Manufacturing and mounting method of assembly and decoration integrated wall for industrial building

A technology for industrial buildings and buildings, applied in the processing of building materials, construction, building components, etc., can solve the problems of poor thermal insulation uniformity, wall air tightness, increased use of wall purlins, increased material consumption, etc., to achieve beneficial The effect of construction quality control, simplified installation method, and improved seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

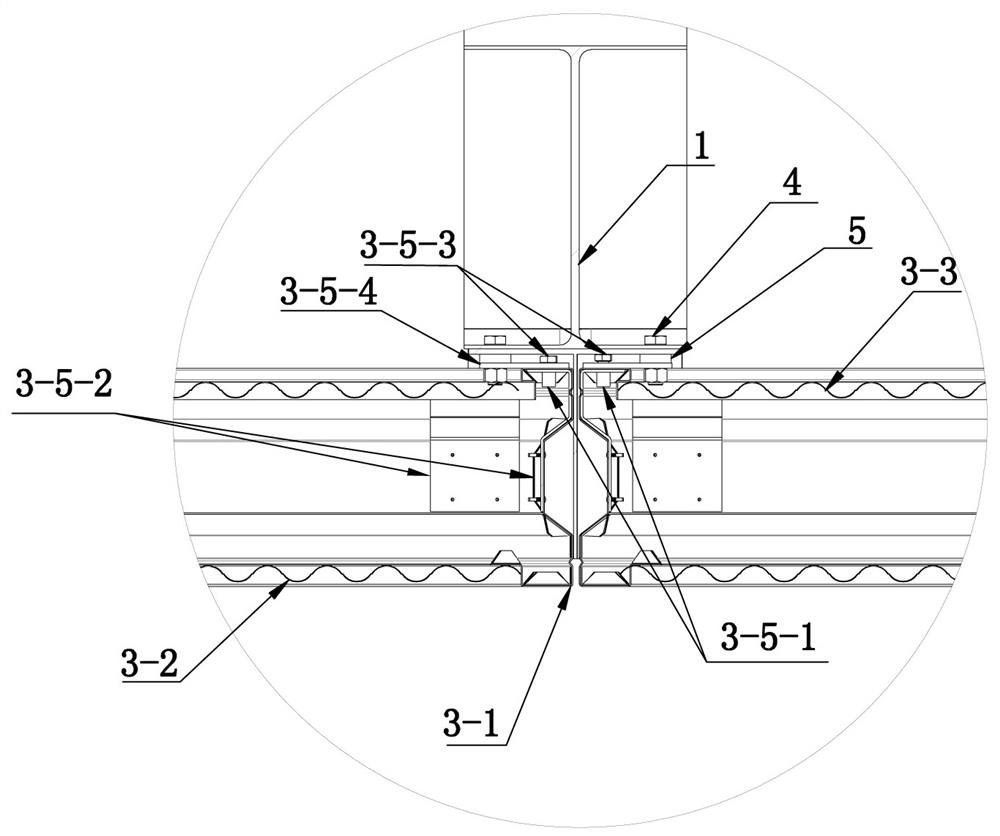

[0030] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

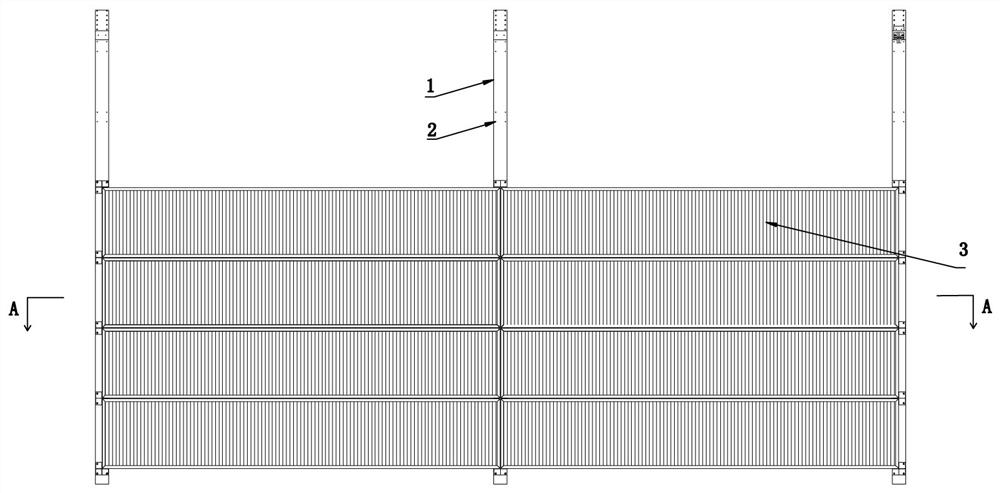

[0031] Such as Figure 1-9 As shown, the manufacturing and installation method of the assembly and decoration integrated wall for industrial buildings of the present invention is characterized in that it comprises the following steps:

[0032] (1) Factory-manufactured integrated wall with assembly and decoration for industrial buildings

[0033] The main process is: making and forming the frame of the wall structure→installing the structural components→installing the inner decorative panel structure→filling and installing the insulation layer→installing the outer decorative panel structure→installing the structural components and installing→packaging the finished product;

[0034] (2) Integrated wall installation of assembly and decoration for industrial buildings

[0035] The main construction process is: steel structure column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com