Stirring cup driven by heat energy

A stirring cup and thermal energy technology, applied in the field of cups, can solve problems affecting the practicality and aesthetics of the cup, affecting the installation space of the stirring device, and increasing the thickness of the bottom of the cup, so as to achieve convenient and thorough cleaning, increase power generation, and increase heat. The effect of the exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

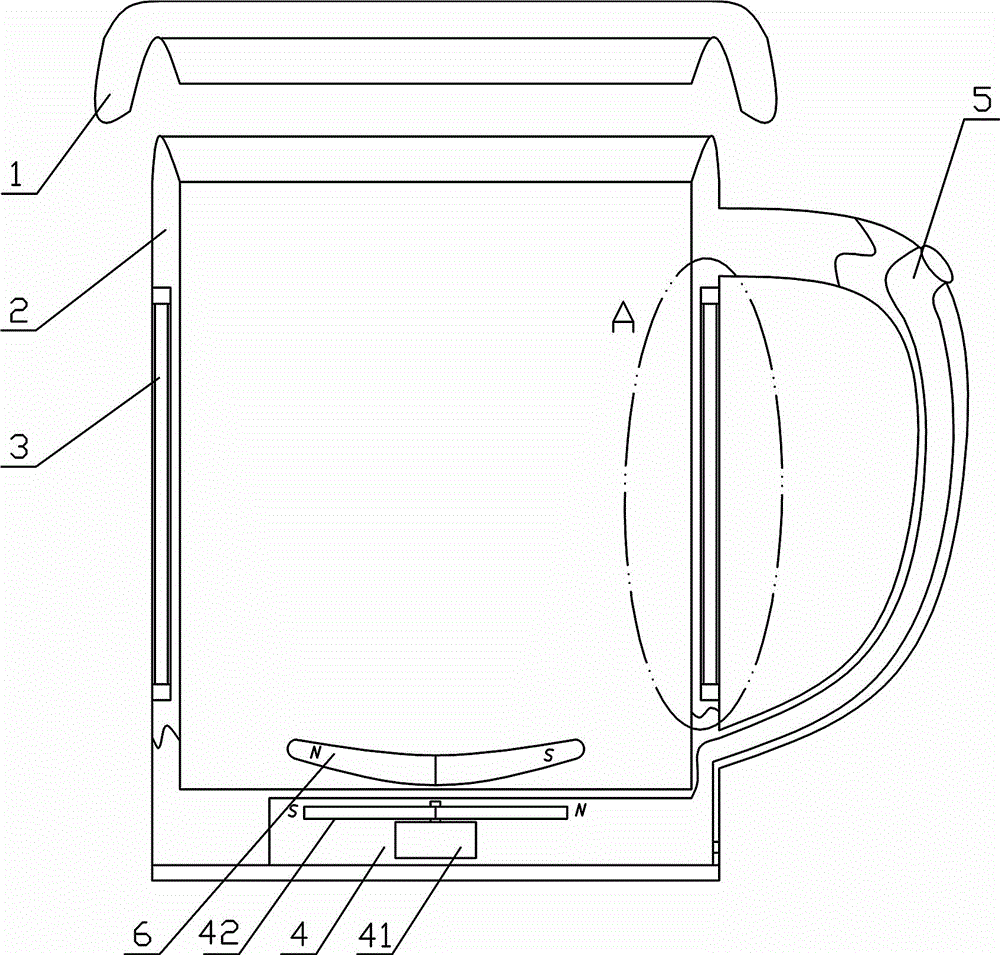

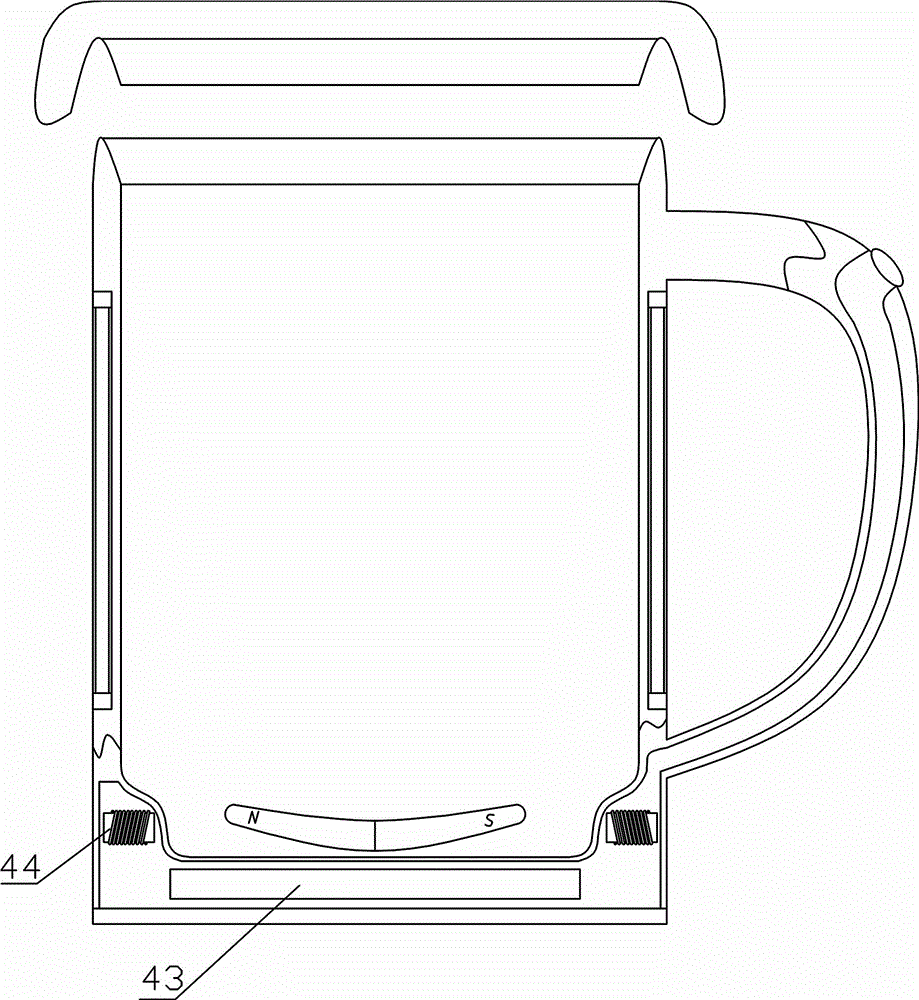

[0026] like figure 1 , 3 Among them, a stirring cup driven by heat energy includes a cup body 2, preferably also provided with a cup cover 1, and a thermal insulation layer is provided inside the cup cover 1. A power generating device is arranged in the cup body 2, and the generating device is connected with the stirring device;

