Board pressing device

A pressing device and wood board technology, which is applied in the field of wood processing, can solve the problems of poor cylinder stroke accuracy and unsatisfactory board pressure effect, etc., and achieve the effect of good pressing effect, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

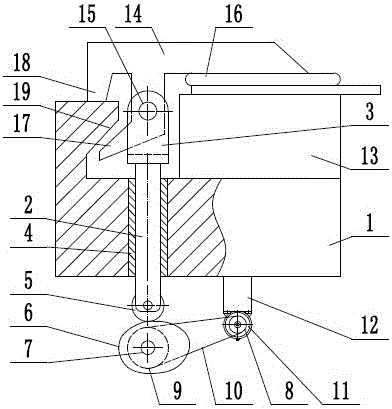

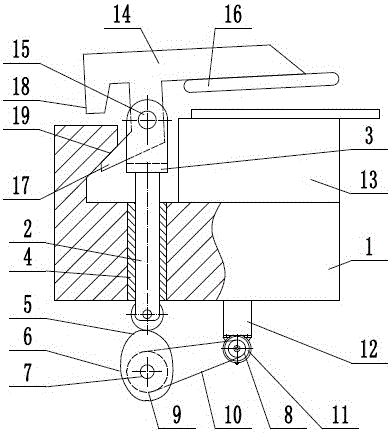

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0013] like figure 1 and figure 2 Shown, a kind of plank pressing device, it comprises fixture supporting seat 1, pull rod 2, connecting lug 3, sliding sleeve 4, supporting roller 5, cam 6, supporting shaft 7, first pulley 8, second pulley 9, Drive belt 10, drive motor 11, motor support 12, work platform 13, T-shaped support 14, bearing pin 15, pressing plate 16, described pull bar 2 can slide up and down and be arranged on the clamp support seat 1, described pull bar 2 and clamp A sliding sleeve 4 is arranged between the support bases 1, which reduces the wear between the pull rod 2 and the fixture support base 1, and greatly improves the service life of the pull rod 2. The support roller 5 is rotatably arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com