Resistor inversion conversion tooling and resistor inversion conversion method

A technology for resistors and inversion, which is applied in the field of inversion conversion tooling, which can solve the problems of fragile lead wires of resistors, difficulty in inversion, and low product yield, so as to reduce damage rate, improve quality and yield, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

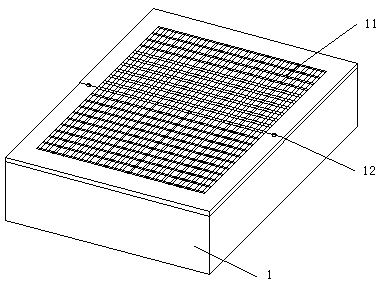

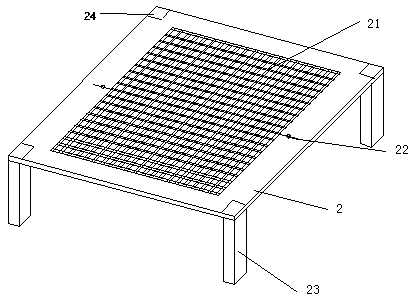

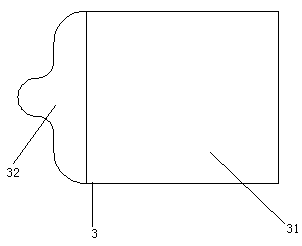

[0023] see Figure 1 to Figure 5 , showing various devices used in the resistor inversion conversion tooling of the present invention. figure 1 is bottom mold 1, figure 2 It is the middle model 2. The so-called inverted mold conversion is to flip the batch resistors originally in the first bottom mold to another second bottom mold without resistors, so as to realize the transfer and flip of the resistors. Both the upper surface of the bottom mold and the middle mold have a grid area and a non-grid area. The non-grid area surrounds the grid area. The grid area contains a plurality of grids, and gaps are formed between the grids. The gap between the grids 21 can pass through the resistor, and the gap between the grids of the bottom mold 11 is a structure in which the aperture decreases from top to bottom, so that the chip body of the resistor can be stuck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com