen 1, and the vibration damping frame 2 is fixedly mounted vertically parallel to each other Two threaded guide rods 8, on the lower side of the two threaded guide rods 8, are fitted with a roller seat 3 that can be moved up and down, and a damping spring 7 and a pressure are respectively installed on the two threaded guide rods 8 Adjusting nut 9, the upper and lower end surfaces of the damping spring 7 are in contact with the pressure adjusting nut 9 and the roller seat 3 respectively. The upper end of the damping spring 7 is axially locked on the threaded guide rod 8 by the pressure adjusting nut 9, and the roller 4 is fitted on a roller seat 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com