Automatic helmet cleaning and managing machine

An automatic cleaning and safety helmet technology, applied in cleaning methods and utensils, cleaning methods using tools, removing smoke and dust, etc., can solve the problem of safety helmets without special management and cleaning equipment, etc., to avoid loss or mixing, and ensure comfort. Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

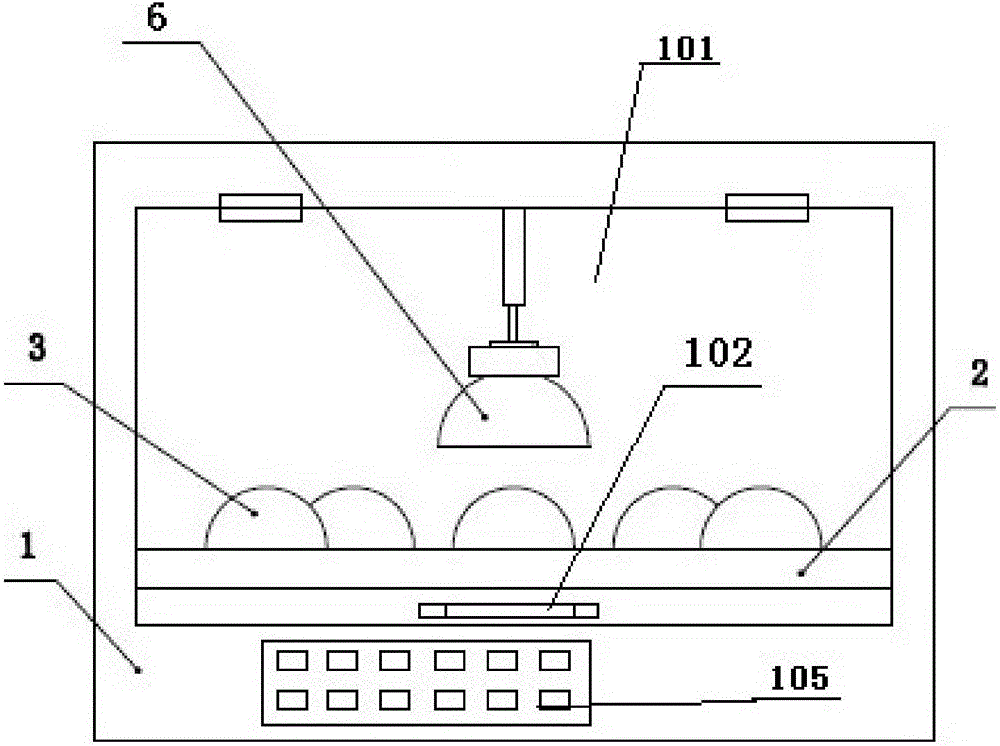

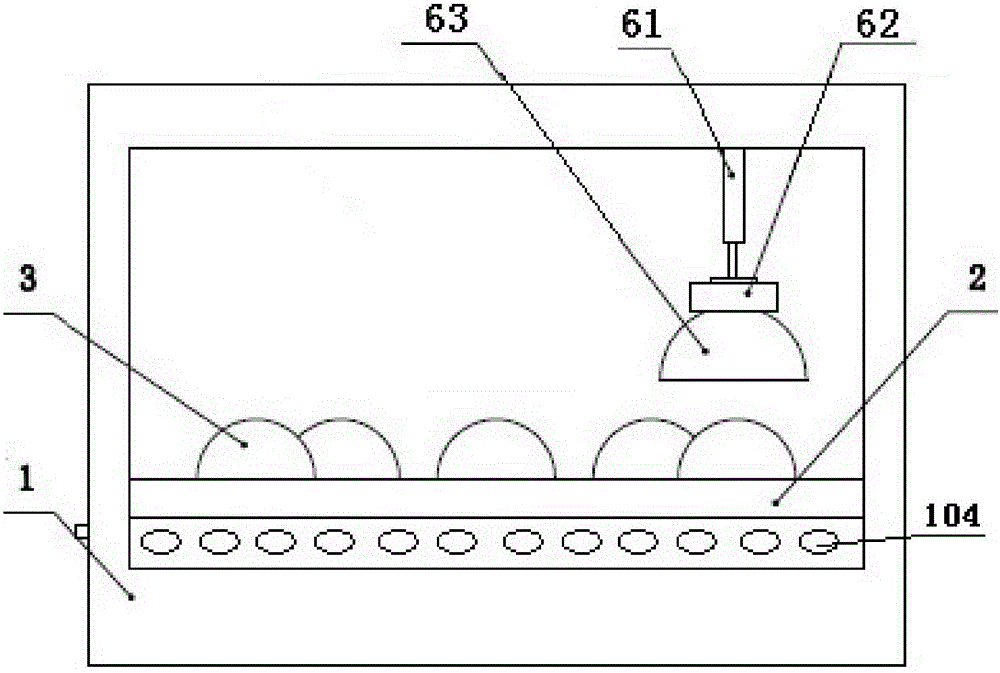

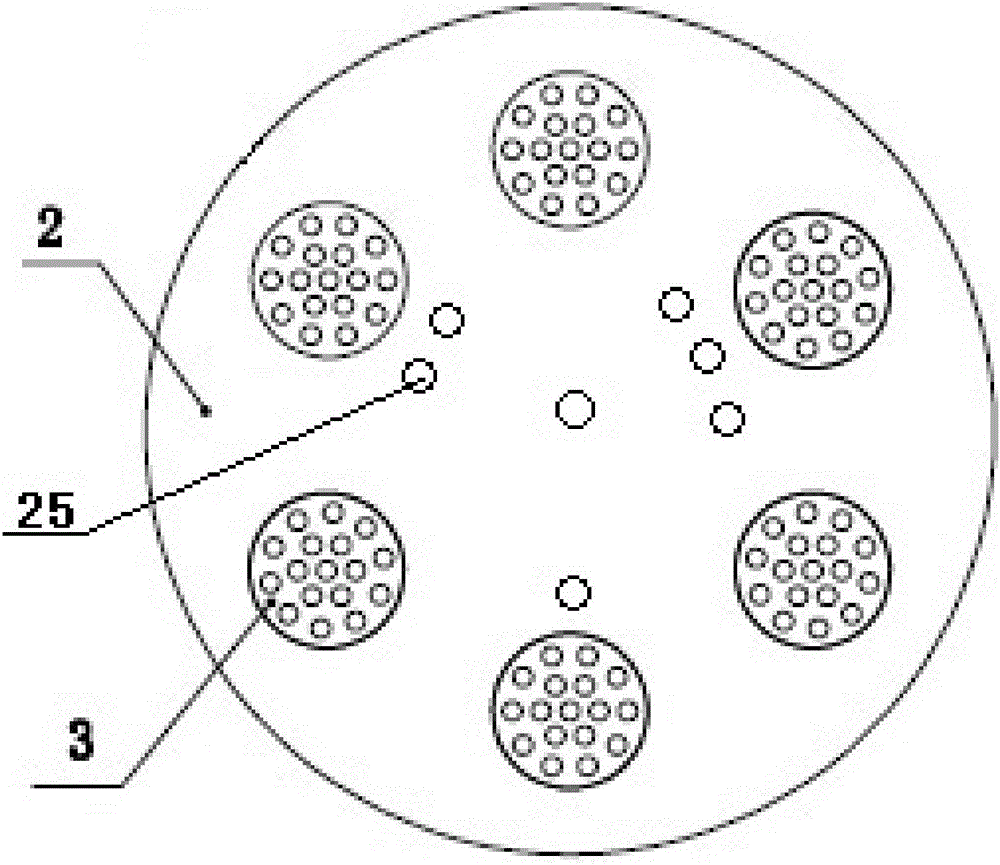

[0030] Figure 1 to Figure 5 is an embodiment of the present invention, such as figure 1 As shown, a safety helmet automatic cleaning management machine includes a box body 1, a turntable 2, a support mold 3, and a wiper 6. A glass window 101 is arranged on the front of the box body 1, and a support plate 103 is arranged in the box body 1. The turntable 2 Installed on the support plate 103, a plurality of support molds 3 are provided, and each support mold 3 is distributed on the turntable 2 along the uniform circumference of the center of the turntable 2, and the wiper 6 is arranged on the top of one of the support molds 3; The door is installed on the box body 1, and the glass window 101 is provided with a handle 102. An operation panel 105 is also provided on the front of the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com