Box conveyer and foundry production system

A case feeder and frame technology, which is applied in the field of foundry production systems, can solve the problems of difficult accurate positioning, large differences in the size of the sand box, and long process time, and achieves the effect of being beneficial to the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

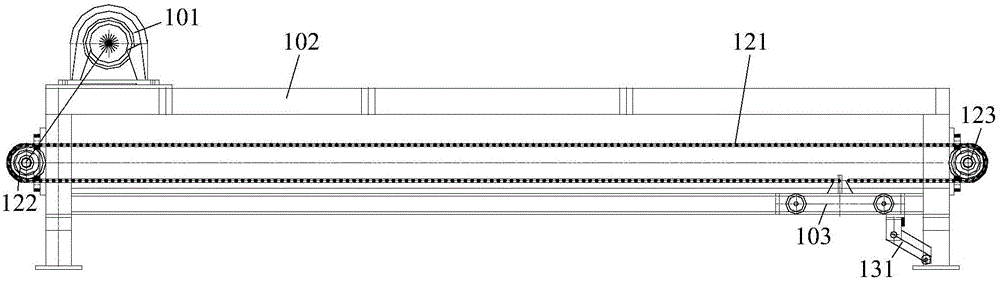

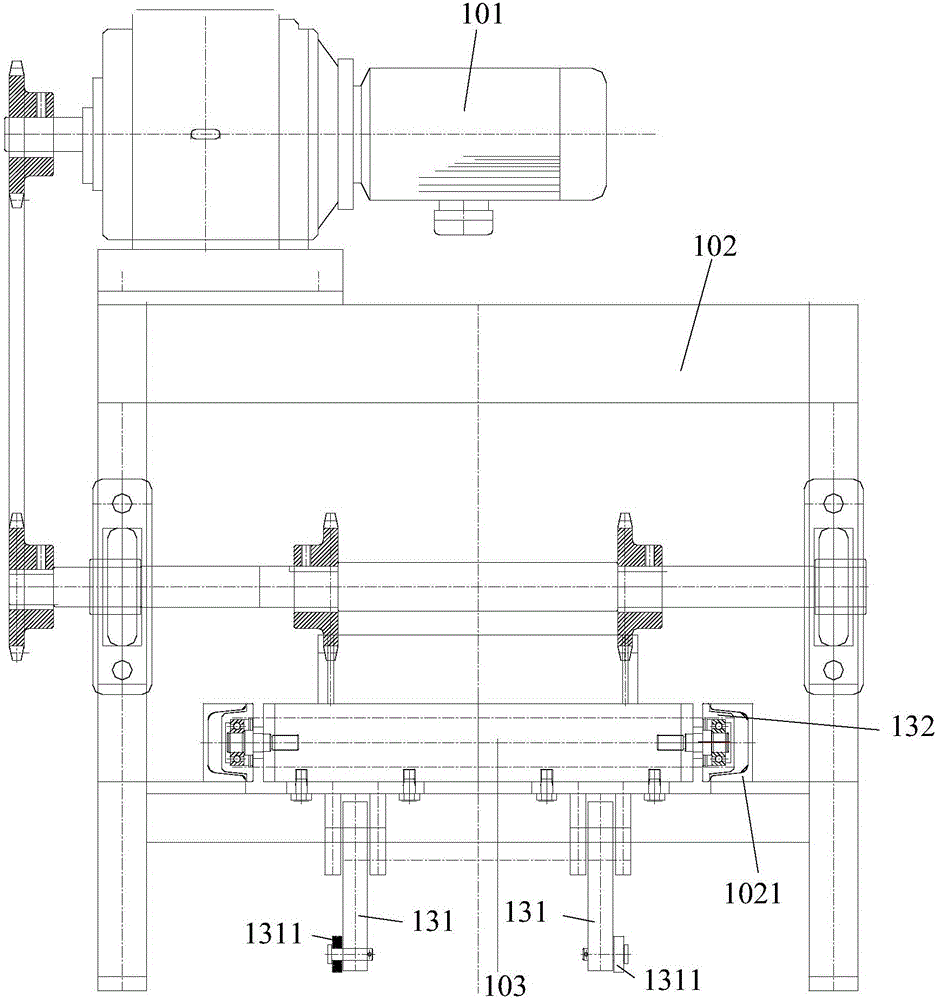

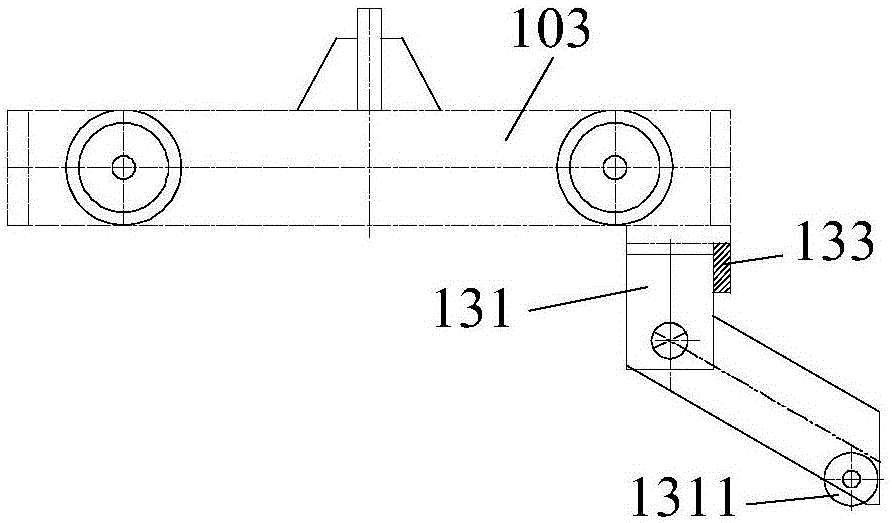

[0033] The embodiment of the present invention discloses a box feeding machine, which can transport one or more sand boxes individually, avoiding the transportation of the sand boxes on the entire casting production line one by one, reducing or even avoiding the effects of thermal expansion and cold contraction of the sand boxes. The influence of the accuracy of conveying to the station is beneficial to the operation of the sand box at the station. The embodiment of the present invention also discloses a casting production system, which uses the above-mentioned box feeder, and the sand boxes can be accurately positioned on the work station after being transported by the box sender, so that the user can perform operations at the work station.

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com