Heating type heat preservation barrel

A heat preservation barrel and heating technology, which is applied in food heating containers, packaged foods, containers, etc., can solve the problems of short heat preservation time and poor heat preservation effect, and achieve the effect of long heat preservation time, good heat preservation effect, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

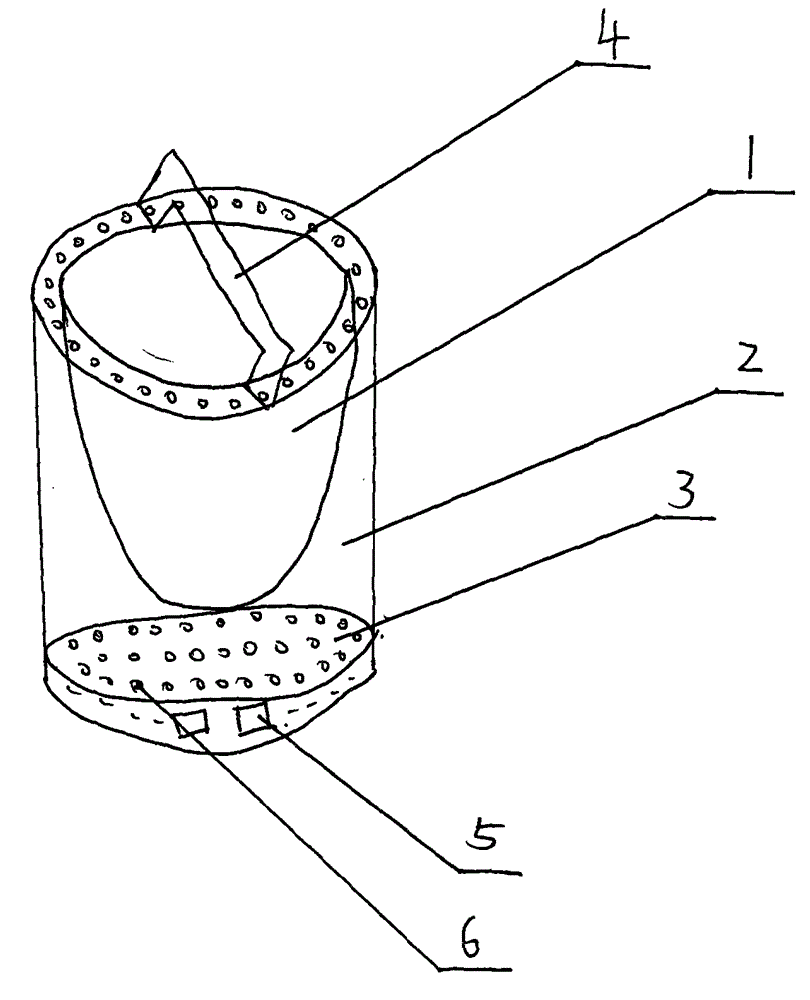

[0014] A heating type heat preservation barrel is composed of an inner barrel (1), an outer barrel (2), a partition (3), a handle (4), a heating bag (5), and an air outlet (6). The clapboard (3) is located at the bottom of the outer barrel (2), the inner barrel (1) is located on the clapboard (3), and many air outlet holes (6) are evenly distributed on the clapboard (3), and the periphery of the inner barrel (1) is also distributed With a circle of air outlets (6), the handle (4) is installed on the outer barrel (2).

[0015] When working: put food into the inner barrel (1), put the heating package (5) into the outer barrel (2), add water, place the partition (3) on the bottom of the outer barrel (2), and place the inner barrel (1) on the partition On the board (3), cover the bung, handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com