Missile loaded vehicle hoisting mechanism based on guide rod mechanism and parallelogram mechanism

A parallelogram and hoisting mechanism technology, applied in the direction of equipment for transporting goods, lifting frames, lifting devices, etc., can solve the problems of large load, less manpower demand, good control accuracy, etc., to achieve low cost and less manpower required. , the effect of effective and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

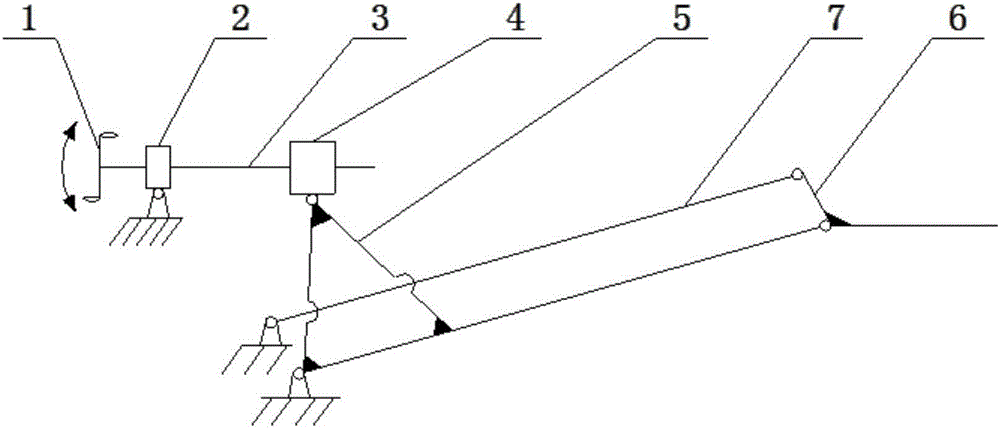

[0029] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0030] A lifting mechanism for a bomb trailer based on a guide rod and a parallelogram mechanism. pole 7;

[0031] The handle 1 is connected to the lead screw 3 through threads;

[0032] Nut one 2 is connected to the lead screw 3 through thread transmission, and nut two 4 is connected to the lead screw 3 through thread transmission;

[0033] Nut one 2, lead screw 3, nut two 4, connecting arm 5 form a guide rod mechanism, connecting arm 5, tray 6, and holding rod 7 form a parallelogram mechanism;

[0034] Nut two 4 are respectively hinged with the respective connecting arms of two groups of parallelogram mechanisms.

[0035] Two sets of parallelogram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com