mems microphone chip and manufacturing method thereof

A manufacturing method and microphone technology, which are applied to sensors, electrostatic transducers, microphones, electrical components, etc., can solve the problems of increasing the cutting cost of MEMS chip units, difficulty in etching the substrate thickness, and being unsuitable for mass production. The effect of easy process, improved yield and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

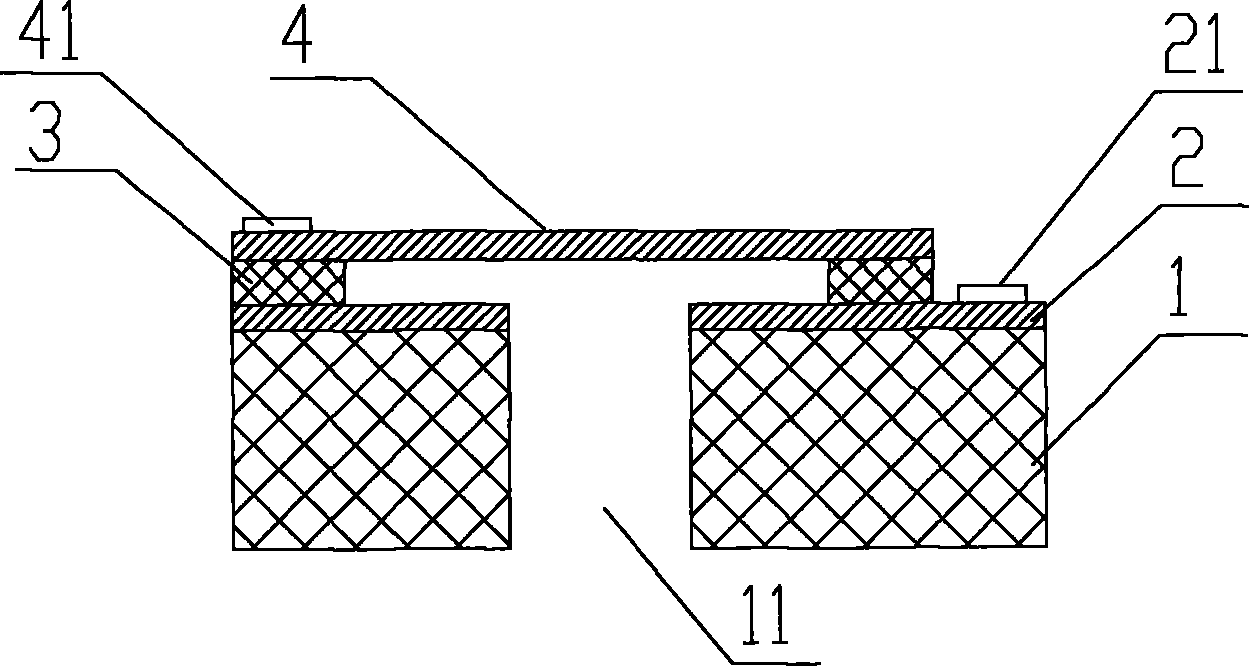

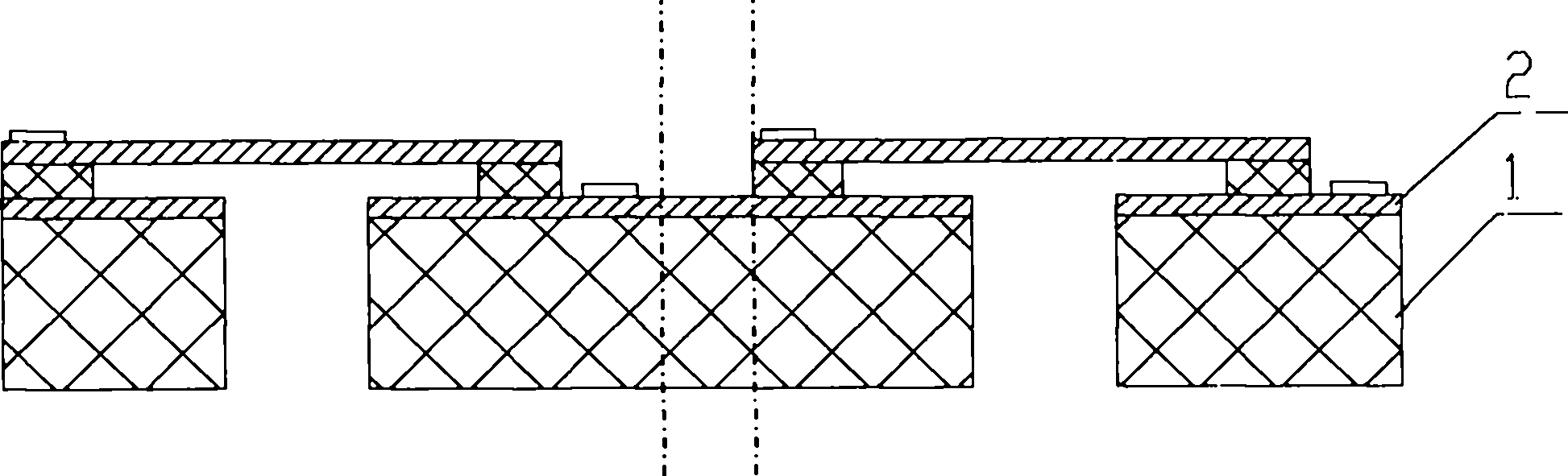

[0035] image 3 It is a configuration diagram showing the MEMS microphone chip according to the first embodiment of the present invention. Such as image 3 As shown, the MEMS microphone chip includes a base 1, the base 1 is provided with a hole 11 through up and down, and a parallel plate capacitor composed of a fixed plate 2, an isolation layer 3 and a vibrating membrane 4 is provided above the base, in the parallel plate capacitor The vibrating membrane 4 can receive external sound signals from above or below and vibrate, so that the parallel plate capacitor generates an electric signal to realize the sound-to-electricity conversion function. A metal connection point 21 is arranged on the fixed pole plate 2, and a metal connection point 41 is arranged on the vibrating membrane 4, and the connection points 21 and 41 can lead out two electrodes of the parallel plate capacitor respectively. Moreover, a protection device 5 is provided on the side of the parallel plate capacito...

