Automatic LNG and CNG switching system and control method thereof

An automatic switching and subsystem technology, which is applied in the field of LNG, CNG automatic switching system and its control, can solve the problems of users' economic loss, production stoppage, gas pressure regulating device cannot be used universally, etc., and achieve the effect of avoiding economic loss and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

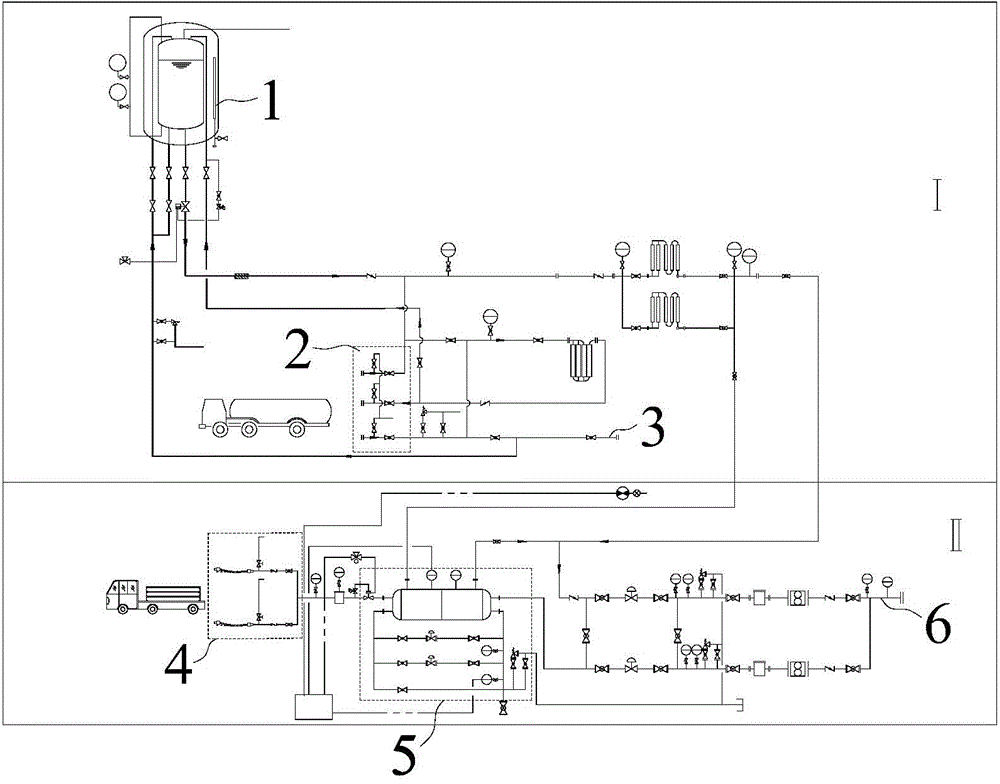

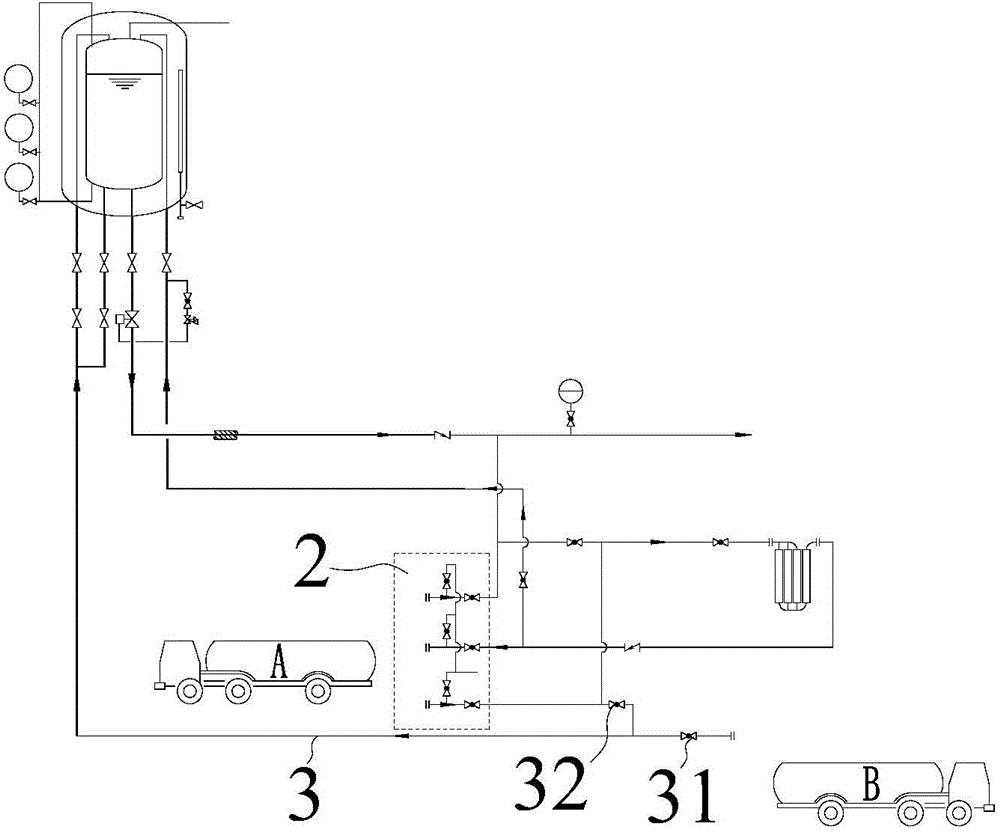

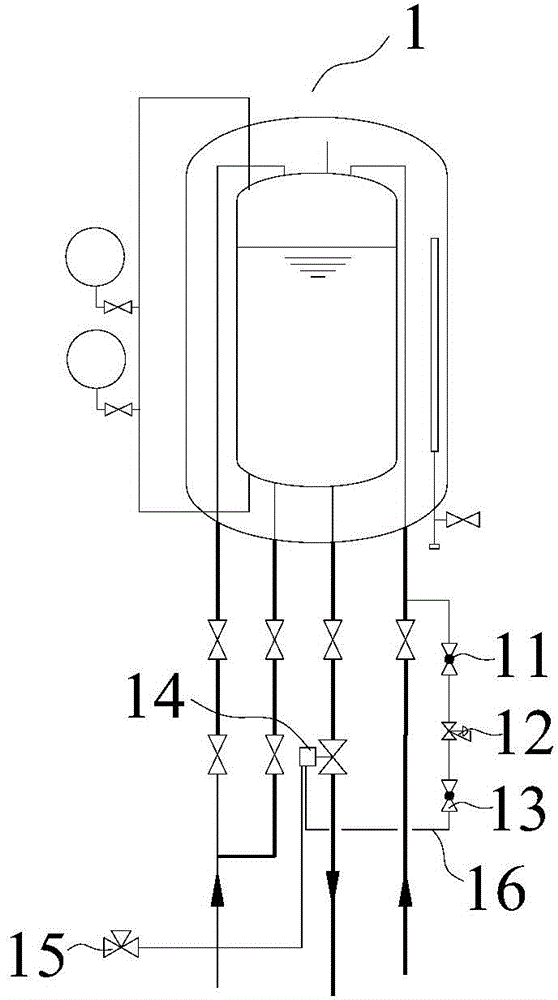

[0026] Such as Figure 1-4 As shown, an automatic switching system between LNG and CNG includes a control system, a parallel LNG gas supply subsystem and a CNG gas supply subsystem, and the parallel LNG gas supply subsystem and the CNG gas supply subsystem pass through a shared heat exchange tank 5 Perform heat exchange, and supply air through the air supply pipeline 6 connected with the shared heat exchange tank 5;

[0027] Wherein, the shared type heat exchange tank 5 includes a tank body 50, heaters 54 located at both ends of the tank body 50, two-stage CNG heat exchange tubes extending into the inside of the tank body 50 from both ends, and two-stage CNG heat exchange tubes extending into the inside of the tank body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com