Internal engagement spherical gear pump

An internal meshing and ball tooth technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of cost reduction and difficult gear processing, and achieve the effects of reducing production costs, simple processing, and increasing rated pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

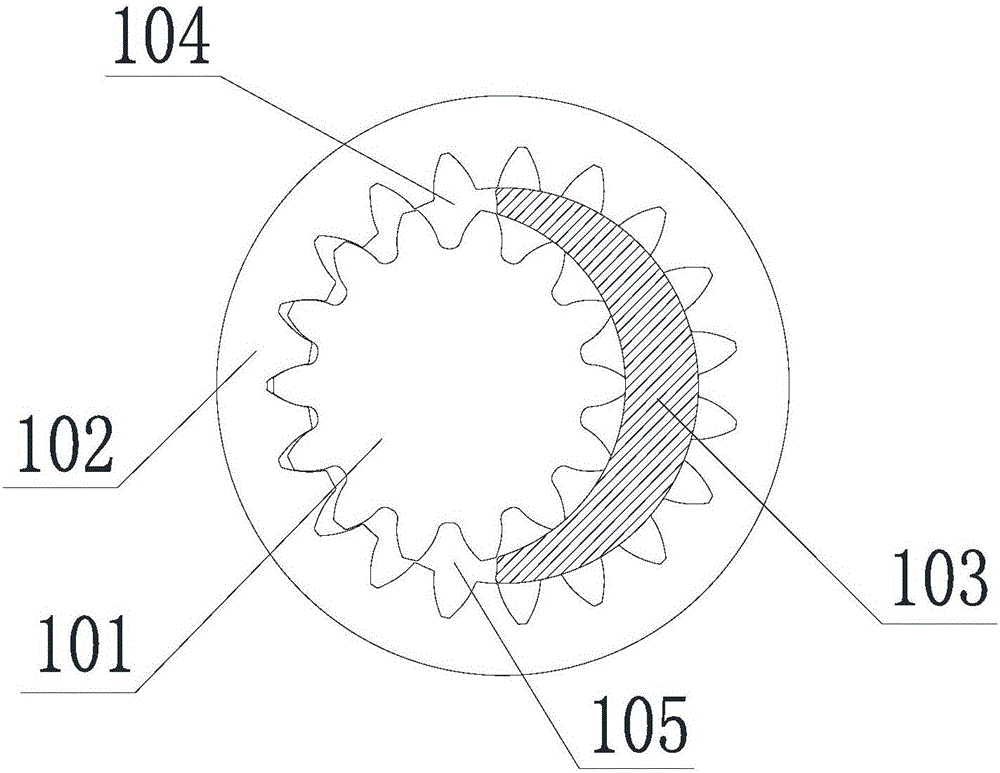

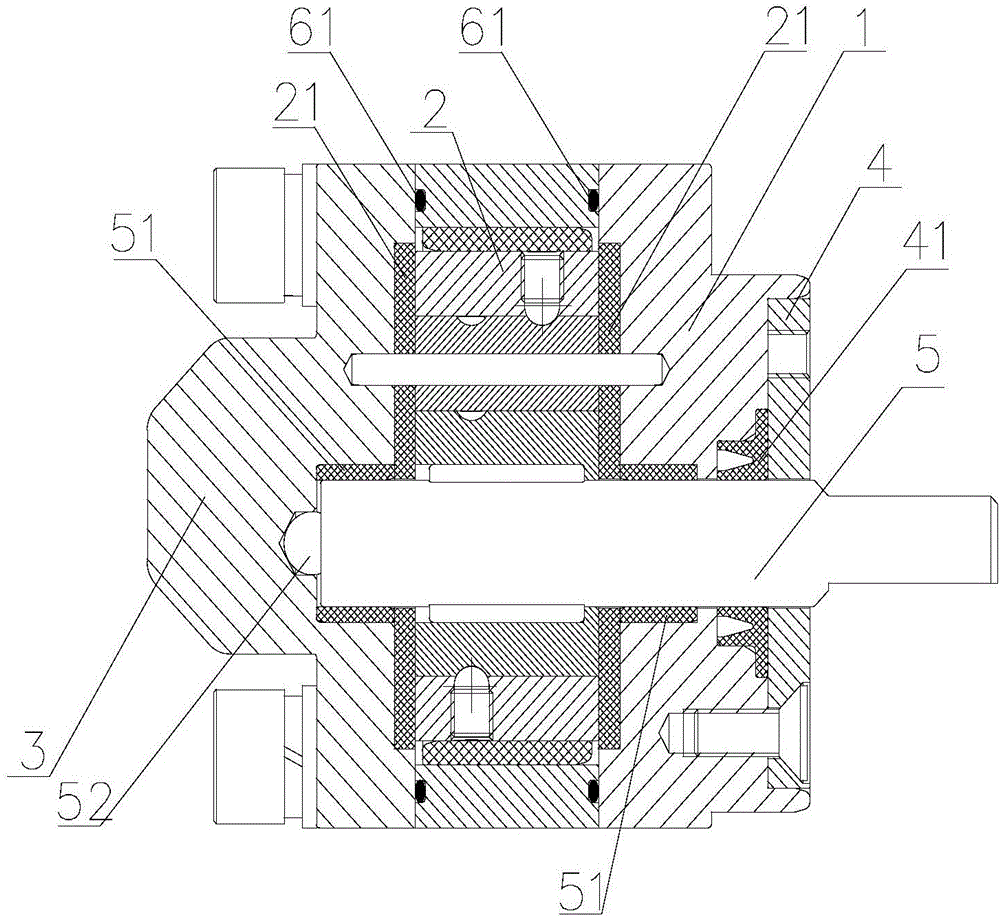

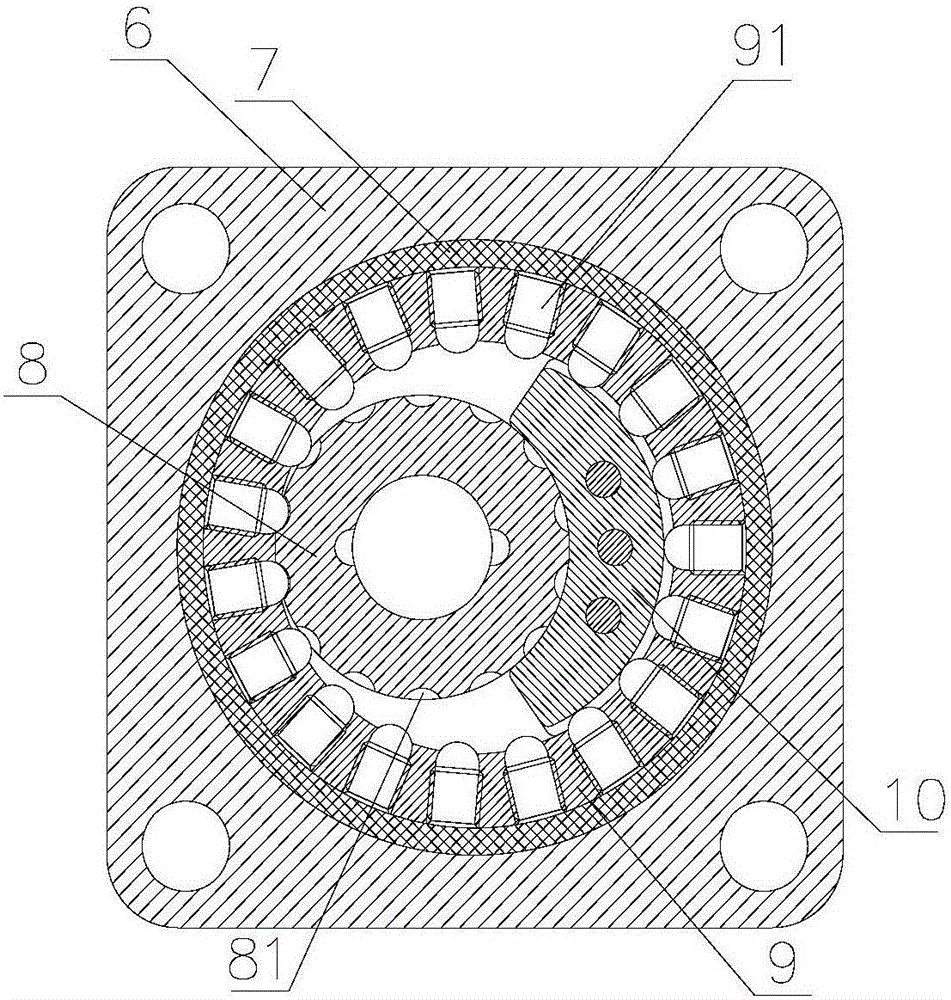

[0024] Example 1, such as Figure 2-3 As shown, this embodiment discloses an internally meshing ball-tooth pump. The ball-tooth pump includes a front end cover 1 and a rear end cover 3. The outer surface of the front end cover 1 is provided with a sealing ring gland 4, and the sealing ring gland 4 A seal ring 41 is installed between the front end cover and the front end cover 1, and the ball tooth assembly 2 is between the front and rear end covers. The shaft 5 penetrating into the ball tooth pump passes through the above seal ring 41 and passes through the bearing 51 to the front end cover 1 and the rear end respectively. The cover 3 is connected, and the support and fixation of the shaft 5 is realized through the above-mentioned bearings 51 installed on the front and rear end covers; the button assembly 2 includes a pump body 6, and an outer rotor 9 and an inner rotor 8 are arranged in the pump body 6, and the outer rotor The outer surface of 9 is connected with the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com