Woodworking sliding table saw capable of being adjusted conveniently and rapidly

A technology for pushing table saws and woodworking, used in wood processing appliances, circular saws, sawing components, etc., can solve problems such as inability to adjust, poor wood cutting quality, and unstable clamping, to ensure cutting accuracy and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

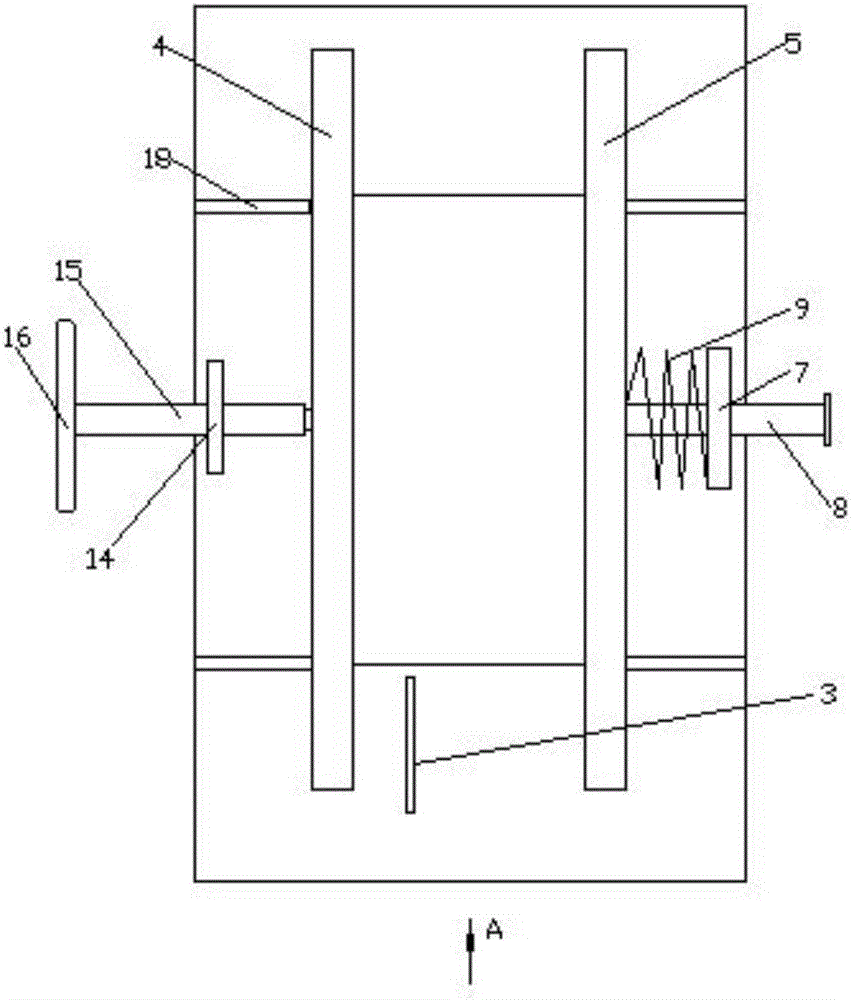

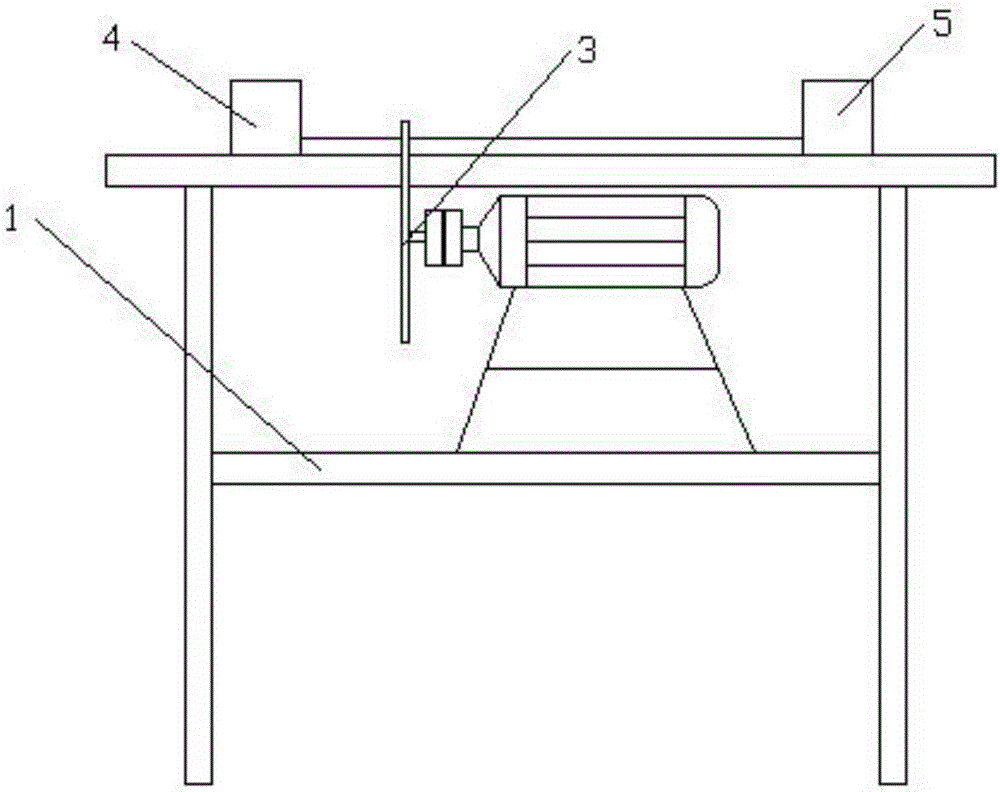

[0013] figure 1 and figure 2 A schematic structural view of a conveniently adjustable woodworking table saw provided by the present invention is shown, which is characterized in that it includes a table frame 1 and a saw blade 3 located on the table frame 1, and the two saw blades 3 Side sliding is provided with left push pedal 4 and right push pedal 5, and left push pedal 4 and right push pedal 5 slide along the width direction of push platform frame 1 and plank is placed between left push pedal 4 and right push pedal 5; The sliding direction of right push pedal 5 is provided with stop block 7, and stop block 7 is positioned at the right side of right push pedal 5, and sliding bar 8 is provided with on stop block 7, and slide bar 8 is fixedly connected with the side of right push plate 5 and slides. A spring 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com