Slotted pressure pliers for main drive lock nut

A main reducer and lock nut technology, which is applied to nuts, lock fasteners, screws, etc., can solve problems such as manual locking difficulties, achieve the effect of protecting workpieces and operating safety, and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

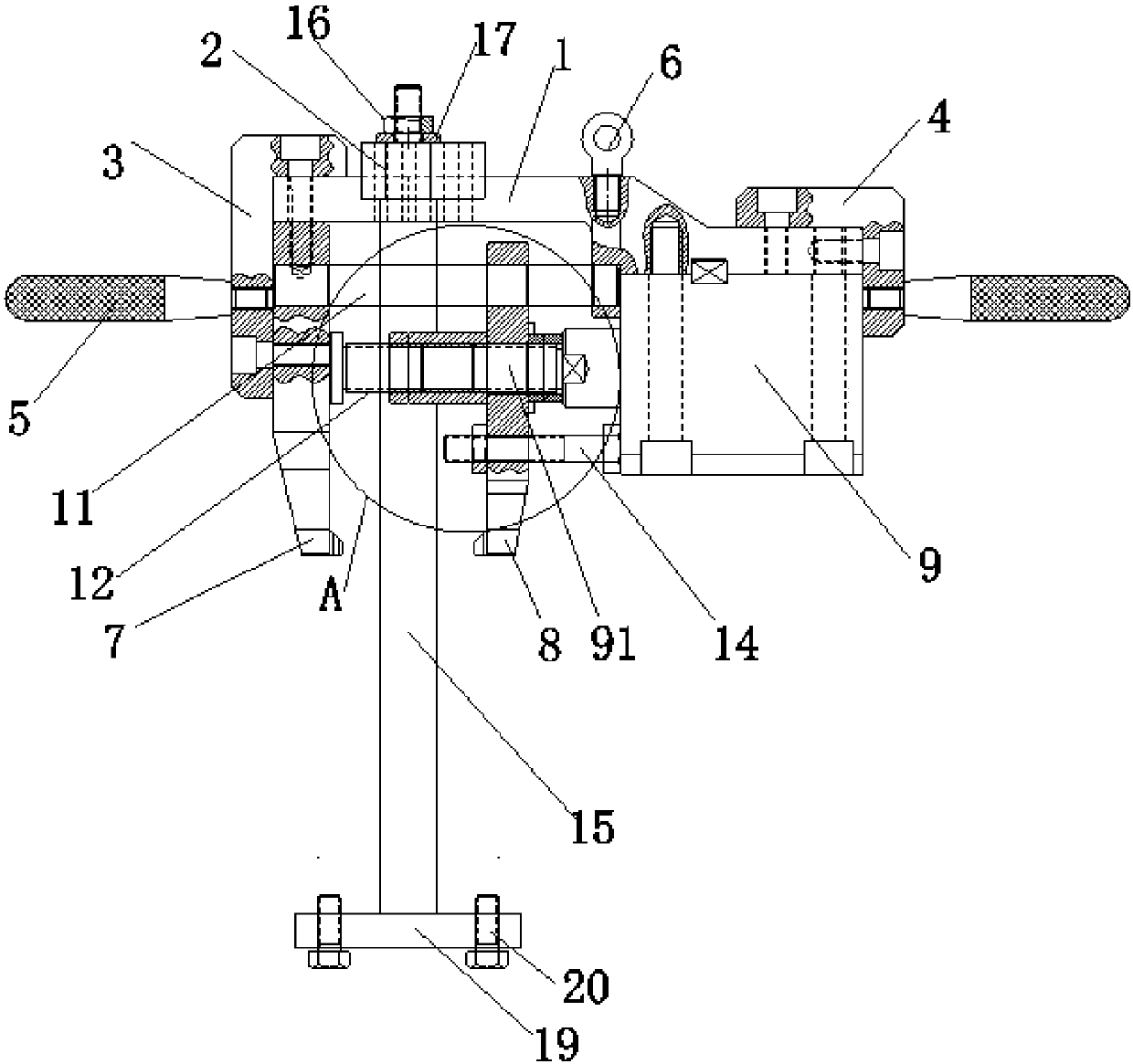

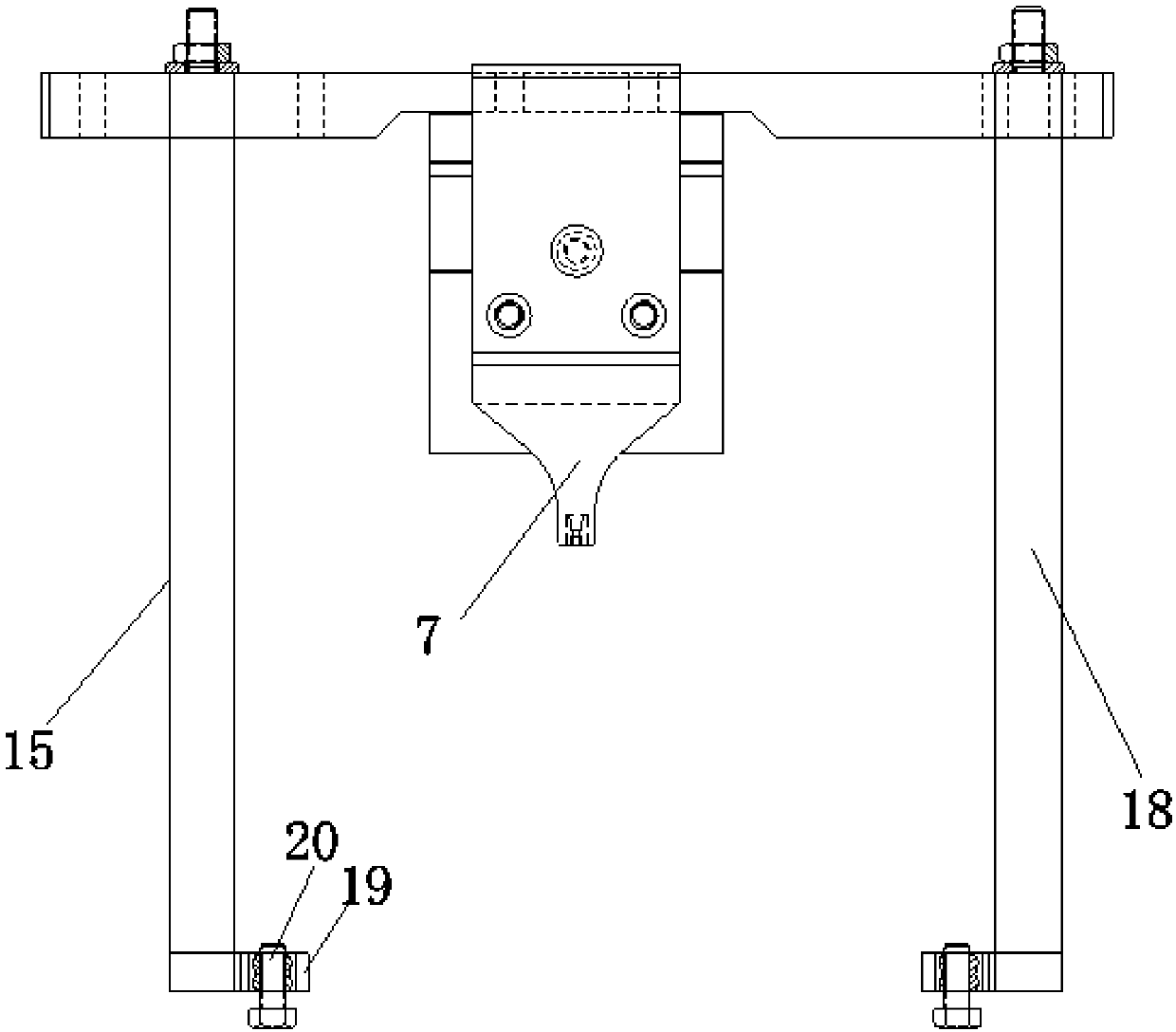

[0022] Refer to attached figure 1 and figure 2 A main reducer locknut slotted pressure pliers shown includes a clamp holder 1 and a positioning rod holder 2 arranged on the clamp holder 1; the two clamp holders 1 Two handles 5 are symmetrically arranged on the fixed plate 3 and the oil cylinder baffle 4, which is convenient for workers to move by hand; , easy to lift.

