Assembling type water tank side plate base plate without transverse seams

A non-horizontal, assembly-type technology, applied in packaging, transportation, packaging, containers, etc., can solve the problems of poor sealing effect at the intersection of horizontal seams and vertical seams, washing away surrounding objects or people, weak earthquake resistance of water tanks, etc. , to achieve the effect of improving the anti-seismic effect, increasing the compressive capacity, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

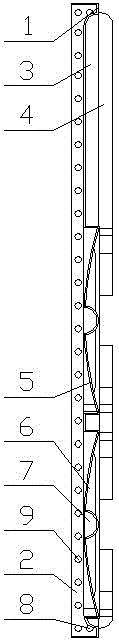

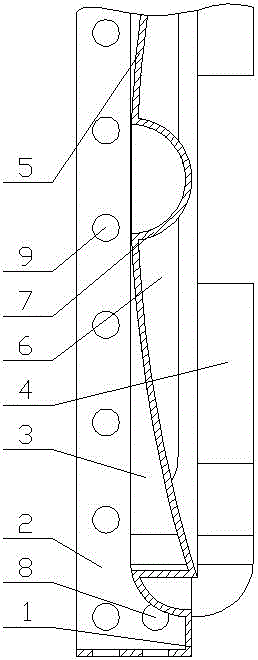

[0036]When the present invention is in use, the board body 1 is connected and fixed in turn to each side plate of the siege water tank, and the reinforcement rod A10 of the board body 1 is horizontally fixed on the outer surface of the board body 1 through the reinforcement rod connecting hole 9 at the side of the board body 1; There are multiple reinforcing rods A10 fixed, and the distances between two adjacent reinforcing rods A10 are equal;

Embodiment 2

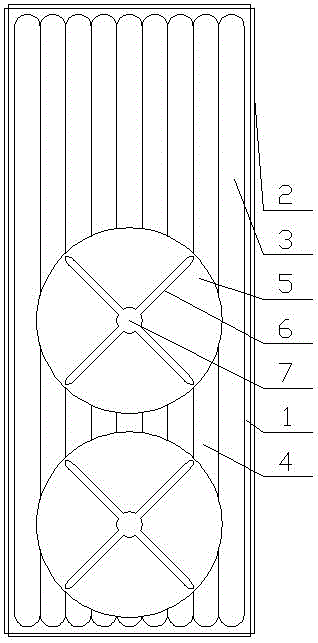

[0038] When the present invention is used, the board body 1 is sequentially connected and fixed to the side panels of the siege water tank, and the reinforcing rod B11 of the board body 1 is obliquely fixed on the outer surface of the board body 1 through the reinforcing rod connecting hole 9 at the side of the board body 1; The reinforcement rods B11 are fixed in multiples and are parallel to each other. The reinforcement rods C12 and the reinforcement rods B11 are intersected. It is fixed with the reinforcement rod B11, and the reinforcement rod B11 and the reinforcement rod C12 form a reinforcement rod combination with an "X" shape structure, and the distances between two adjacent reinforcement rod combinations are respectively equal; the reinforcement on two adjacent boards 1 The fixing position of the rod combination and the flange 2 on the side of the plate body 1 is the same.

Embodiment 3

[0040] When the present invention is in use, the plate body 1 is connected and fixed in turn to each side plate of the siege water tank, and the reinforcing rod D13 of the plate body 1 is horizontally fixed on the outer surface of the plate body 1 through the reinforcing rod connecting hole 9 at the side of the plate body 1; There are multiple reinforcing rods D13 fixed, the reinforcing rods E14 and the reinforcing rods D13 are intersected, one end of the reinforcing rod E14 is fixed to the reinforcing rod connecting hole 9 on the flange 2 of the side of the plate body 1, and the other end is connected to the reinforcing rod D13 is fixed, and the reinforcement rod D13 and the reinforcement rod E14 form a reinforcement rod combination with a "Ж" shape structure, and the distances between the adjacent two reinforcement rod combinations are respectively equal; the reinforcement rod combinations on the adjacent two boards 1 and The fixing positions of the flanges 2 on the sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com