[0027] The power generation device includes a thermoelectric power generation sheet 33 .

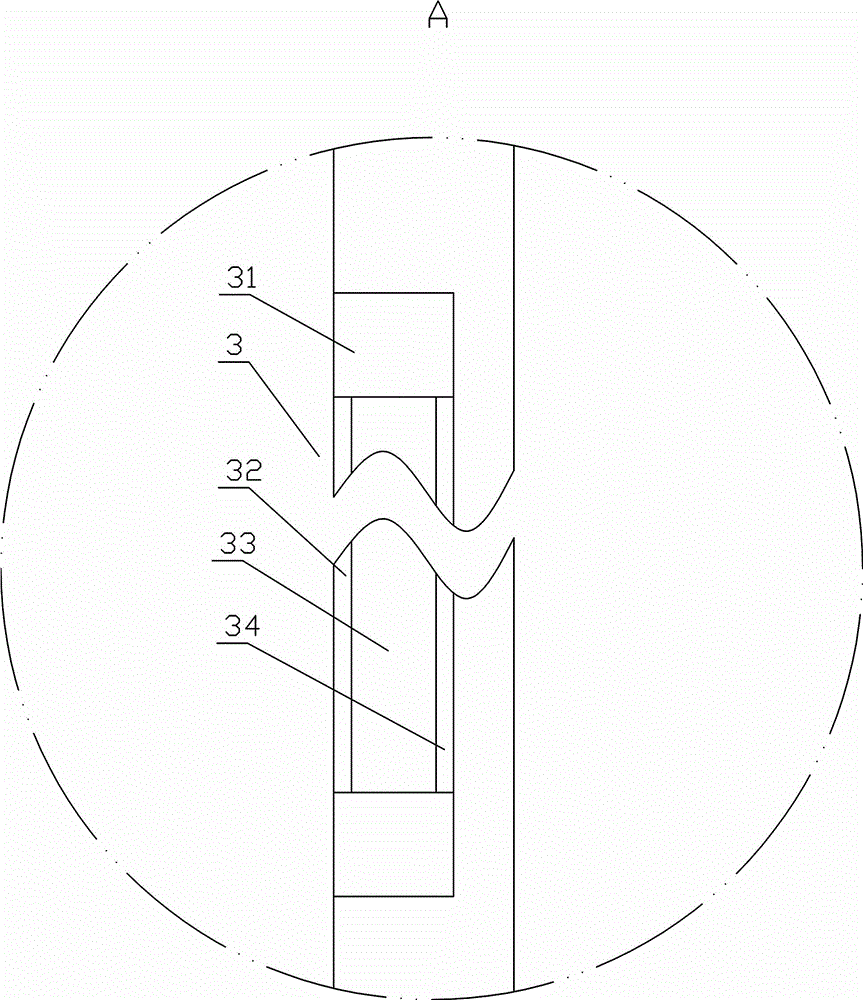

[0028] The preferred solution is as figure 2 Among them, in the power generation device described above, the thermoelectric power generation sheet 33 is located in the side wall of the cup body 2, and the inner and outer layers of the thermoelectric power generation sheet 33 are respectively provided with an inner layer heat conduction sheet 34 and an outer layer heat conduction sheet 32, and the thermoelectric generation sheet 33 The upper end and the lower end are provided with a heat insulating layer 31 . The material of the inner layer heat conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com