[0023] The fixed plate 3 and the oil cylinder baffle 4 are fixed on the clamping pliers fixing seat 1 through a taper pin, the fixed clamping pliers 7 are installed on the fixed plate 3, the oil cylinder 9 is installed on the oil cylinder baffle plate 4, and the fixed clamping pliers 7 and the oil cylinder 9 are opposite to each other. Set, the piston rod 91 end of the oil cylinder 9 is vertically directed to the fixed clamp 7, and the slide clamp 8 is fixed on the piston rod 91.

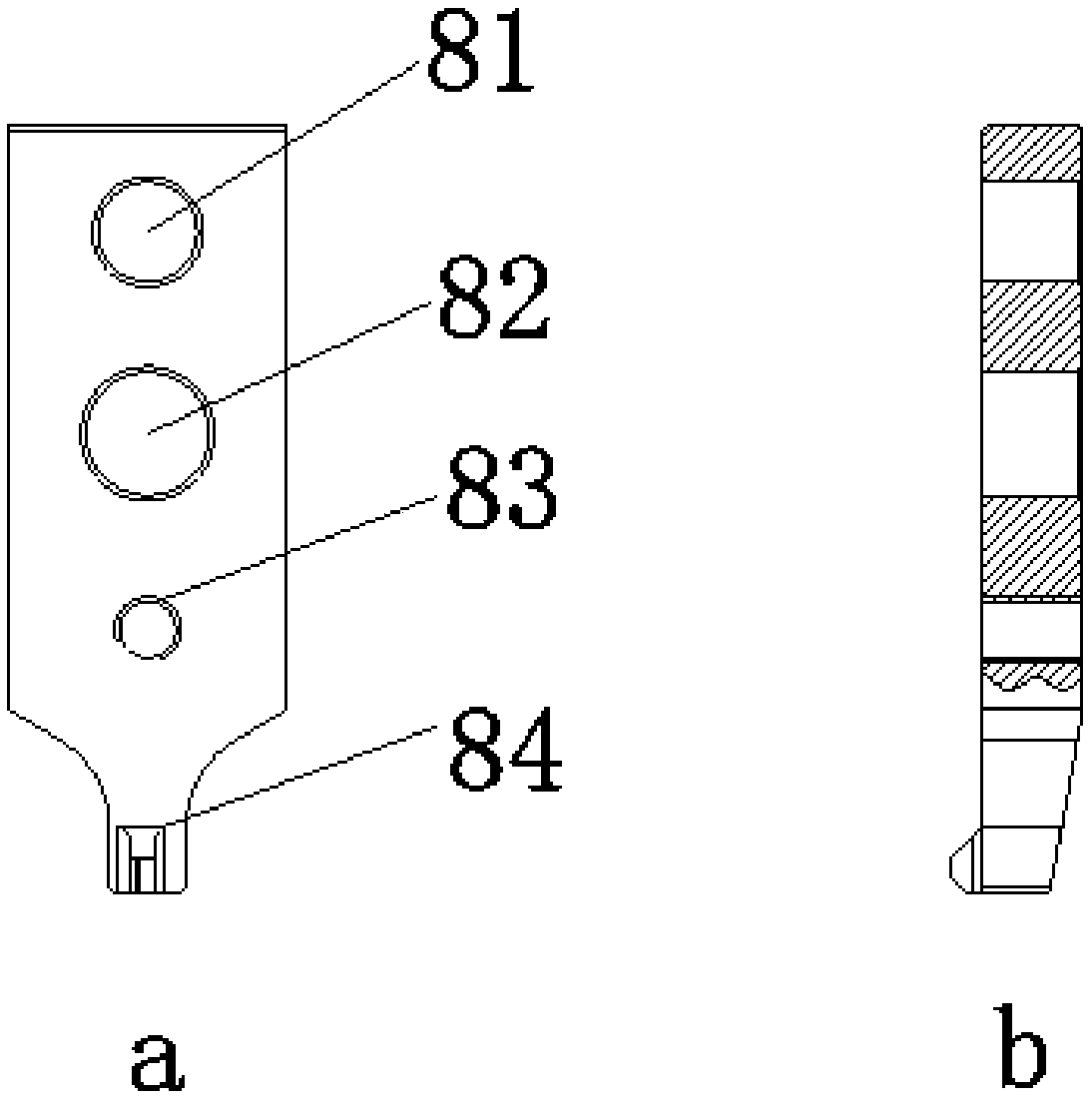

[0024] refer to Figure 4 and Figure 5 As shown, the guide rod installation hole 81, the piston rod installation hole 82 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com