Full-automatic centre for take-up and pay-off stands of optical cable stranding machines

A twisting machine, winding and unwinding technology, applied in the field of fully automatic top, can solve the problems of prolonging the production time of optical cables, reducing the production efficiency, and difficult for operators, and achieving the advantages of reducing the operation time of changing the disc, improving the production efficiency and accurate detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in detail:

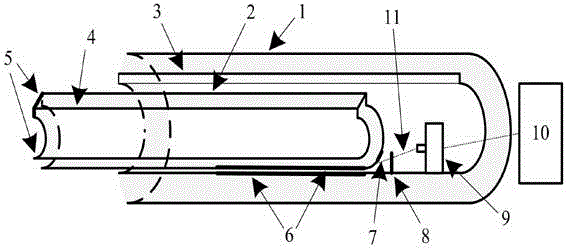

[0012] Such as figure 1 As shown in the figure, a fully automatic top for the take-up and release rack of an optical cable stranding machine includes a top 1, and the top 1 contains a solid disk bearing 2, a solid-slip groove 3, a solid-slip convex groove 4, and a front pressure Sensor 5, gear guide rail 6, post-stage pressure sensor 7, shrink cut-off line 8, retractable motor 9, motor controller 10 and wire 11.

[0013] The top 1 adopts a stainless steel cylindrical structure and is installed on each take-up and release rack of the optical cable stranding machine. The inner layer is designed as a cylindrical hollow with a diameter of 0.82 meters and a wall thickness of 0.06 meters. The top of the inner layer contains a solid-slip groove 3. The bottom end contains a 0.06-meter-long gear guide rail 6 and a shrinkage cut-off line 8, and is fixed with a retractable motor 9; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com