Dendritic fiber filament and forming device

A molding device and fiber filament technology, which is applied in the field of fiber filament manufacturing, can solve problems such as the inability to realize silk surface spraying, and achieve the effects of strong hand feeling, elastic and soft hand feeling, and good warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

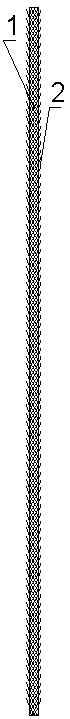

[0012] Embodiment 1: with reference to attached figure 1 . A kind of dendritic fiber thread, the thread surface of the fiber thread 1 is distributed with warped branch thread surfaces 2 at unequal intervals. The surface of the branch silk surface 2 is a knife-peeled and turned-out surface. The fiber filaments refer to chemical fibers, including polyester filaments, DTY stretched filaments, and FDY colored filaments, but are not limited thereto.

Embodiment 2

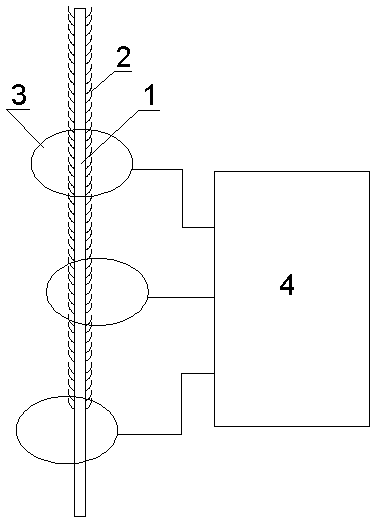

[0013] Embodiment 2: with reference to attached figure 2 and 3 . A dendritic filament forming device, a plurality of knife rings 3 with equal diameters are dislocated from top to bottom, and the plurality of knife rings 3 are slightly moved left and right or front and back driven by an external force device 4. The external force device refers to a pneumatic drive device Or electric drives or magnetic drives. The frequency of fretting is 5-50 times per second. The blade in the knife ring is inclined downward and the depth of the blade is 1 / 4 to 1 / 3 of the diameter of the fiber filament and a plurality of knife rings 3 with equal diameters are dislocated from top to bottom and the distance is less than 1 / 2 of the diameter of the knife ring. To avoid damage to the fiber filaments.

Embodiment 3

[0014] Embodiment 3: On the basis of embodiment 1 and 2, a kind of forming method of dendritic fiber filament, when fiber filament 1 passes through dendritic filament forming device from bottom to top, a plurality of knives in the fiber filament forming device The ring 3 is slightly moved left and right or front and back under the drive of the external force device, forcing multiple knife rings 3 to contact with the fiber filaments instantaneously, and the blades in the knife rings 3 strip off the warped branch silk surface 2, so that the fiber silk surface has a dendritic shape Peel the outside with a knife, then heat and shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com