Manual plunger valve device with upper valve seat body and lower valve seat body capable of being sealed independently

A plunger valve and valve seat technology, which is applied in the field of manual plunger valve devices, can solve the problems that the valve seat cannot be sealed separately, the lower valve stem is squeezed, etc., and achieve good guidance, small valve operating torque, and excellent friction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

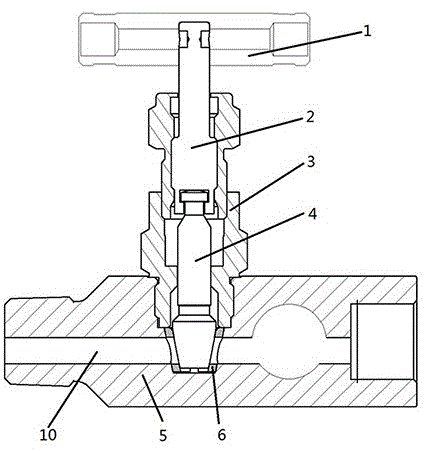

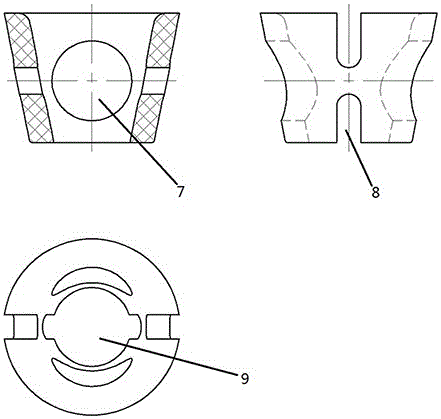

[0023] Such as figure 1 , figure 2 Shown is a manual plunger valve device in which the upper and lower valve seats can be sealed separately, including a handle 1, a bracket 3, a valve stem 4, a valve body 5, a flow channel 10, a push rod 2, and a valve seat 6; Turn the handle and connect to one end of the push rod 2 perpendicular to the axis of the push rod 2. The push rod 2 is 30cm long and 6cm in diameter. It is connected with the support 3 along the axis direction of the support 3 with a threaded structure. The support 3 is 50cm high and connected above the valve body 5. Vertical to the valve body 5, the valve body 5 is a cylindrical structure with a length of 60cm, an outer diameter of 20cm, and an inner diameter of 8cm. The length of the rod is 30cm and the diameter is 6cm. The end connecting the push rod 2 and the valve rod 4 is provided with a slotted hole. The draw-in groove cooperates with the draw-in shoot on the push rod 2, and the push rod 2 and the valve stem 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com