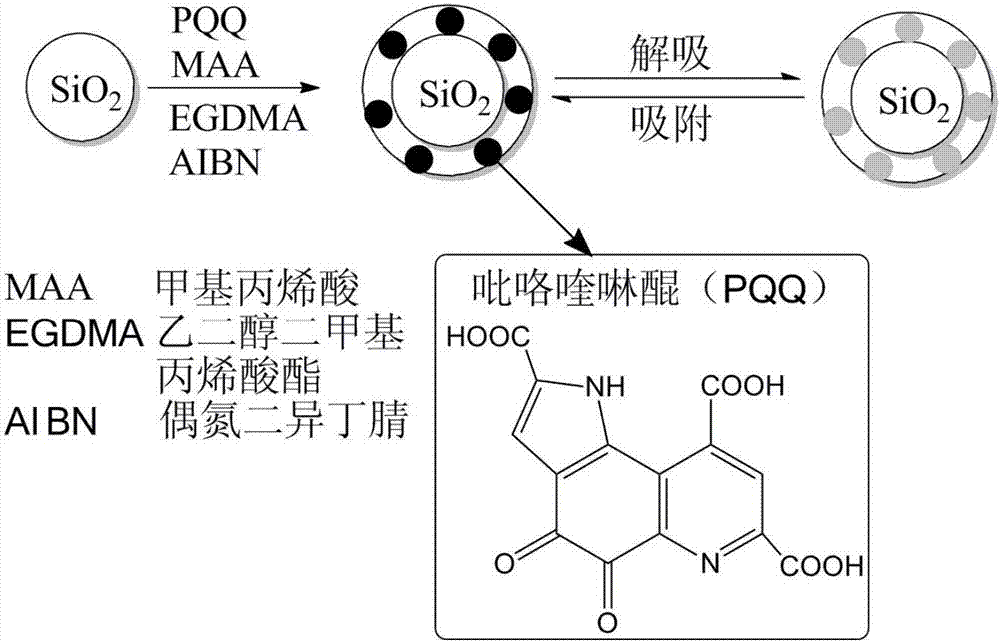

Method for separating and purifying pyrroloquinoline quinone in fermentation broth by molecular imprinted solid phase extraction

A technology of pyrroloquinoline quinone and solid phase extraction, applied in chemical instruments and methods, organic chemistry, other chemical processes, etc., to achieve the effect of facilitating large-scale industrial production, simple process operation, and high-efficiency separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for separating and purifying pyrroloquinoline quinone in fermentation broth by molecular imprinted solid phase extraction, comprising the following steps:

[0041](1) Preparation: Utilize pyrroloquinoline quinone producing bacteria to prepare a fermentation broth containing pyrroloquinoline quinone. The specific method is: inoculate Gluconobacter oxydans in the fermentation medium according to the inoculation amount of 5%, and inoculate the fermentation medium at 28° C. Shake culture for 3 days to obtain seed liquid; then inoculate the seed liquid into enriched medium according to the inoculum amount of 10%, shake culture at 28°C for 5 days, centrifuge the culture liquid at 5°C and 9000r / min for 15min, and collect the supernatant to obtain a fermented liquid rich in pyrroloquinoline quinone whose pyrroloquinoline quinone concentration is 100-200mg / L;

[0042] (2) Extraction and separation: the fermentation broth containing pyrroloquinoline quinone is extracted ...

Embodiment 2

[0048] A method for separating and purifying pyrroloquinoline quinone in fermentation broth by molecular imprinted solid phase extraction, comprising the following steps:

[0049] (1) Preparation: Utilize pyrroloquinoline quinone producing bacteria to prepare a fermentation broth containing pyrroloquinoline quinone. The specific method is: inoculate Gluconobacter oxydans in the fermentation medium according to the inoculation amount of 5%, and inoculate the fermentation medium at 28° C. Shake culture for 3 days to obtain seed liquid; then inoculate the seed liquid into enriched medium according to the inoculum amount of 10%, shake culture at 28°C for 5 days, centrifuge the culture liquid at 5°C and 9000r / min for 15min, and collect the supernatant to obtain a fermented liquid rich in pyrroloquinoline quinone whose pyrroloquinoline quinone concentration is 100-200mg / L;

[0050] (2) Extraction and separation: the fermentation broth containing pyrroloquinoline quinone is extracted...

Embodiment 3

[0056] A method for separating and purifying pyrroloquinoline quinone in fermentation broth by molecular imprinted solid phase extraction, comprising the following steps:

[0057] (1) Preparation: Utilize pyrroloquinoline quinone producing bacteria to prepare a fermentation broth containing pyrroloquinoline quinone. The specific method is: inoculate Gluconobacter oxydans in the fermentation medium according to the inoculation amount of 5%, and inoculate the fermentation medium at 28° C. Shake culture for 3 days to obtain seed liquid; then inoculate the seed liquid into enriched medium according to the inoculum amount of 10%, shake culture at 28°C for 5 days, centrifuge the culture liquid at 5°C and 9000r / min for 15min, and collect the supernatant to obtain a fermented liquid rich in pyrroloquinoline quinone whose pyrroloquinoline quinone concentration is 100-200mg / L;

[0058] (2) Extraction and separation: the fermentation broth containing pyrroloquinoline quinone is extracted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com