Inflatable skeleton filling wall

An inflatable skeleton and infill wall technology, which is applied to walls, building components, buildings, etc., can solve the problems of increased cost of the main structure, low strength of the infill wall, complicated construction process, etc., and achieves comprehensive cost reduction. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

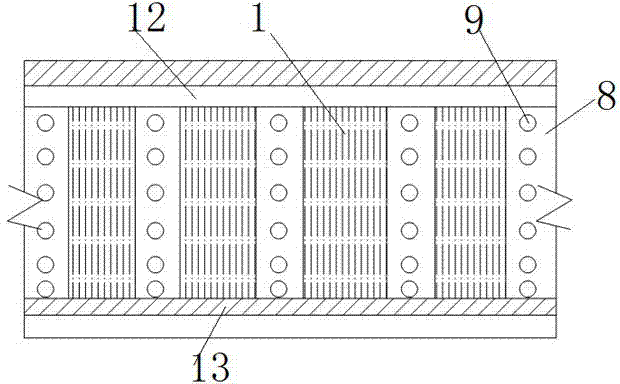

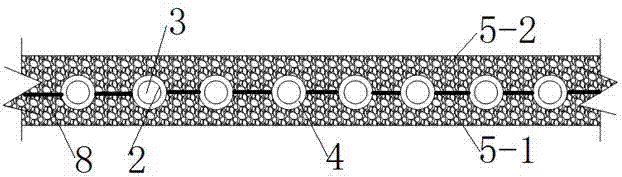

[0029] Such as Figure 12 and image 3 As shown, the cross-section is a single circular inflatable skeleton 1 (hollow columnar film 2 with a vertical length of 2900mm and a diameter of 120mm). After being filled with compressed air at the construction site and formed, fill the central axis of the wall with a middle distance of 150mm (that is, an interval of 30mm). Arrange horizontally in the plane, use expansion bolts to fix the upper and lower ends on the beam 12 and floor 13, use a spraying machine to spray phosphogypsum slurry on the surface of the hollow columnar film 2 with a thickness of 5mm, and after 6 minutes, the phosphogypsum slurry solidifies to make the inflatable skeleton 1 Curing has strength and bearing capacity. Then, use a spraying machine to spray phosphogypsum slurry on the gap between the inflatable skeleton 1 to fill it up and level up to form vertical ribs 6, and then use gypsum mortar (phosphogypsum: fine The sand is prepared according to the volume ra...

Embodiment 2

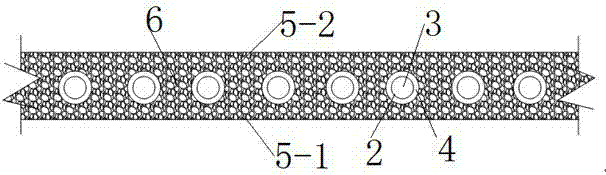

[0031] Such as Figure 5 As shown, the section of the inflatable skeleton 1 is five tangentially connected circles (the vertical length of the hollow columnar film 2 is 2900mm, the diameter of a single circular section is 120mm, and the 5 circles are tangentially connected), and it is formed by filling compressed air at the construction site. Then arrange them in the plane of the central axis of the filling wall according to the middle distance of 750mm (that is, at an interval of 30mm), and the rest are the same as in Embodiment 1. This example can be used for partition walls and general interior partition walls.

Embodiment 3

[0033] Such as Figure 6 As shown, the section of the inflatable skeleton 1 is five intersecting circles (the vertical length of the hollow columnar film 2 is 2900 mm, the diameter of a single circular section is 120 mm, and the five circles are intersecting). Arrange in the plane of the central axis of the filling wall according to the middle distance of 750mm (that is, the interval of 30mm), and the rest are the same as in Embodiment 1. This example can be used for partition walls and general interior partition walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com