Plastering-free building brick and wall

A plaster-free and brick-laying technology, which is applied to walls, building components, buildings, etc., can solve problems such as the influence of the construction progress on the stability of the wall, the impact on the construction progress, and the large consumption of cement mortar, so as to achieve good coordination, save construction time, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

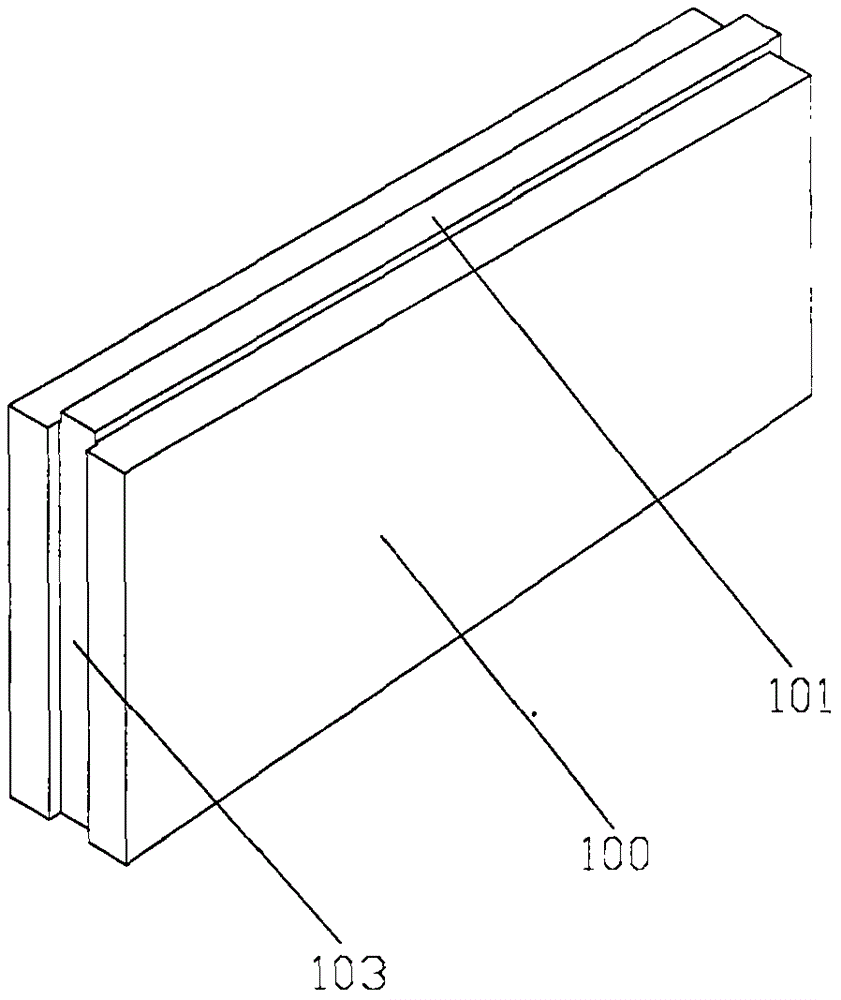

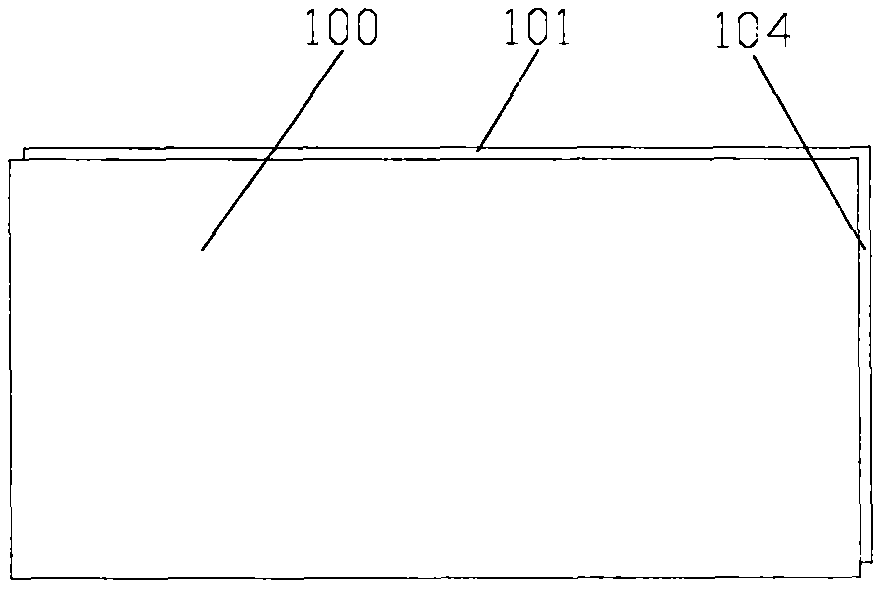

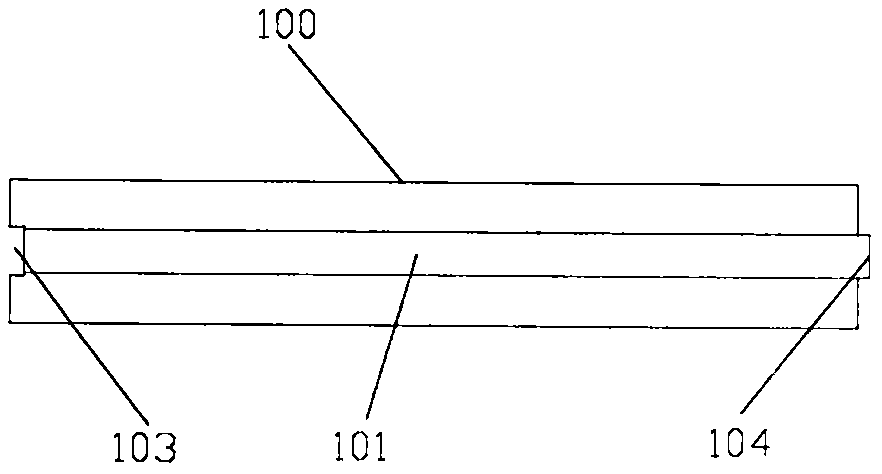

[0047] Such as Figure 1 to Figure 8 As shown: a kind of plaster-free bricklaying provided by Embodiment 1 of the present invention, which includes a brick body 100 with a rectangular structure. The lower end surface of the brick body 100 is provided with a first installation recess 102 arranged along the length direction, the first installation recess 102 cooperates with the first installation protrusion 101, and the left end surface of the brick body 100 is provided with a second installation along the height direction. Recess 103, the right end surface of the brick body 100 is provided with a second installation protrusion 104 arranged along the height direction, the second installation protrusion 104 cooperates with the second installation recess 103, the first installation protrusion 101 and the second installation protrusion The structure of the portion 104 is the same and the cross section can be any one of rectangle, semicircle, inverted V shape or inverted dovetail sh...

Embodiment 2

[0049] Such as Figure 9 to Figure 14 As shown: it is a kind of plaster-free bricklaying provided by Embodiment 2 of the present invention. The difference from Embodiment 1 is: the upper end surface of the brick body 200 is provided with two first installation protrusions 201 arranged along the length direction, and the brick The lower end surface of the body is provided with two first installation recesses 202 arranged along the length direction, the left end surface of the brick body 200 is provided with two second installation recesses 203 arranged along the height direction, and the right end surface of the brick body 200 is provided with two The second installation protrusion 204 arranged along the height direction; the two first installation protrusions and the two first installation recesses are respectively arranged at intervals on the upper end surface and the lower end surface of the brick body along the length direction, and the two second installation protrusions an...

Embodiment 3

[0051] Such as Figure 15 to Figure 20 As shown: it is a kind of plaster-free bricklaying provided by Embodiment 2 of the present invention. The difference from Embodiment 1 is that the length, width and height of the brick body 300 are 600mm, 250mm and 300mm respectively, and the first installation convex part The widths of the first and second mounting protrusions are both 46mm, and the widths of the first groove and the second groove are both 50mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com