Manufacturing method of pneumatic tire

一种充气轮胎、制造方法的技术,应用在胎、家里用具、其他家里用具等方向,能够解决轮胎外观变差、成型不良等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

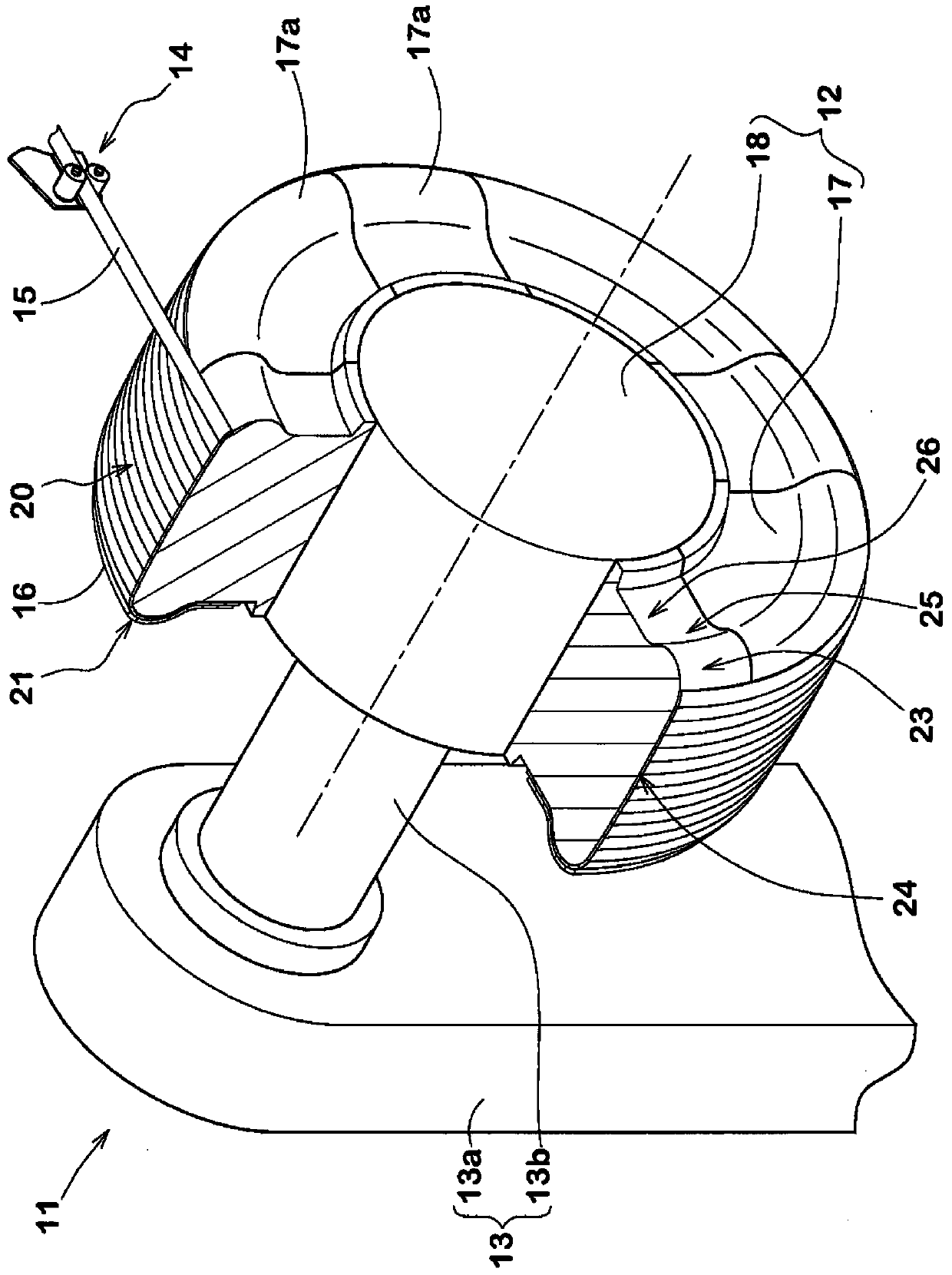

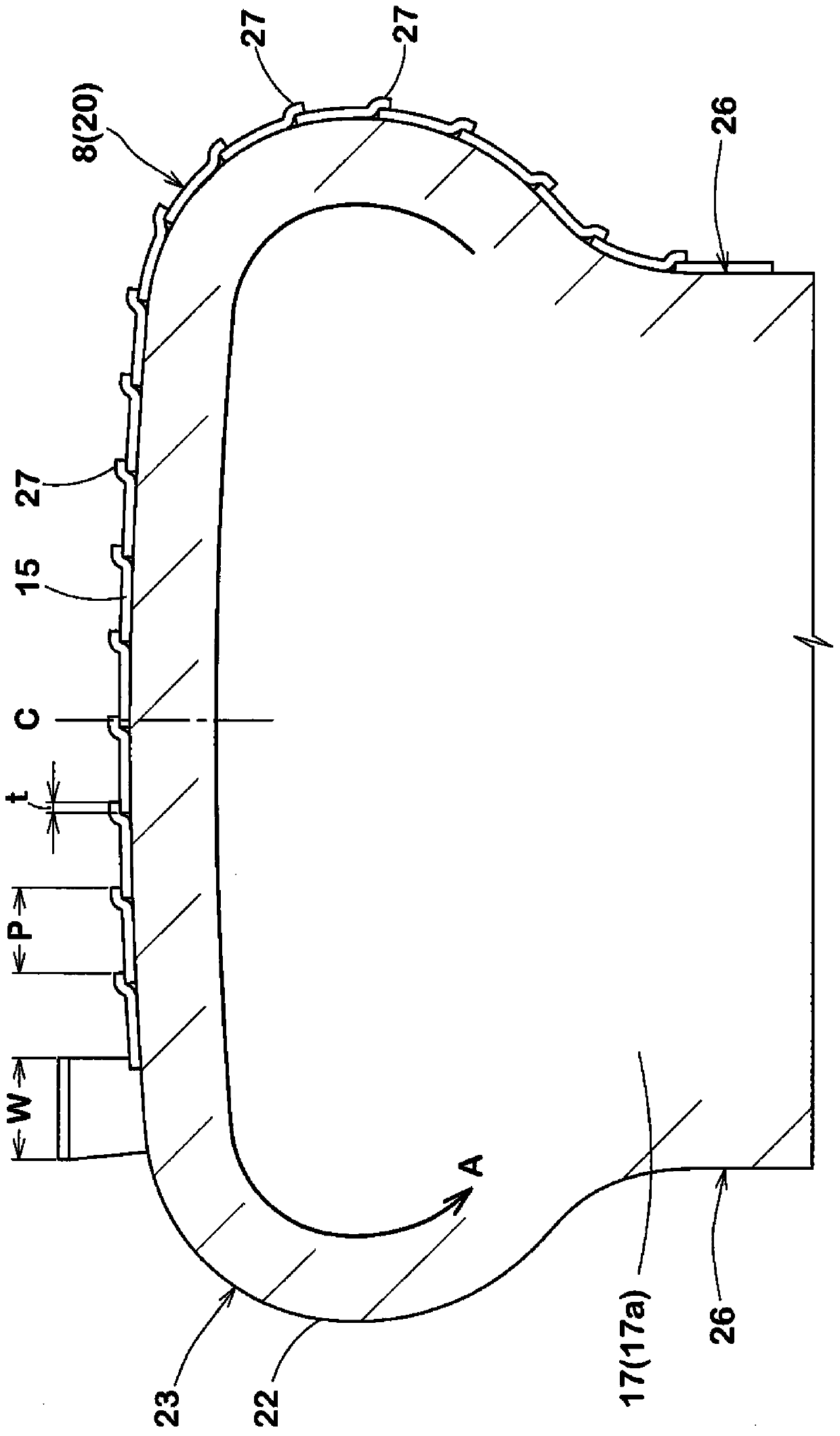

[0022] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

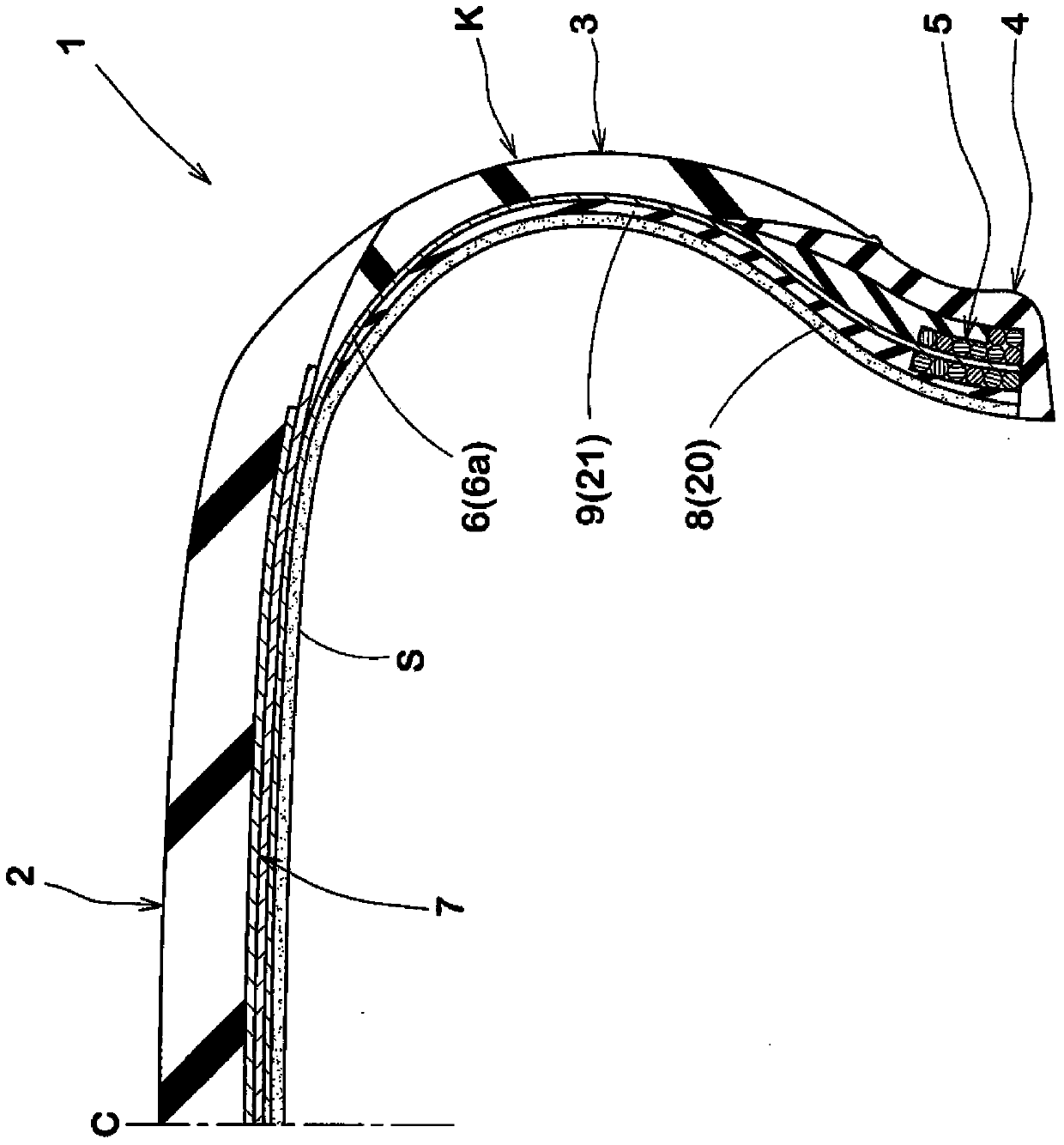

[0023] figure 1 2 shows a meridian cross-sectional view of the right half of a pneumatic tire (hereinafter, sometimes simply referred to as "tire") 1 manufactured by the method for manufacturing a pneumatic tire of the present invention. The pneumatic tire 1 of the present embodiment can be preferably used as a passenger car, for example.

[0024] The tire 1 includes: a carcass 6 having a carcass ply 6 a extending from a tread portion 2 via a sidewall portion 3 to a bead core 5 of a bead portion 4 ; The inner liner layer 8 is arranged on the inner side of the carcass 6 to form the inner cavity surface S of the tire; and the isolation (insulation) layer 9 is arranged on the carcass 6 and the inner liner layer. between 8. The barrier layer 9 of the present embodiment is arranged only on the tire side surfaces K on both sides, and is not provided on the tread portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com