Omni-directional mobile carrying trolley

A technology for moving and transporting trolleys in all directions, applied in the field of transport robots, can solve the problems of difficult maintenance, high cost of transport vehicles, complex structures, etc., and achieve the effects of easy unloading of goods, simple structure, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

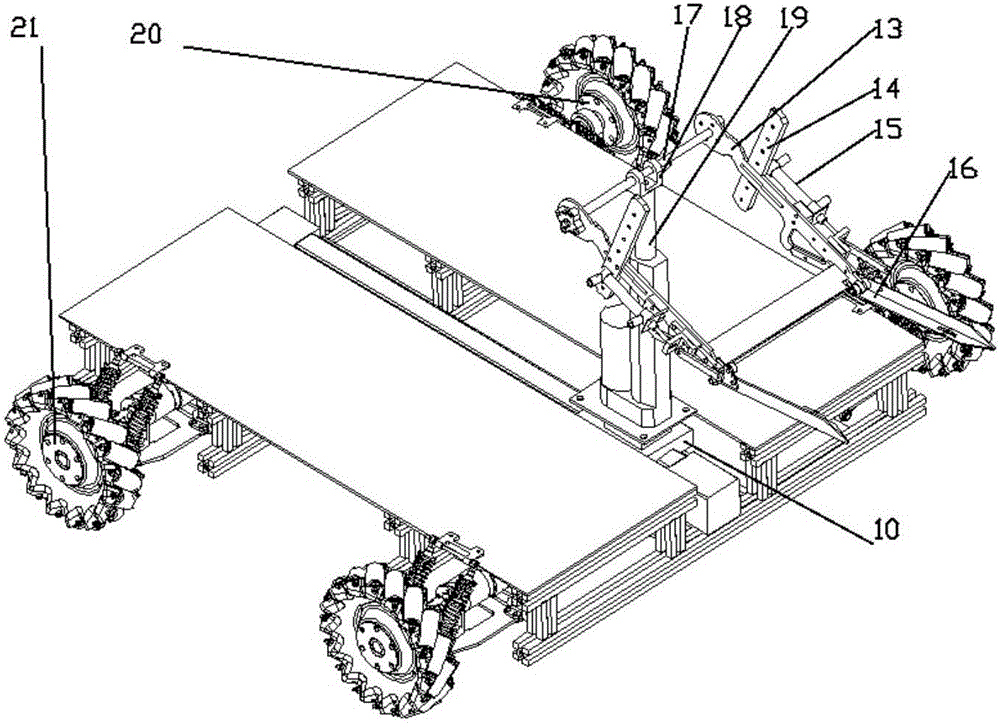

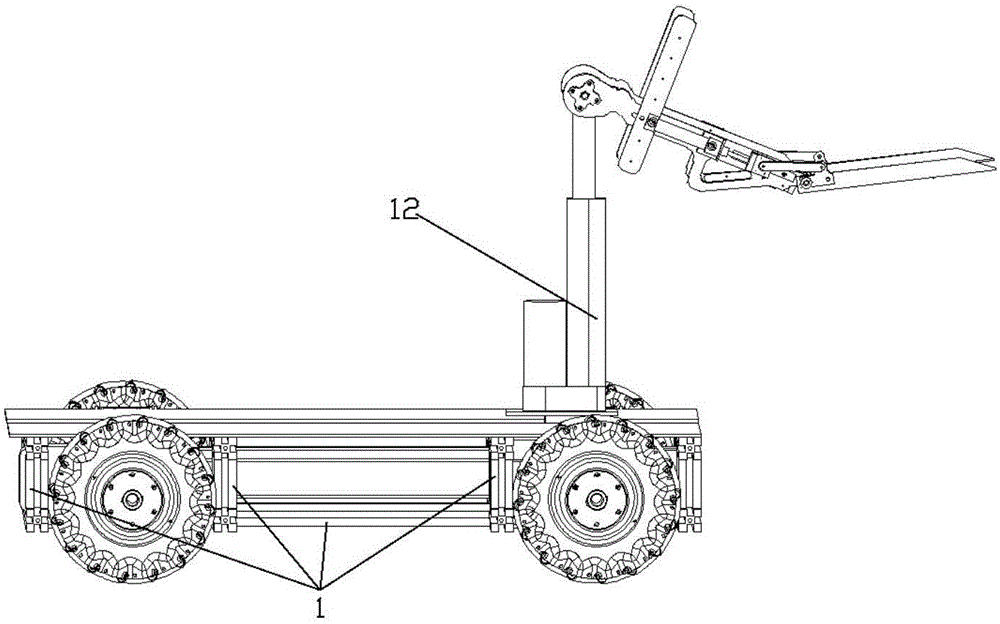

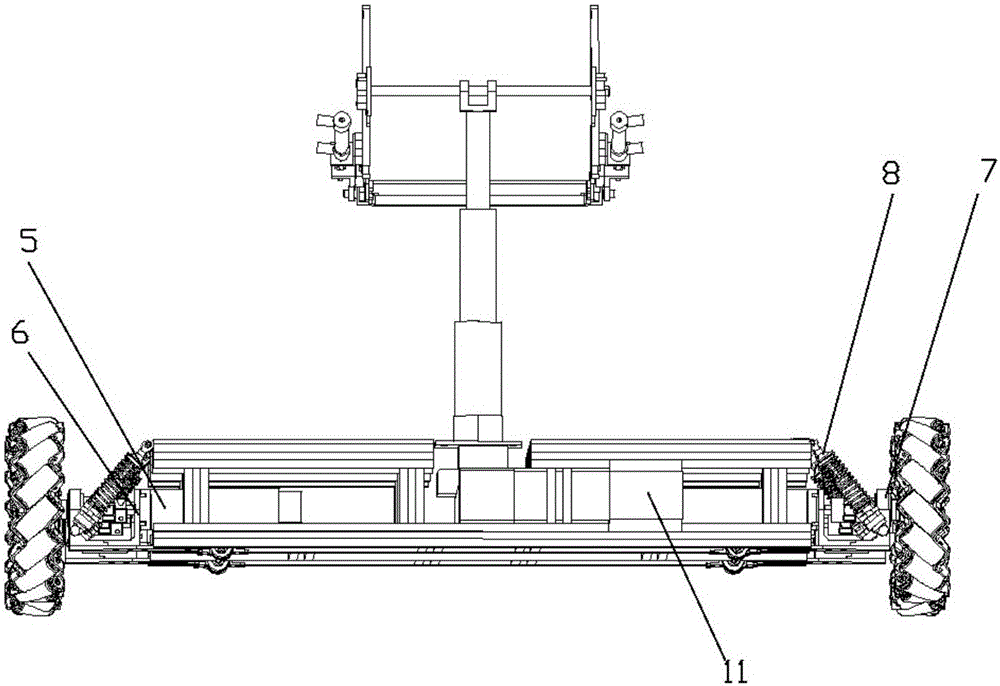

[0024] Such as Figures 1 to 6 Shown is a structural diagram of an embodiment of the present invention, including: skeleton 1, stage 2, mecanum omnidirectional wheel 3, coupling 4, DC motor 5, DC motor support 6, shock-absorbing base 7 , shock absorber 8, ball screw 9, sliding nut 10, ball screw drive motor 11, main electric push rod 12, fixed arm 13, baffle plate 14, auxiliary electric push rod 15, pick-up rack 16, fixed rod 17 , fixed bearing 18, movable bar 19, wheat wheel shaft 20, wheat wheel shaft cover plate 21, auxiliary electric push rod motor bearing 22, slide block 23, slideway 25, connecting rod 25, rotating shaft 26.

[0025] Skeleton 1 is made of aluminum profile, and above the aluminum profile is laid a stage 2 formed by two aluminum plates. Certain electronic components can be placed on stage 2; there are 4 mecanum omnidirectional wheels 3 and 3 mecanu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com