3d print slice rapid generation method

A 3D printing and slicing technology, applied in the field of 3D printing, can solve problems such as low generation efficiency, complex data structure, and difficulty in implementation, and achieve the effects of improving efficiency, simplifying complexity, and reducing implementation complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

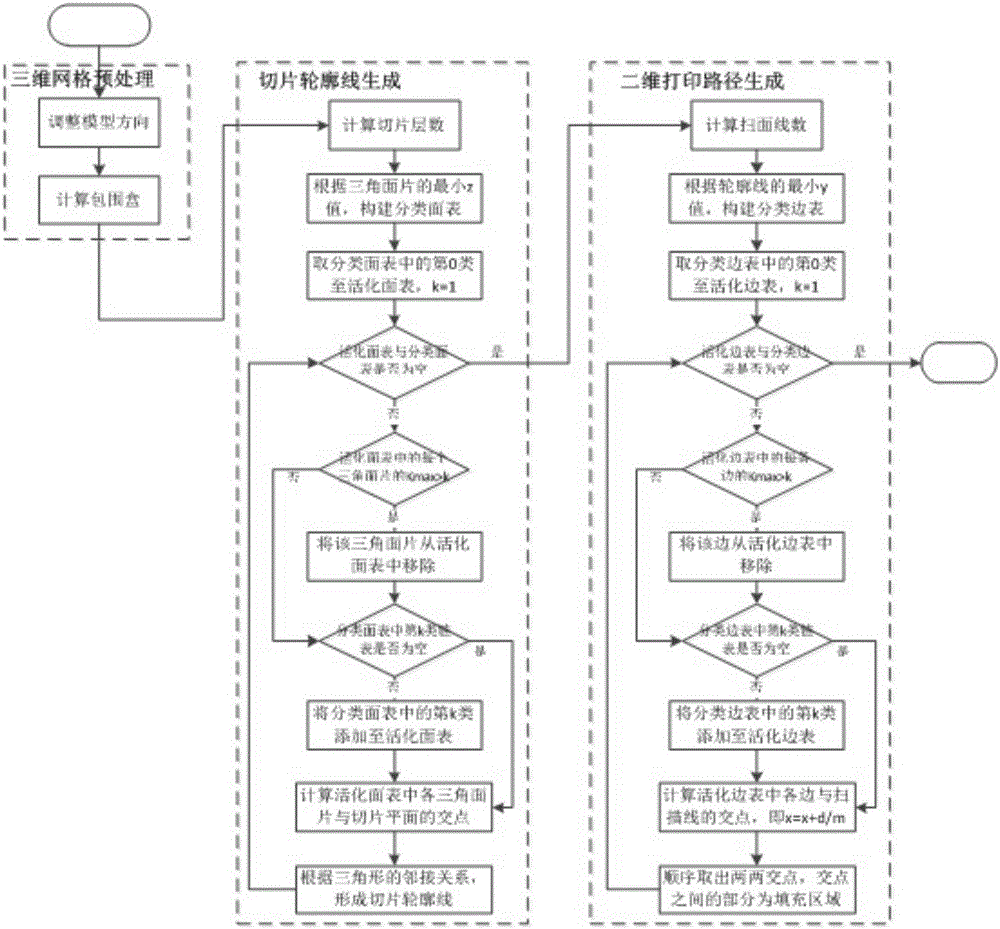

[0045] Such as image 3 As shown, the rapid generation of 3D printing slices is divided into three steps: the preprocessing of the 3D mesh, the generation of the slice outline and the generation of the printing path in the slice.

[0046] Input a 3D model, first adjust its direction and calculate its bounding box to determine the printing range of the 3D model, the number of slice layers and the number of scan lines.

[0047] Then, for each slice plane, the contour line where the 3D model intersects with the slice plane is calculated. Its specific steps include:

[0048] Step 1: Set d according to the layer thickness of 3d printing, and the printing range determined in preprocessing [z b ,z t ], determine the number of sliced layers n=(z t -z b ) / d;

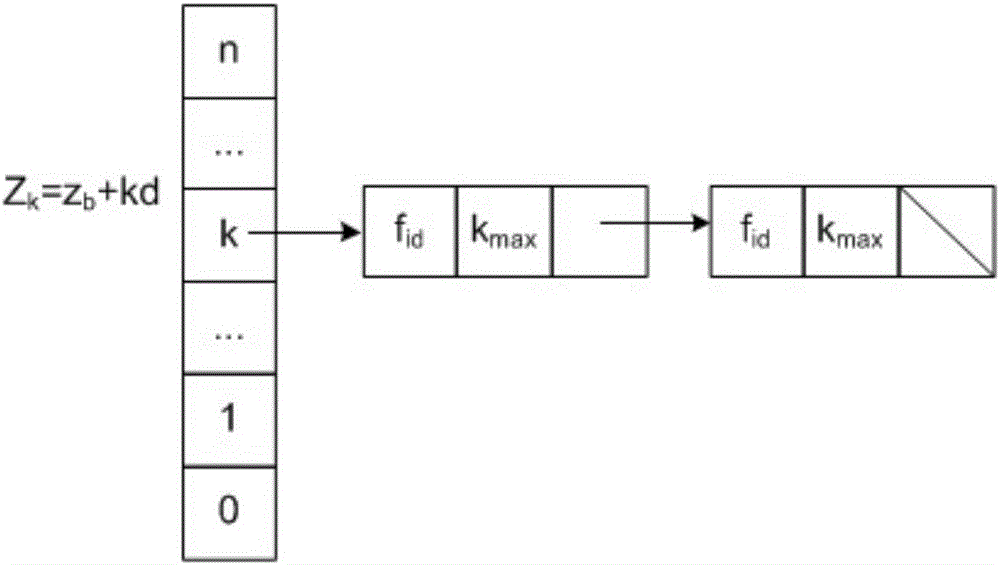

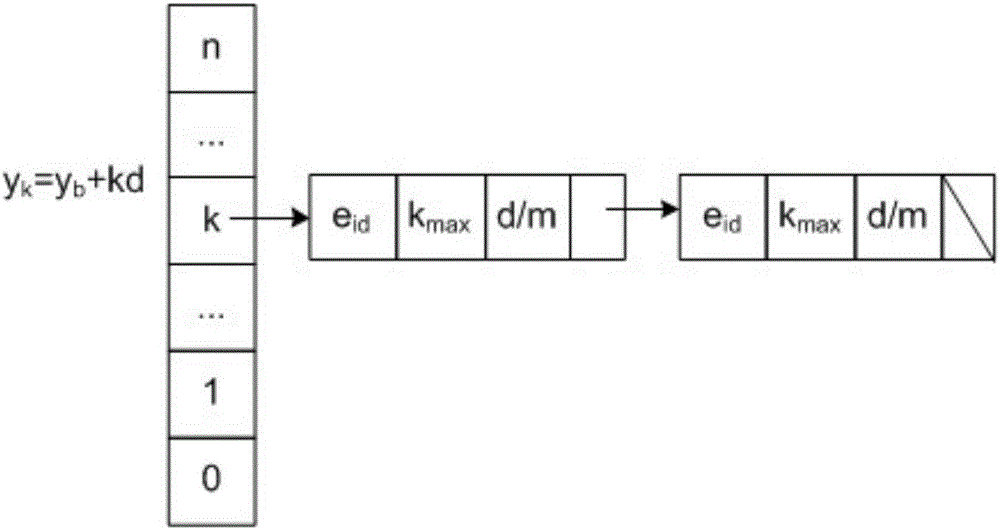

[0049] Step 2: Press each triangle face in the triangle mesh according to the minimum z value z among the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com