Cable maintenance robot

A robot and cable technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of cable damage, cable material waste, etc., and achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained in conjunction with the embodiments below.

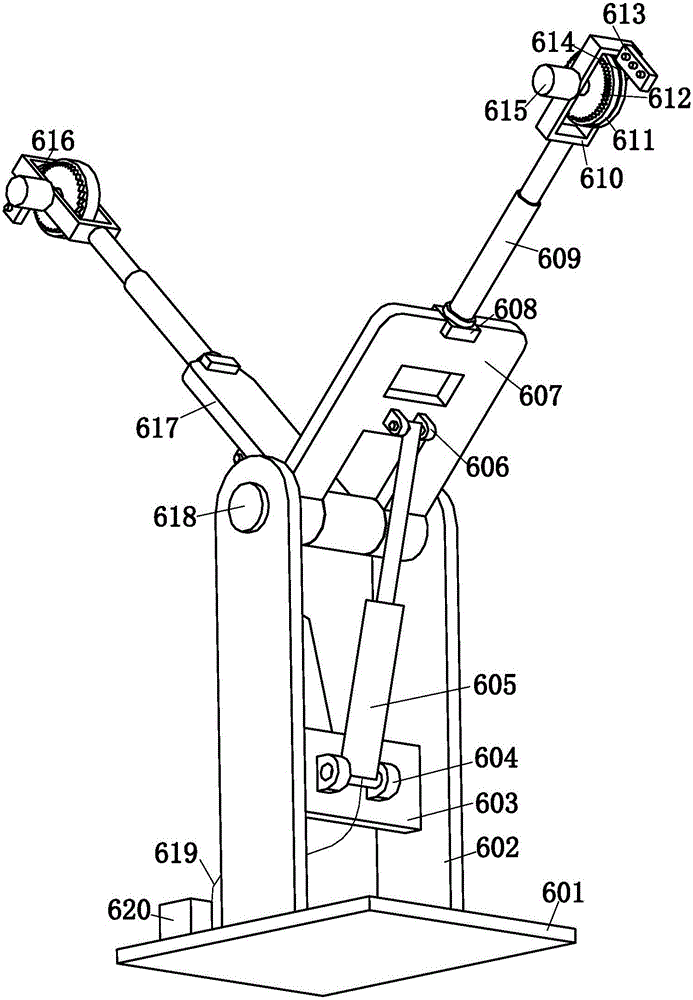

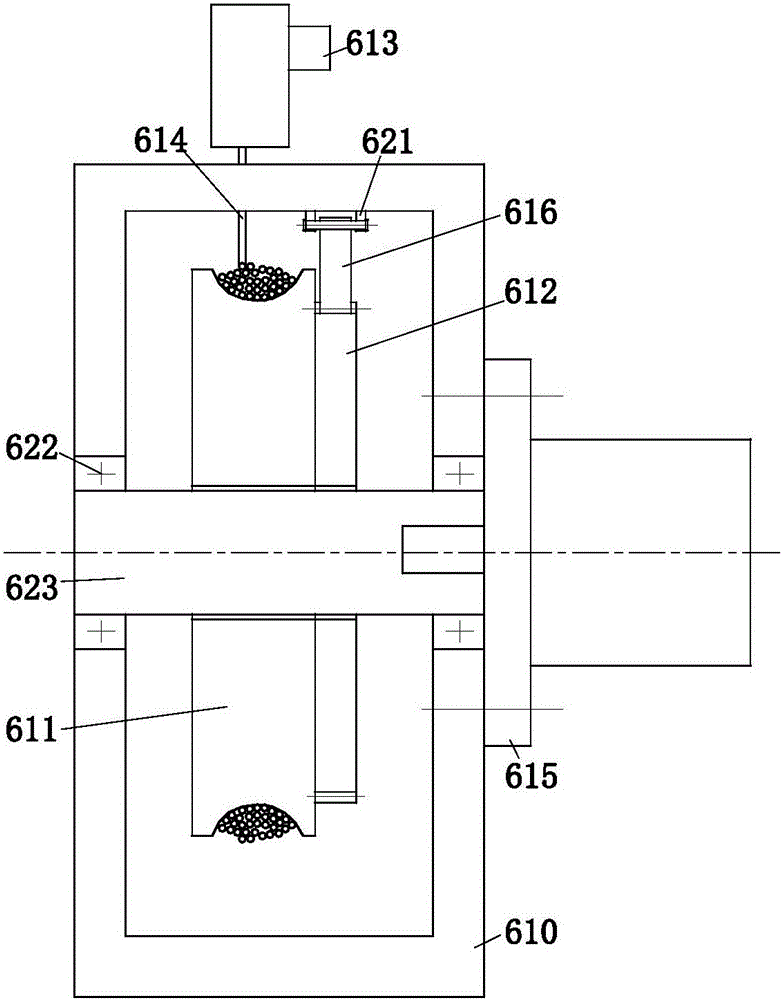

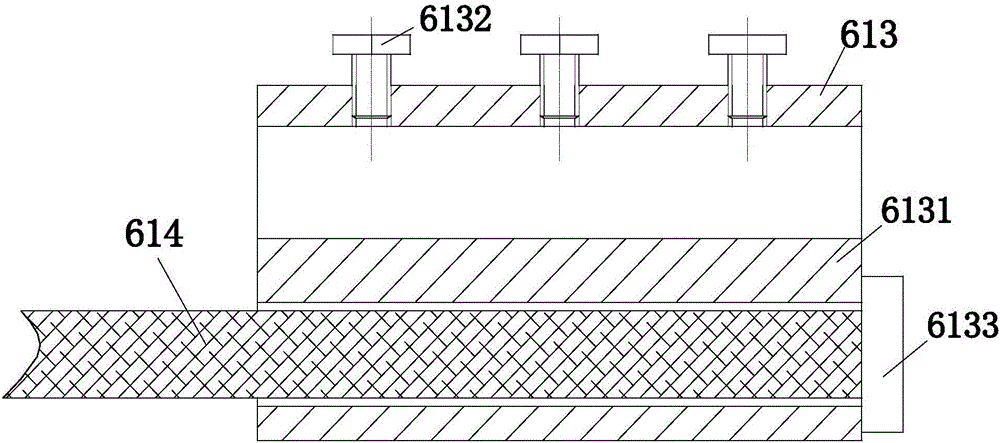

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, in the cable maintenance robot of the present invention, the emergency repair device includes an emergency repair adjustment plate 601, an emergency repair support frame 602, an adjustment bottom plate 603, an adjustment lower support 604, an adjustment cylinder 605, an adjustment upper support 606, Emergency repair mother board 607, hydraulic cylinder base 608, hydraulic cylinder 609, frame slewing frame 610, winding runner 611, ratchet wheel 612, end line locking device 613, flexible steel cable 614, gear motor 615, pawl 616, emergency repair company Plate 617, rotating pin 618, emergency repair air pipe 619, emergency repair air pump 620, pawl support 621, emergenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com