no. 2 example

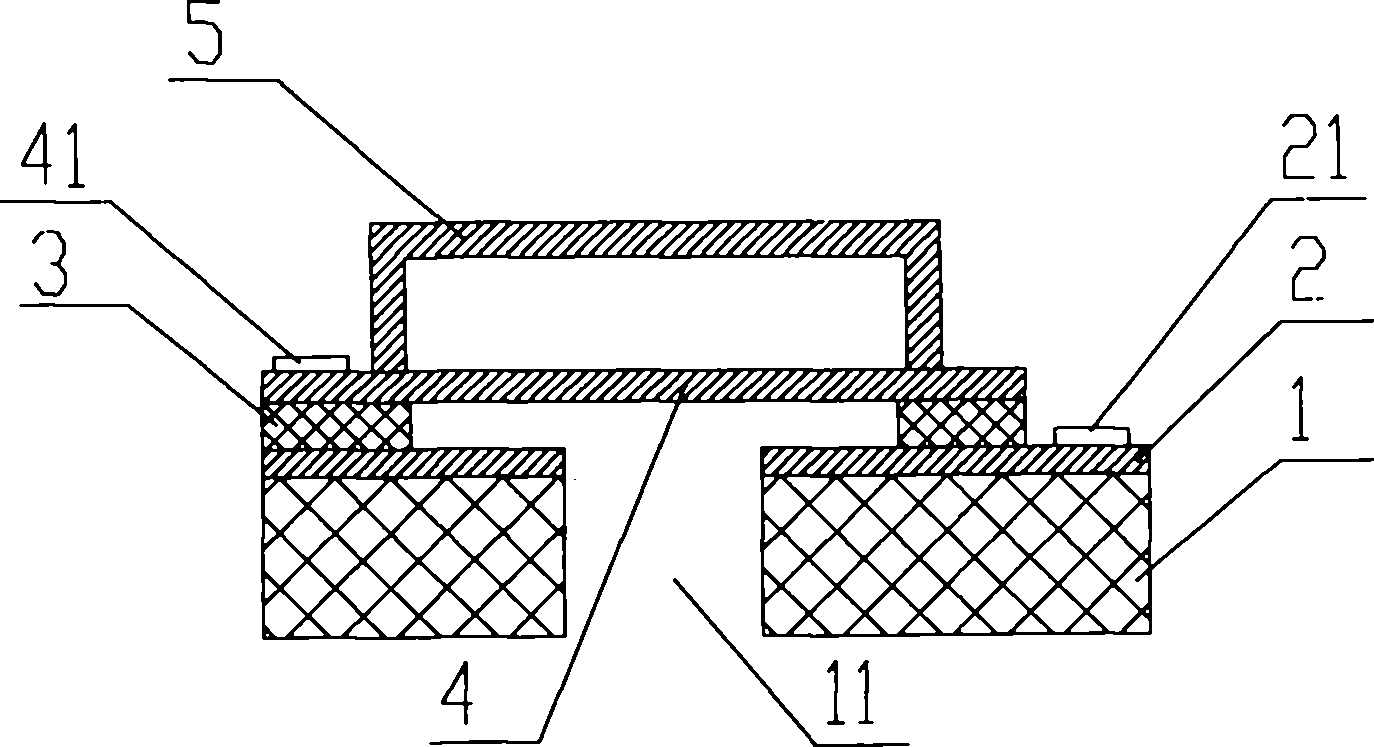

[0048] Image 6 It is a configuration diagram showing the MEMS microphone chip according to the second embodiment of the present invention. Such as Image 6 As shown, the MEMS microphone chip includes a base 1, the base 1 is provided with a hole 11 through up and down, and a parallel plate capacitor composed of a fixed plate 2, an isolation layer 3 and a vibrating membrane 4 is arranged above the base, and the fixed plate 2 A metal connection point 21 and a metal connection point 41 for leading out the two electrodes of the parallel plate capacitor are respectively arranged on the vibrating film 4, and are arranged on the side opposite to the substrate 1 of the parallel plate capacitor and above the vibrating film 4 There is a protection device 5, which is used to separate structures such as relatively fragile vibrating membranes in the parallel plate capacitor from the external space of the MEMS microphone chip, so as to prevent the MEMS microphone chip from being polluted d...

no. 3 example

[0051] Figure 7 is a configuration diagram showing a MEMS microphone chip according to a third embodiment of the present invention. Such as Figure 7 As shown, the MEMS microphone chip includes a base 1, the base 1 is provided with a hole 11 through up and down, and a parallel plate capacitor composed of a fixed plate 2, an isolation layer 3 and a vibrating membrane 4 is arranged above the base, and the fixed plate 2 A metal connection point 21 and a metal connection point 41 for leading out the two electrodes of the parallel plate capacitor are respectively arranged on the vibrating film 4, and are arranged on the side opposite to the substrate 1 of the parallel plate capacitor and above the vibrating film 4 There is an annular support ring 52 and a flat plate 53 . The annular support ring 52 and the flat plate 53 and the diaphragm form a protective structure capable of sealing the diaphragm 4, which is used to separate the relatively fragile diaphragm and other structures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com