Reelable film LED lamp and manufacture method thereof

A technology of LED lamps and manufacturing methods, applied in lighting and heating equipment, electrical components, circuits, etc., can solve the problems of LED circuit short circuit, mutual integration, non-waterproof structure, etc., and achieve the effect of increasing the projection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

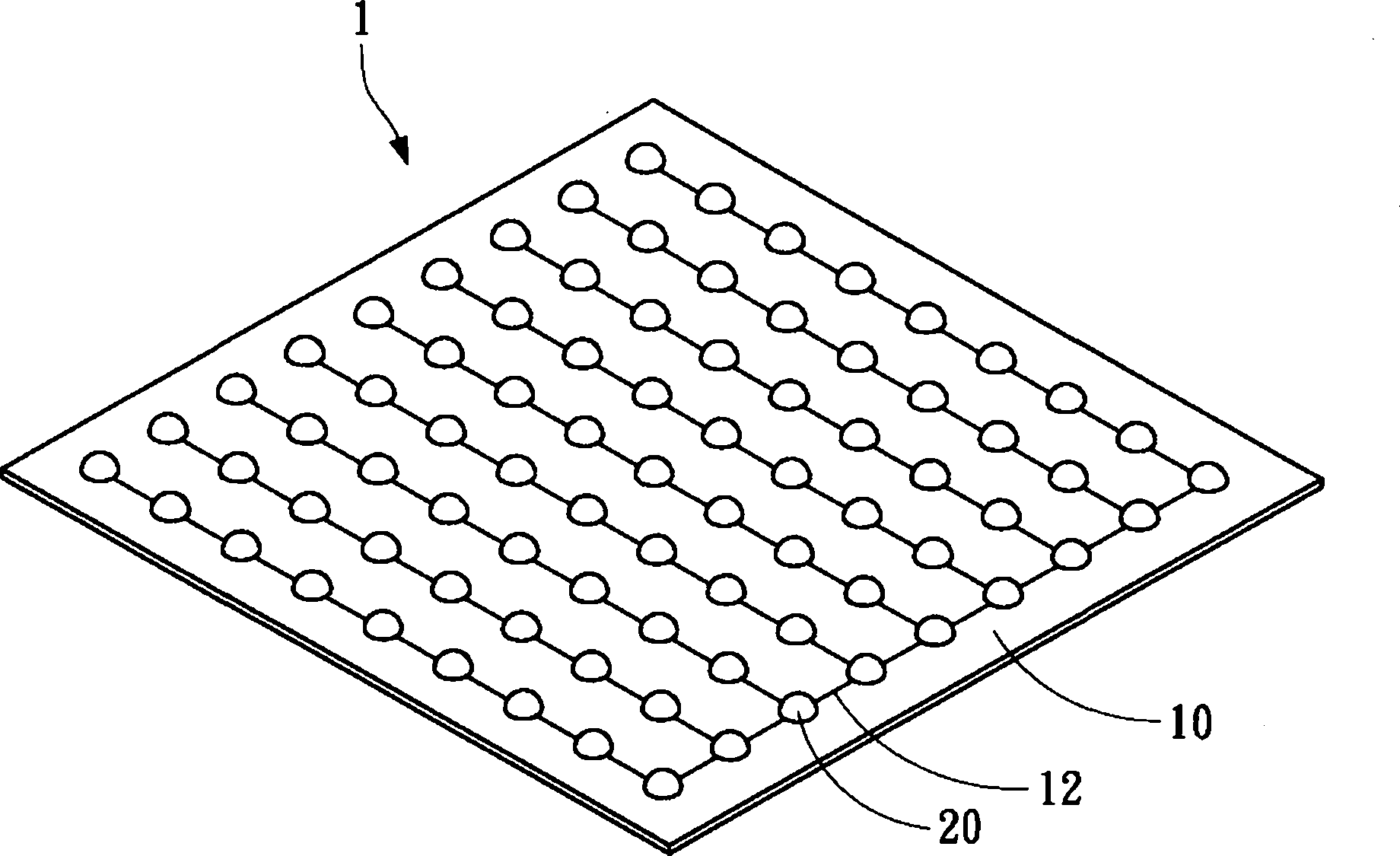

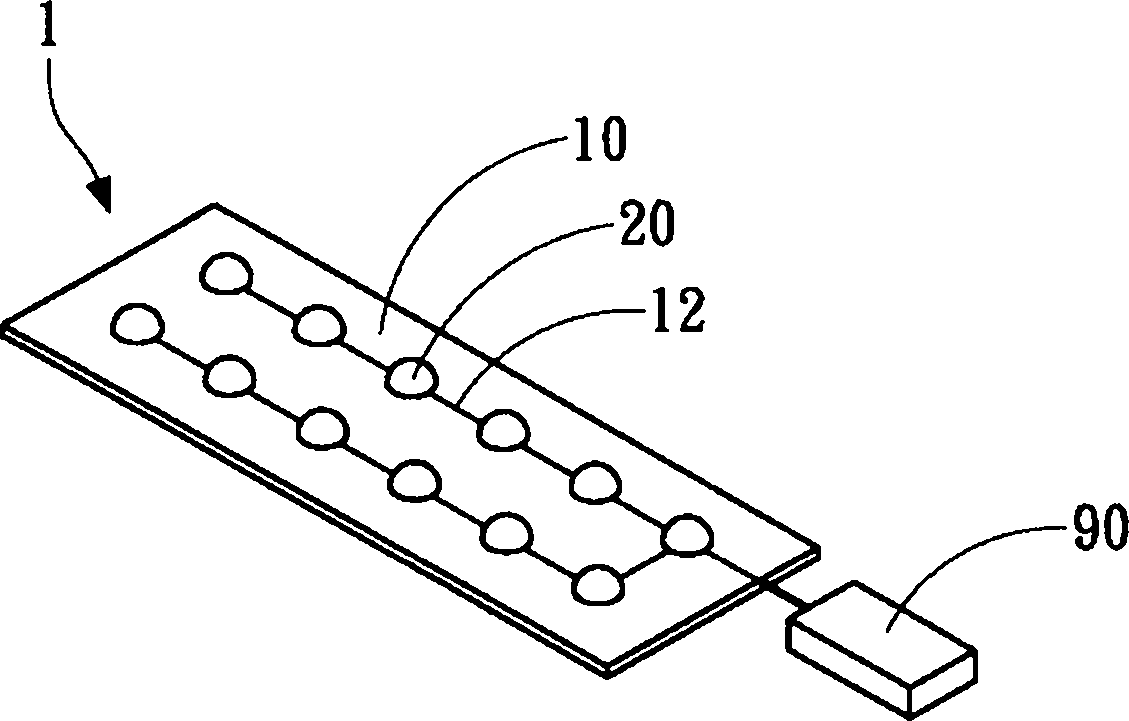

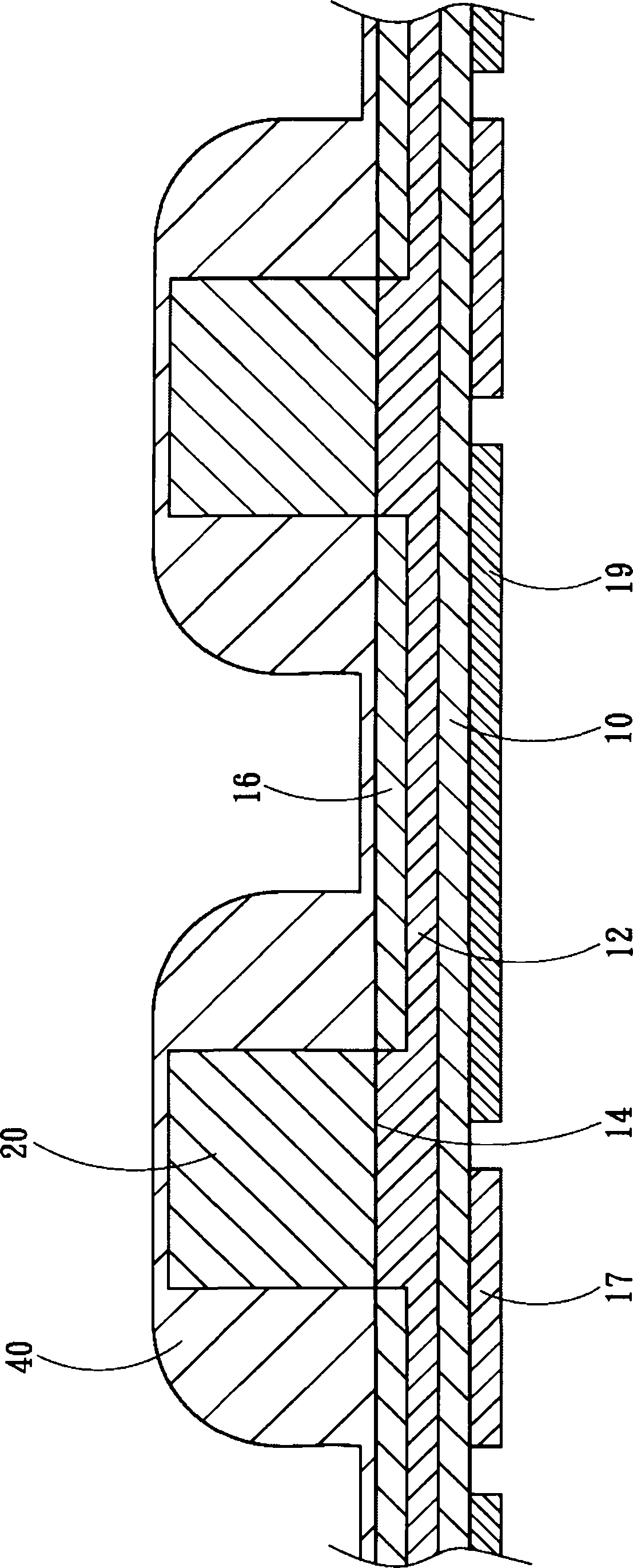

[0038] Such as Figure 1A , Figure 1B , figure 2 and image 3 Shown is the first embodiment of the rollable film LED lamp of the present invention.

[0039] The rollable film LED lamp 1 of the present invention includes: a film 10 , a circuit 12 , a plurality of electrical connection pads 14 , a protective paint 16 , a plurality of light emitting diodes 20 , and a waterproof layer 40 .

[0040] The film 10 is made of rollable materials, such as polyethylene terephthalate (PET), polyvinyl chloride (PVC), polyethylene (PE), polyimide (PI) and other materials, but the present invention It is not limited to this. Here, the film 10 can be made of transparent material, or different colors of pigments can be mixed to present different colors.

[0041] The circuit 12 is printed on one side of the film 10 by a bendable conductive material. Here, the circuit 12 can preferably be made of silver paste (containing silver, Filler, etc.), so that the film 10 will not cause damage when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com