Plug-in type stator component

A plug-in, stator technology, applied in the field of stator parts, can solve problems such as unsafe use, motor open circuit, inconvenient installation, etc., and achieve the effect of good use performance, short circuit avoidance, and open circuit avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

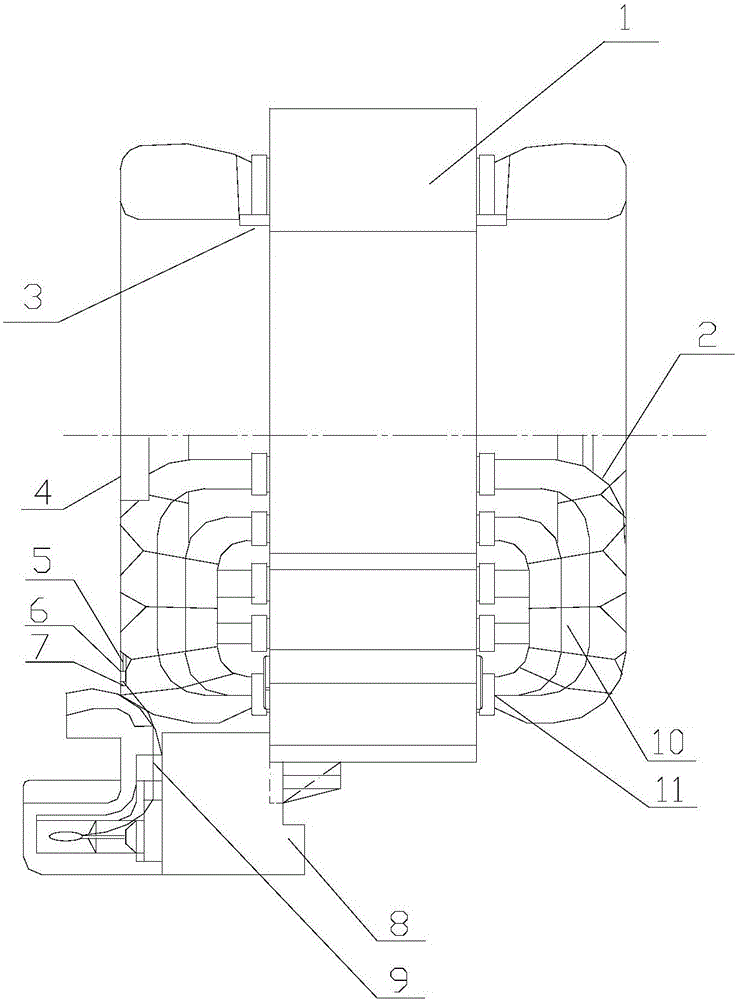

[0011] Example. A plug-in stator part, constituted as figure 1 As shown, it includes a hollow stator 1, the inner ring of the hollow stator 1 is provided with a plurality of winding slots, and a plurality of concentric windings 2 are arranged in the plurality of winding slots. Inter-slot insulation layers 11 are provided between them, and interphase insulation layers 10 are provided between the concentric windings; the concentric windings 2 are connected with inserts 8 through lead-out wires 9, and the inserts 8 are fixed on the hollow stator 1 (can be passed through the hollow stator 1 has a slot, and the plug-in is tightly fitted in the slot,), and the concentric winding 2 is provided with a 135-degree thermal protector 4.

[0012] A heat-shrinkable tube 5 is arranged on the lead-out line, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com