Rice hulling linkage and adjustment mechanism of household small grain processing machinery

A technology of processing machinery and regulating mechanism, which is applied in application, grain processing, grain pod removal, etc. It can solve the problems of inability to adjust the grain export channel and inconvenient adjustment of the gap between rubber rollers, so as to improve the quality and efficiency of husking and high-efficiency husking Processing, easy and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with specific embodiment:

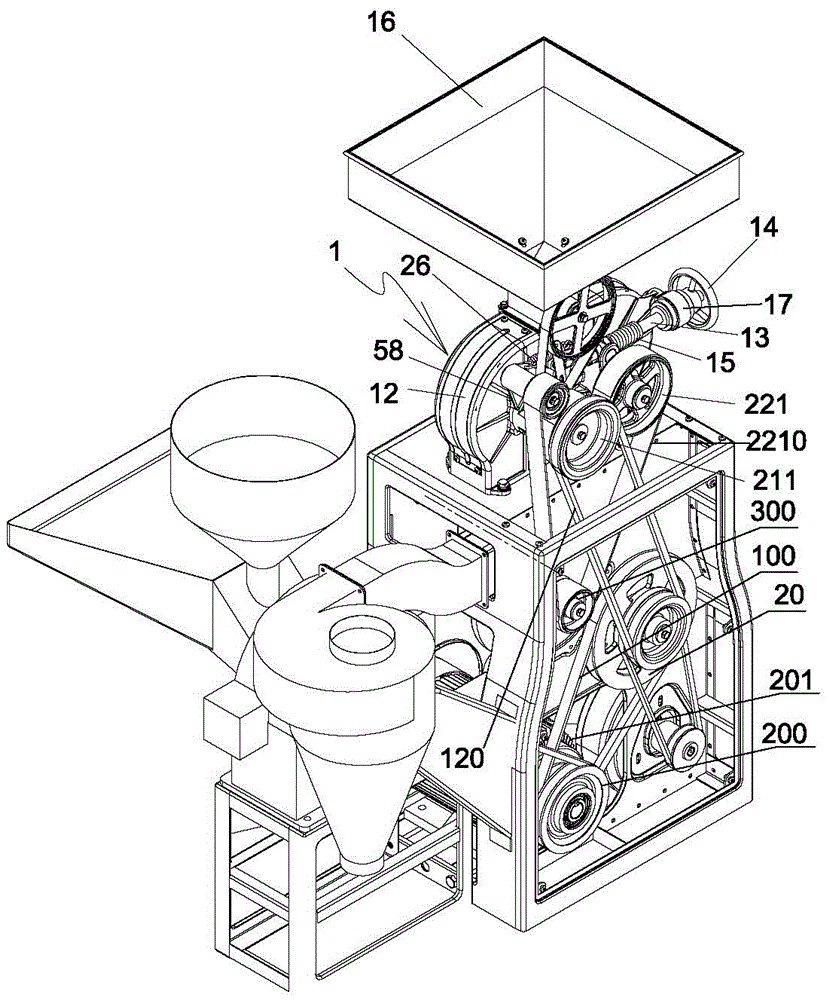

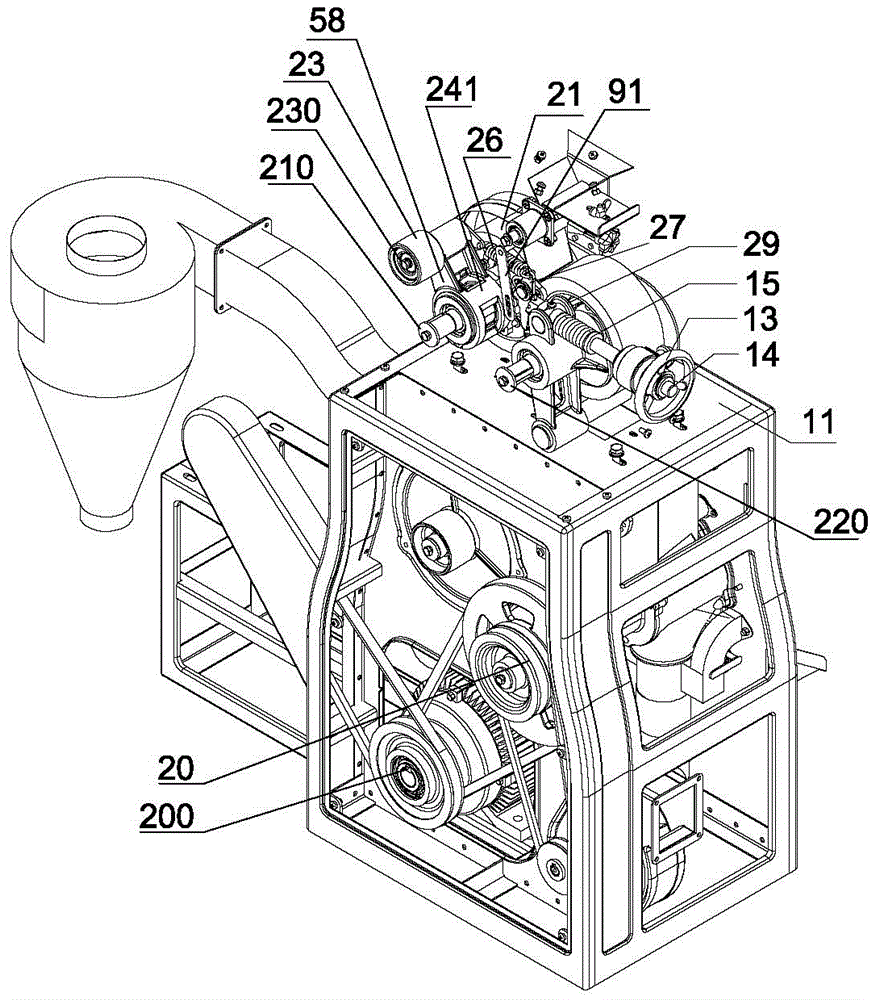

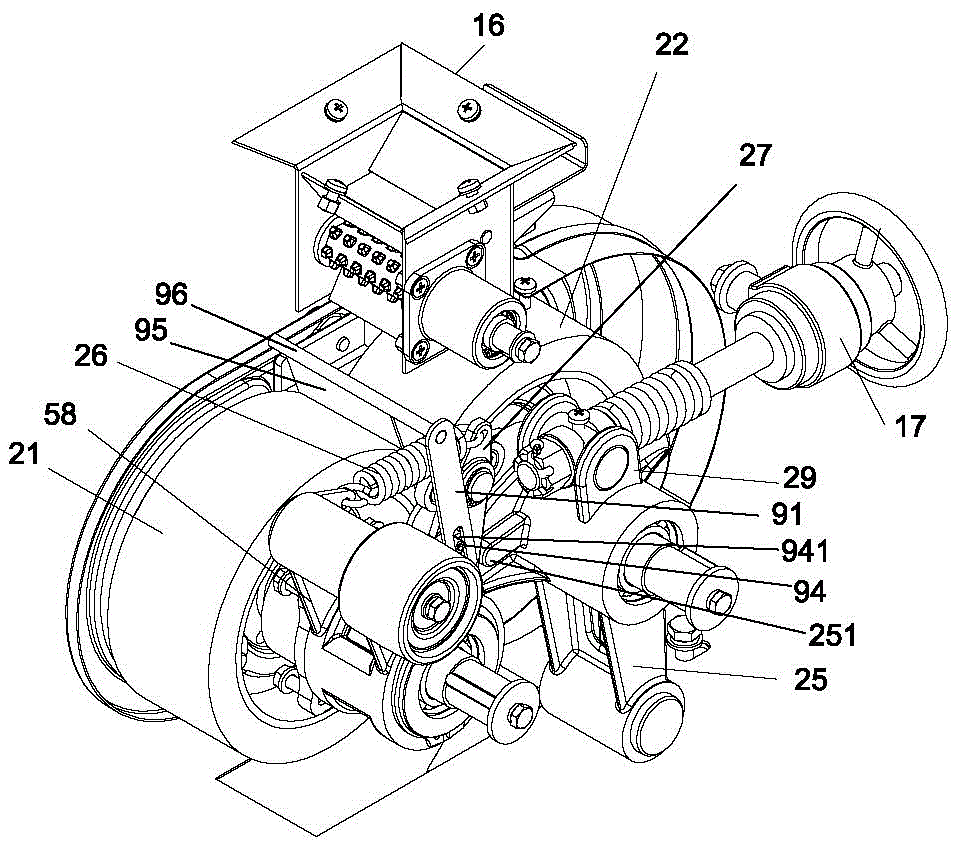

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a household small-scale grain processing machinery husking linkage adjustment mechanism includes a husker head 1, a rice mill pulley 211, a main rubber roller pulley 221 and a tension pulley 23, and a feeder is installed above the husker head 1. The bucket 16 is provided with a main rubber roller 21 and a secondary rubber roller 22 in the shell 12 of the huller head 1, and the tensioning wheel 23 is fixed on the tensioning wheel shaft 230, which is pivotally mounted on the tensioning wheel pendulum The swing end of the arm 58 and the root of the tension wheel swing arm 58 are provided with a hinge sleeve 241, the main rubber roller shaft 210 of the main rubber roller 21 is pivotally mounted on the shell 12 of the huller head 1, and the hinge sleeve 241 is set The main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com