Aircraft thin plate countersunk hole cutting device

A cutting device and countersunk hole technology, applied in portable drilling rigs, drilling/drilling equipment, metal processing, etc., can solve the problems of reduced aerodynamic smoothness, rework, and uneven appearance of screw fasteners, etc., to achieve improved Machining accuracy, improving efficiency, and avoiding the effect of uneven appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

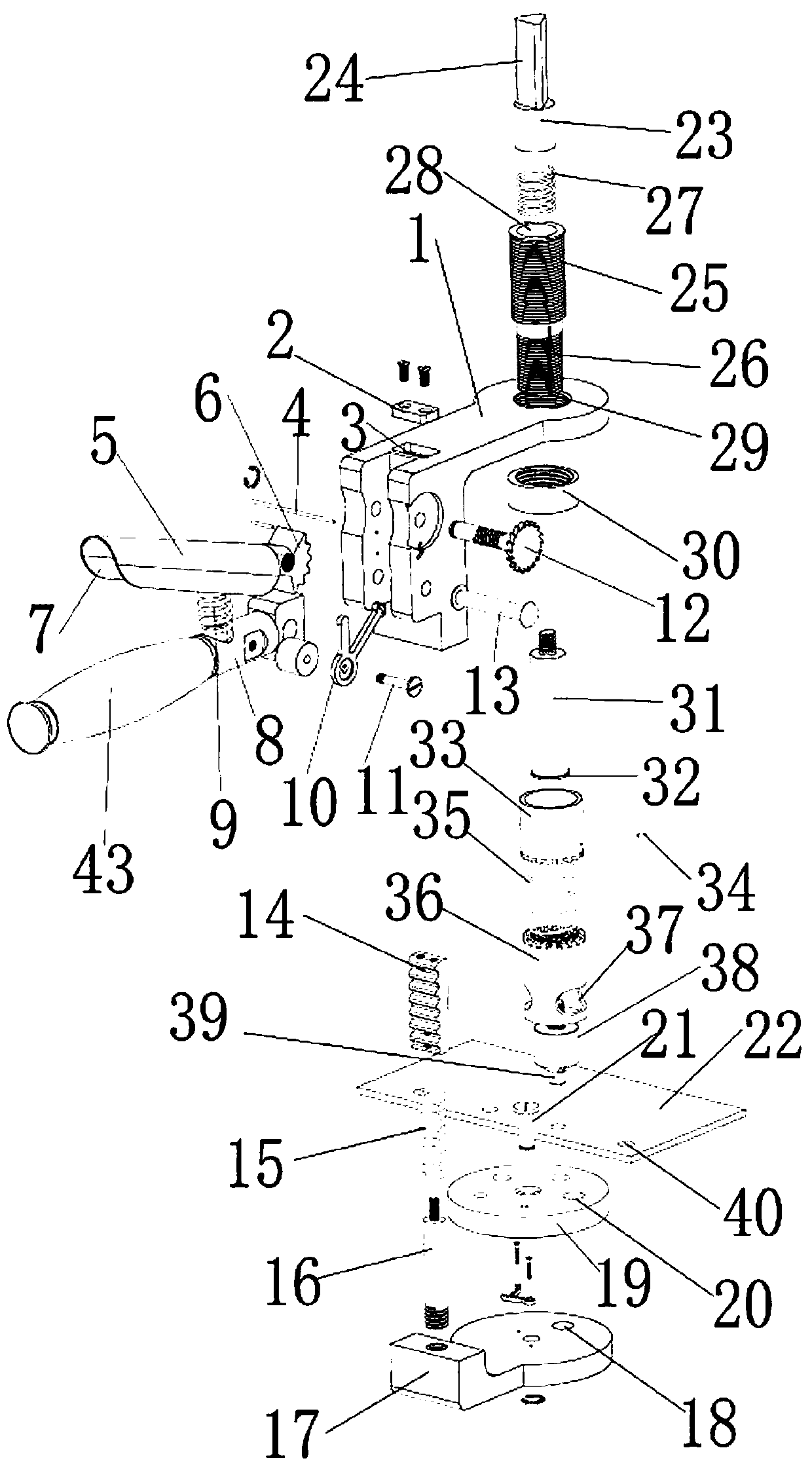

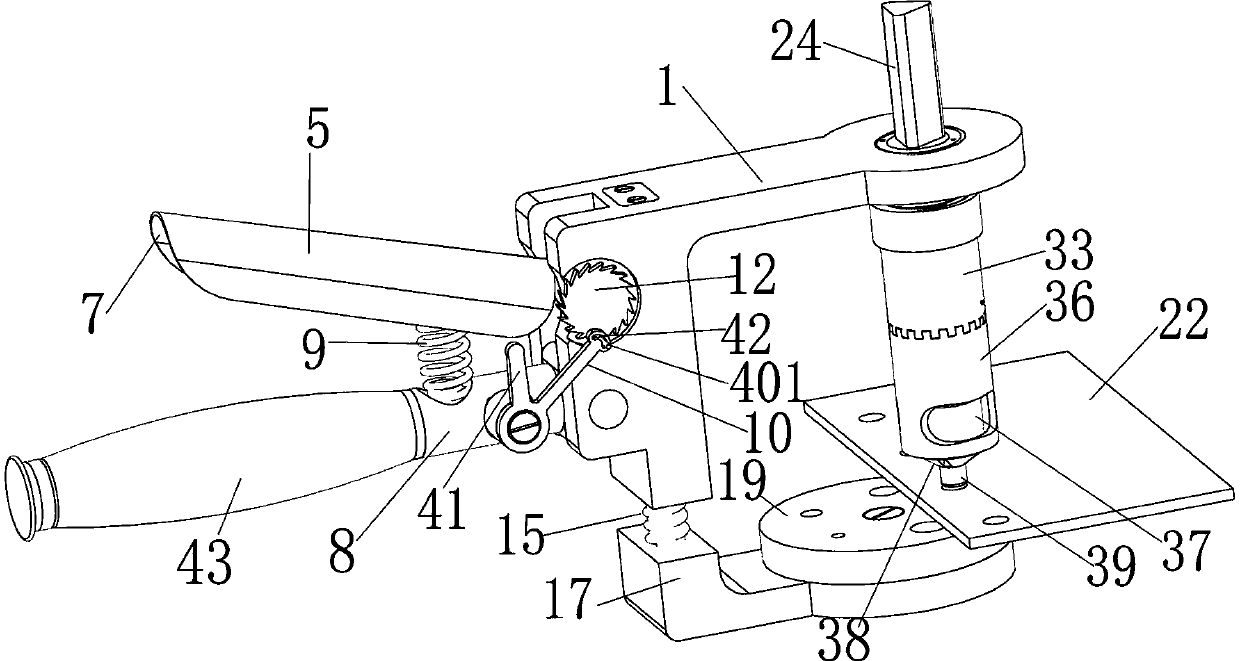

