A bottom-mounted low-nitrogen burner suitable for large-scale load adjustment

A low-nitrogen burner and load adjustment technology, which is applied to the burner, burner, and combustion type of powder fuel, can solve the problems of easy formation of local high temperature, reduce air volume ratio, and fast outlet wind speed, etc., to increase load The effect of adjusting the range, solving the flame eccentricity and prolonging the burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

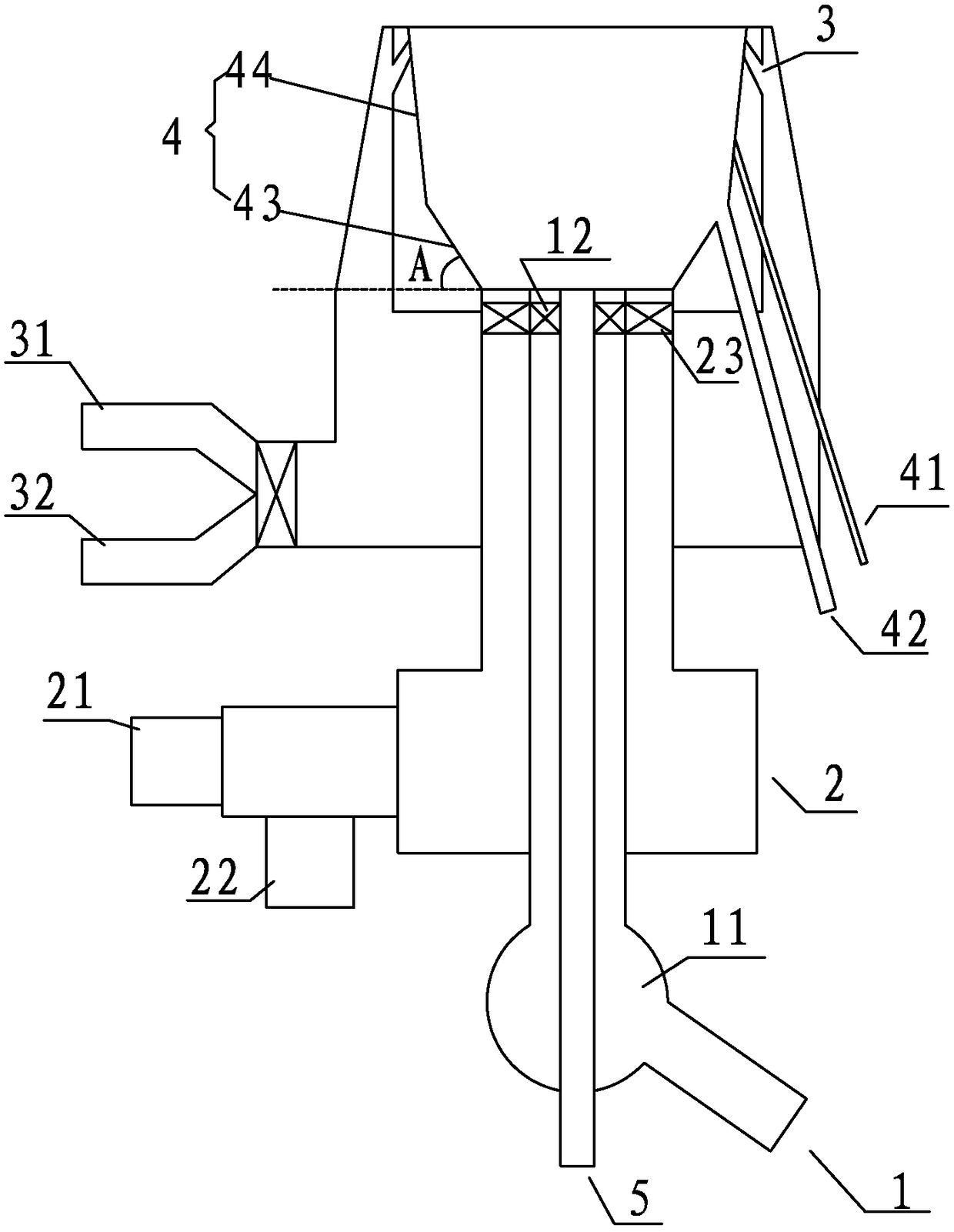

[0030] Referring to Figure 1, a bottom-mounted low-nitrogen burner suitable for large-scale load adjustments includes a central flame regulating pipe 5, a primary air pipe 1, a secondary air pipe 2, and a tertiary combustion-supporting device 3 that are sequentially nested from the inside to the outside. , the inlet of the primary air duct 1 is provided with a pulverized coal flow stabilization mechanism 11, the outlet of the primary air duct 1 is provided with a primary air cyclone 12, the inlet of the secondary air duct 2 is provided with an air premixing device, and the secondary air duct 2 The outlet of the outlet is provided with a secondary wind swirler 23, the outlet of the secondary air pipe 2 is also provided with a flame stabilizing device 4, and the air outlet of the tertiary combustion-supporting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com