Capacitor carrier tape stripping tension detection device

A technology of tension detection and capacitors, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve customer troubles, affect product packaging, affect work efficiency and other problems, and achieve the effect of excellent packaging, simple structure, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

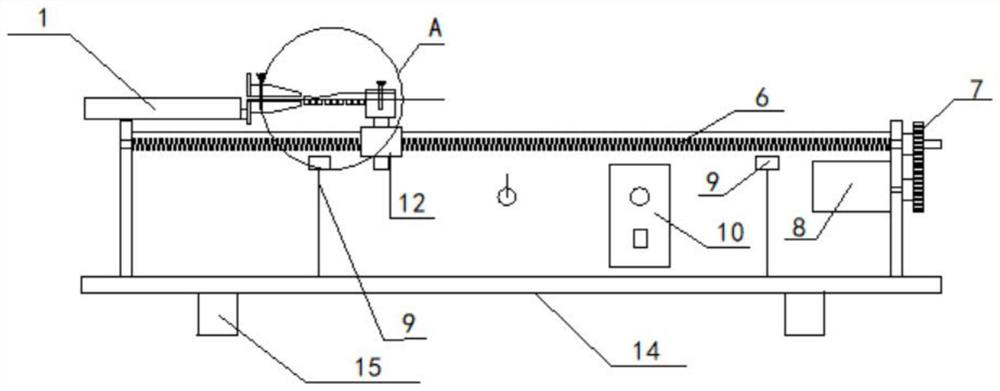

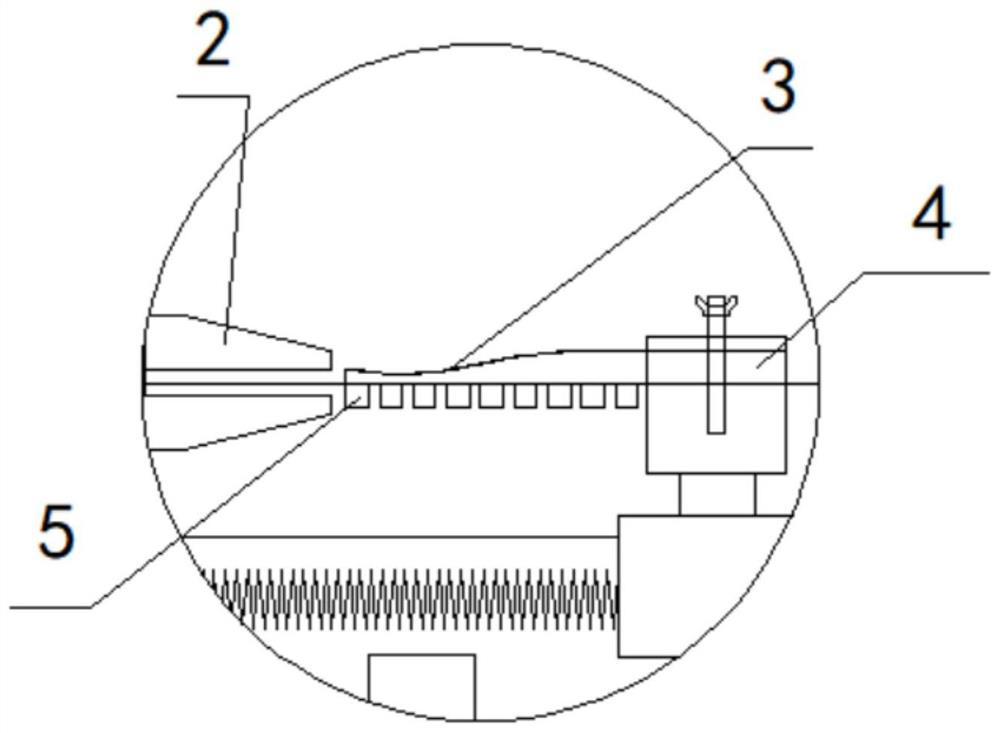

[0017] Embodiment one: Figure 1-Figure 2 Shown is a capacitor tape stripping tension detection device, the capacitor tape stripping tension detection device is mainly composed of: a base 14, a foot 15, a tension measuring instrument 1, a carrier plate clamp 2, a cover tape clamp 4 and a combination of a transmission mechanism Formed, the feet 15 are arranged on the bottom of the base 14, the tension measuring instrument 1 is fixed on the base 14, the carrier clamp 2 and the measuring needle of the tension measuring instrument 1 connected, the cover belt clamp 4 is connected with the transmission mechanism, and the transmission mechanism is arranged on the base 14; the transmission mechanism is mainly composed of a screw rod 6, a transmission gear 7 and a speed regulating motor 8 , one end of the screw rod 6 is rotatably connected to the base 14, the other end of the screw rod 6 is placed outside the base 14 and connected to the speed regulating motor 8 through the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com