modular house structure

An assembled and modular technology, applied in the direction of building structure, construction, etc., can solve the problems of bearing beam length and high frame lifting, and achieve the effect of small on-site construction amount, high production degree and low steel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

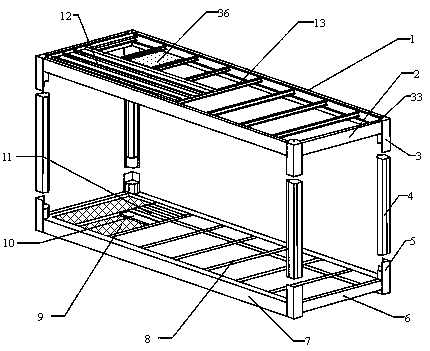

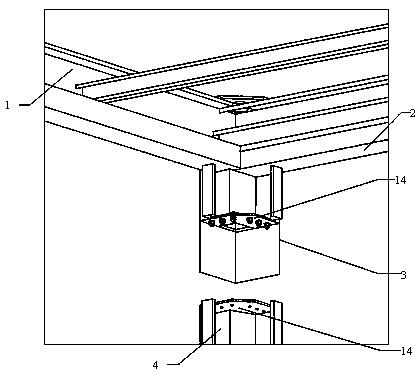

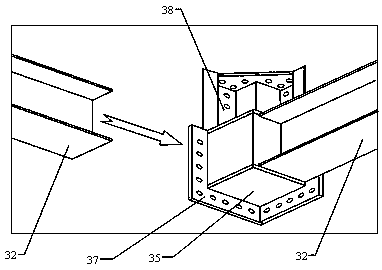

[0027] Combine below Figure 1 to Figure 11 Describe the specific structure and assembly process of a modular assembly type house structure proposed by the present invention.

[0028] Such as figure 1As shown, each small unit of the modular prefabricated house structure includes a roof frame, a ground frame and 4 combined columns (4). Columns (3), roof girders (1), roof beams (2), purlins (13), roof metal plates (12), ceiling perforated sound-absorbing panels (36), hoisting holes (33) are arranged on the roof frame, and the roof The crossbeam (2) doubles as a gutter, the ground frame is also rectangular, and each of the four corners is provided with a downward connecting short column (5) facing upwards. The lower surface of the ground frame is placed on a flat concrete floor, and the ground frame A foundation main beam (7), a foundation beam (6), a floor keel (8), a steel wire mesh (9), a thermal insulation board (10) and a floor (11) are arranged on the top.

[0029] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com