Dynamic Headspace Degasser

A technology of dynamic headspace degassing and degassing tank, which is applied in the direction of measuring devices, liquid degassing, material inspection products, etc., which can solve the problem that the long equilibration time can not quickly respond to the change of insulating oil components, affect the insulation performance of insulating oil, and ensure reliability. Poor performance and unsuitable problems, to achieve the effect of low cost, good air tightness and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

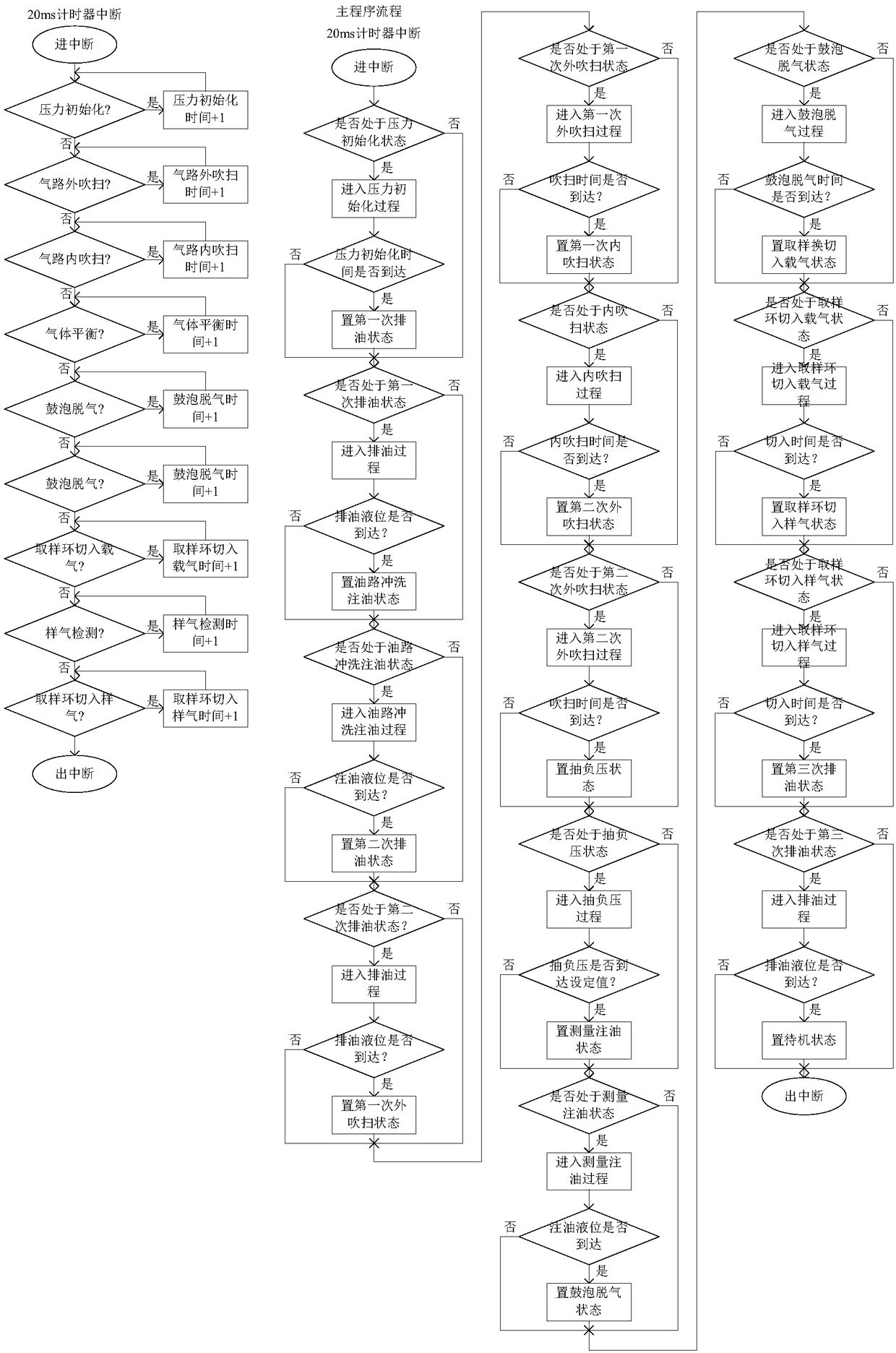

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

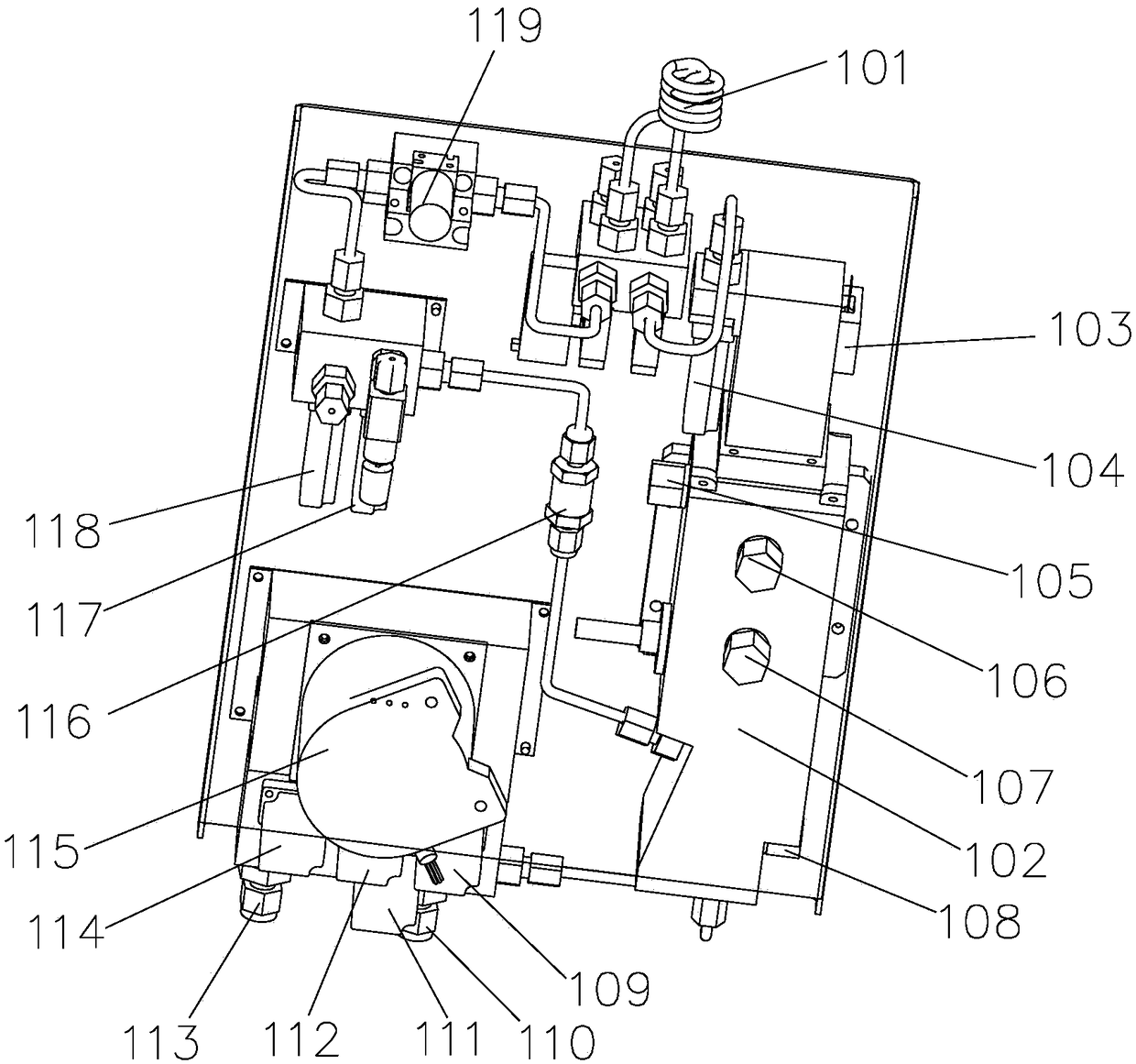

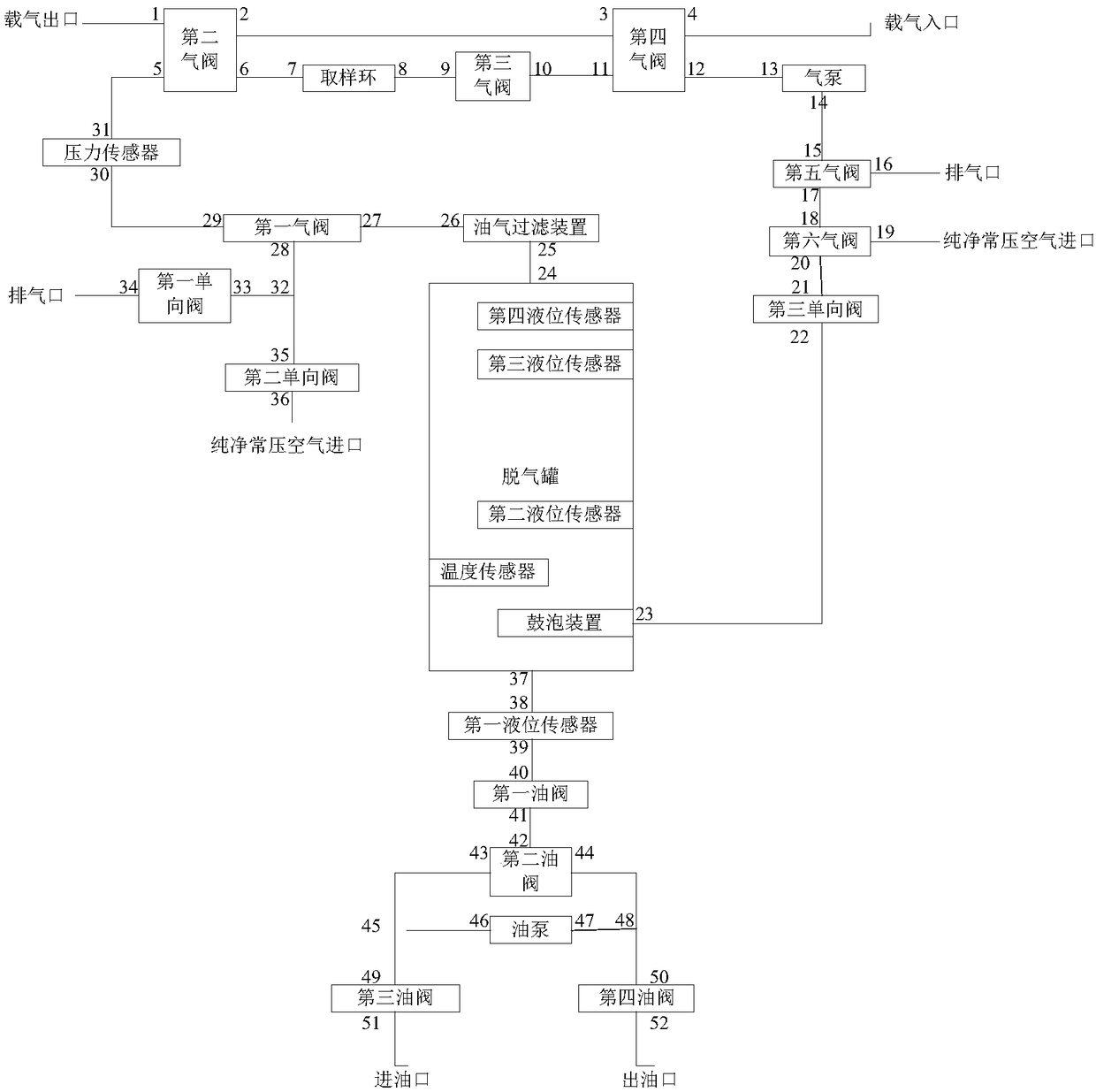

[0026] like figure 1 , figure 2 As shown, the dynamic headspace degassing device of the present invention includes a degassing tank 102, a gas circuit part and an oil circuit part. The gas circuit part and the oil circuit part are respectively connected with the degassing tank 102, and the bottom of the degassing tank 102 is provided with a bubbling device. A temperature sensor is provided at the bottom of the degassing tank 102 .

[0027] The gas path part includes a circulation pipeline, and the circulation pipeline is provided with a first air valve 104, a second air valve 118, a sampling loop 101, a third air valve 117, a fourth air valve, an air pump 119, a fifth air valve and a fourth air valve. Six air valves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com