Substation system high-tension line maintenance gear transmission lifting type operating device

A high-voltage line, gear transmission technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of separation, worker's life safety injury, etc., and achieve the effect of avoiding electric shock events and life safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

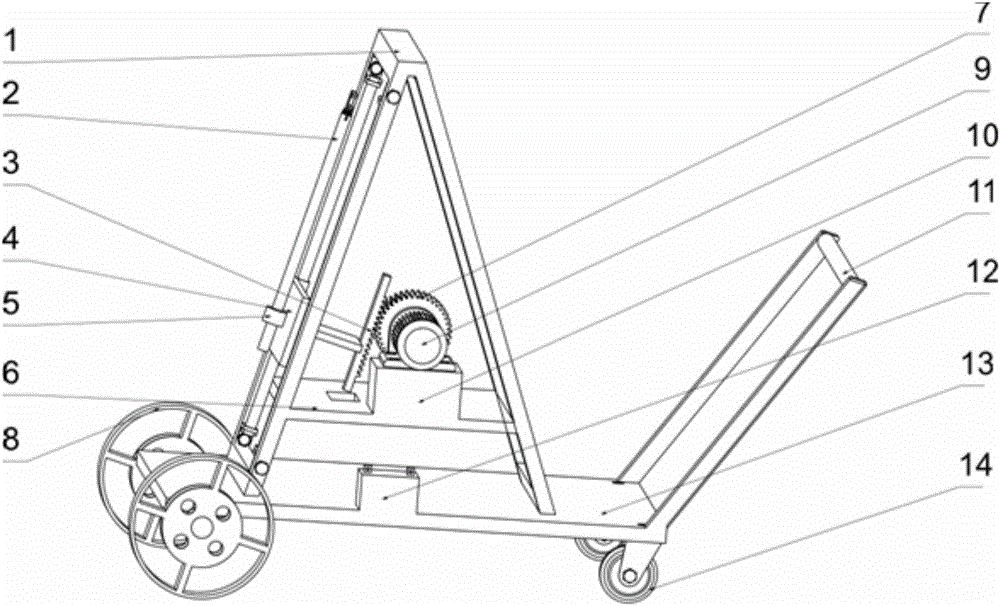

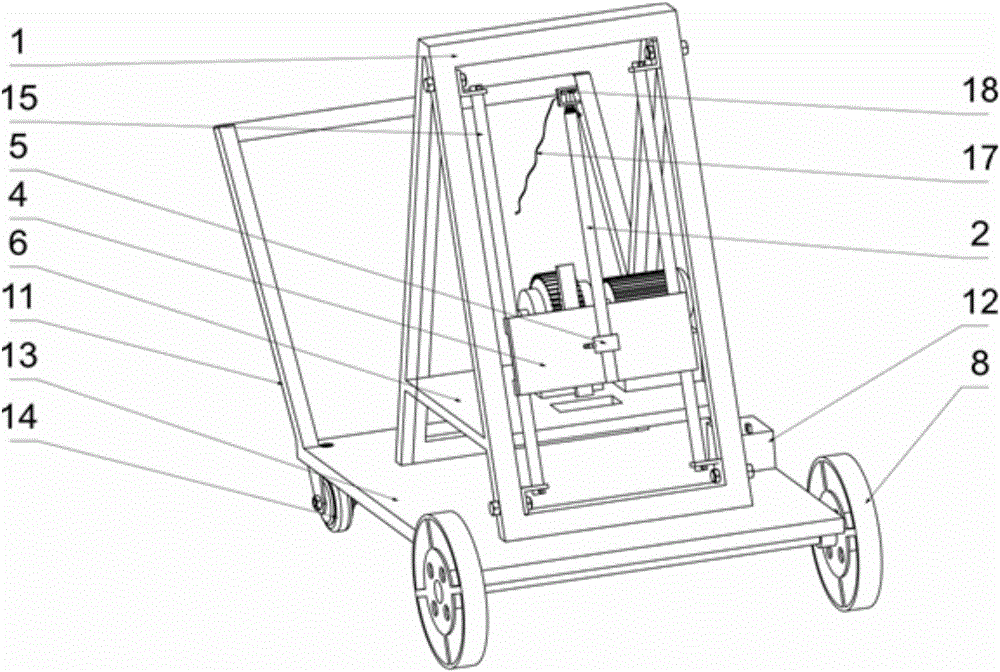

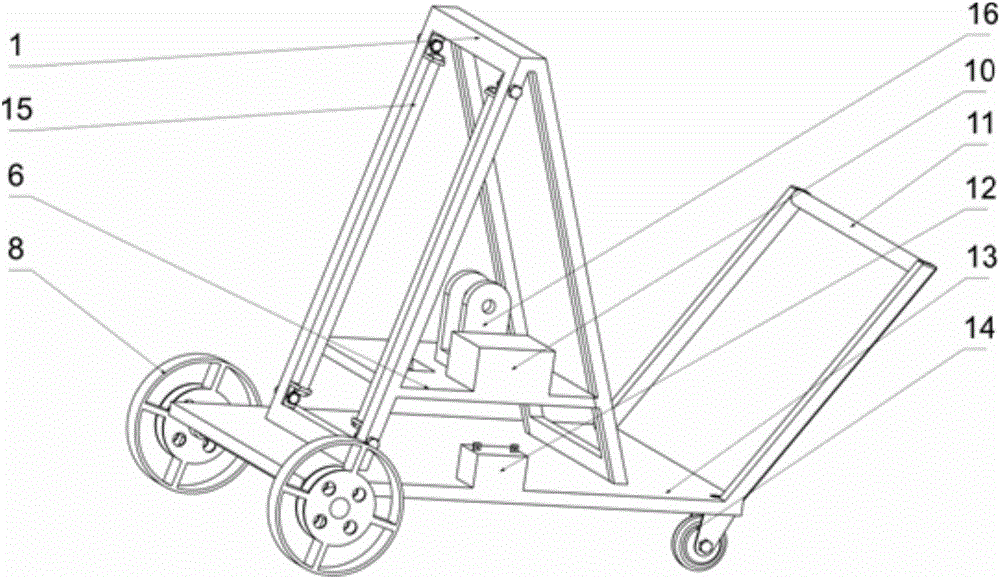

[0027] Such as Figure 1 to Figure 5 As shown, the high-voltage line maintenance gear transmission lifting operation device of the substation system according to the present invention includes a walking bracket, a gear transmission mechanism and a lifting mechanism. The specific structure and connection relationship are as follows:

[0028] Described walking support comprises support 1, second baffle plate 6, front wheel 8, motor support 10, handle 11, battery 12, first baffle plate 13, universal wheel 14, slide rail 15 and gear support 16, front wheel 8 is located in front of the first baffle 13, the universal wheel 14 is located behind the first baffle 13 as a rear wheel, the handle 11 is welded behind the first baffle 13, and the bracket 1 is welded in the middle of the first baffle 13, The second baffle plate 6 is installed in the middle and lower position of the support 1. On the second baffle plate 6, a motor support 10 and a gear support 16 are welded. The top of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com