Feeding device for water-absorbent resin semi-finished product

A technology of feeding device and water-absorbing resin, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of unsafety, dampness of raw materials, unreliability, etc., and achieve the effect of scientific design, convenient movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

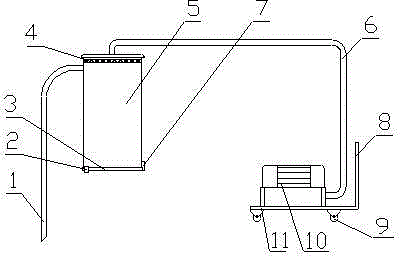

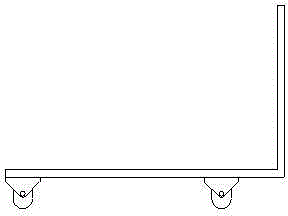

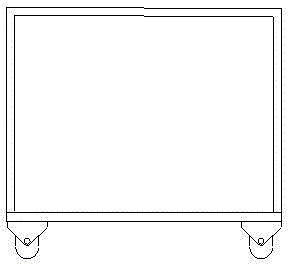

[0017] like figure 1 , figure 2 and image 3 As shown, a water-absorbing resin semi-finished product feeding device of the present invention includes a suction pipe 1, a suction box 5, an air suction pipe 6, a vacuum pump 10 and a dolly 11, the vacuum pump 10 is placed on the dolly 11, and the dolly 11 Set four universal wheels 9 and a car handrail 8, the vacuum pump 10 is connected to one end of the suction pipe 6, the top of the suction box 5 is connected to the other end of the suction pipe 6, and the upper end of the suction box 5 is connected to the suction pipe 1. The lower end of the suction box 5 is provided with a discharge door 3, the discharge valve 2 and the door handle 7 are arranged on the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com