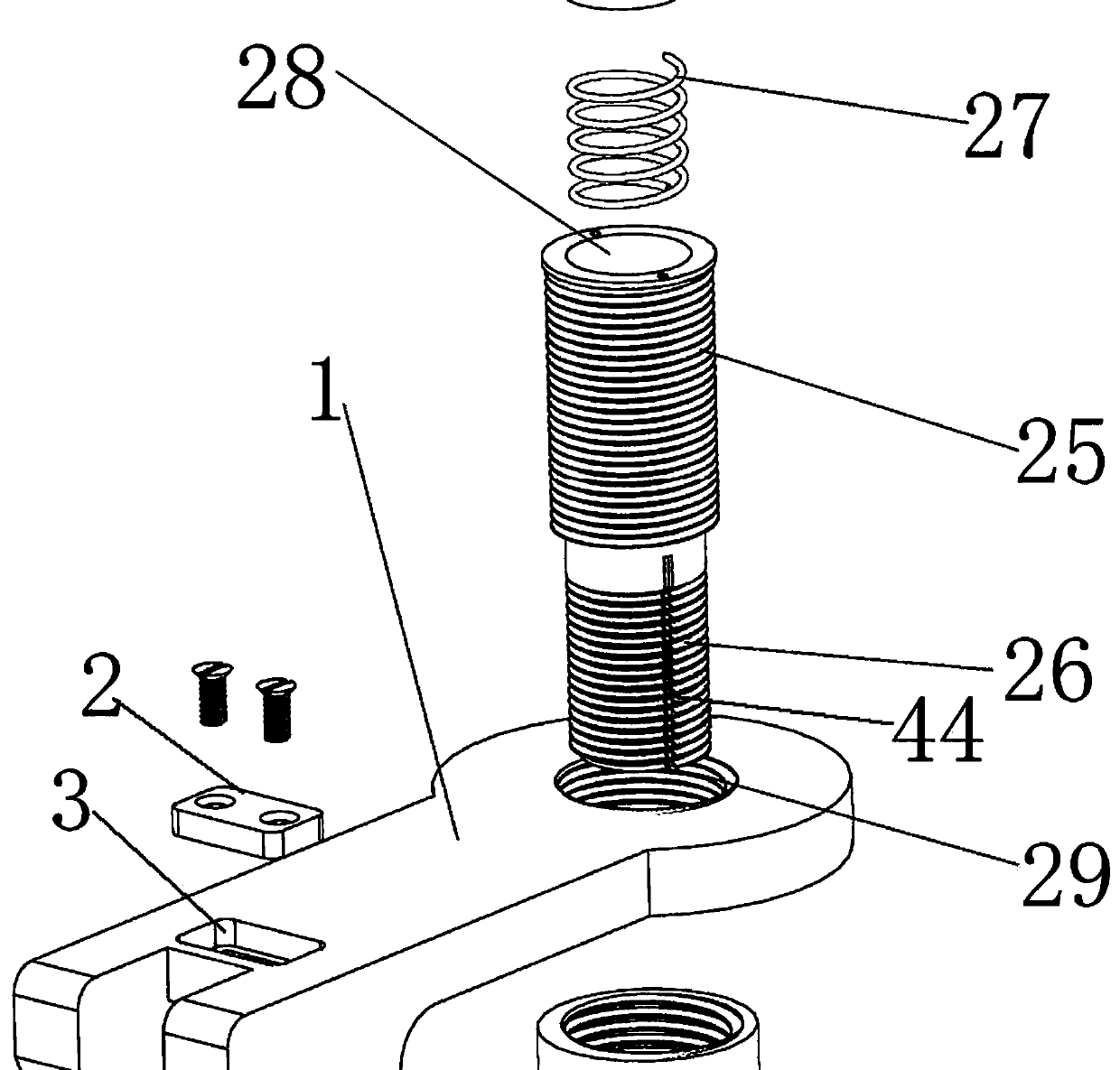

[0030] Attached below figure 1 to attach Figure 6 The present invention will be further described.

[0031] An aircraft sheet countersink cutting device, comprising: an upper base 1, which is used to clamp the upper surface of a sheet material 22; a lower base 17, which is vertically slid and inserted into the lower end of the upper base 1 through a shaft rod 16, Used to clamp the lower surface of the thin plate 22; the lower base driving mechanism is installed on the upper base 1, and is used to drive the lower base 17 to move up and down relative to the upper base 1; the threaded sleeve 25 is vertically screwed on the In the threaded hole I 29 on the upper base 17; the slide rod 23 is slid and inserted in the socket 28 of the threaded sleeve 25 in the axial direction, and its head end is provided with a triangular rod 24, and between its lower end and the socket 28 A spring III 27 is provided; and a countersink cutting tool 38 is located on the upper end of the thin plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com