Cold-pressed self-adhesive tape

A self-adhesive tape, cold pressing technology, applied in the direction of adhesives, adhesive types, natural rubber adhesives, etc., can solve the problems of weak tape toughness, thickened tape thickness, poor tensile strength, etc., to achieve maintenance Good performance, easy to stick, strong sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

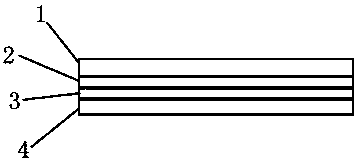

[0037] Such as figure 1 As shown, the cold-pressed self-adhesive tape provided by the present invention includes PET film layer 1, acrylic pressure-sensitive adhesive layer 2, tissue paper layer 3, and natural latex layer 4 in order from top to bottom. The formula of the acrylic pressure-sensitive adhesive layer is: 30 parts of butyl acrylate; 130 parts of isooctyl acrylate; 20 parts of vinyl acetate; 6 parts of methacrylic acid; 5 parts of hydroxypropyl methacrylate; glycidyl methacrylate 3 parts of ester; 1 part of acrylamide; 0.16 parts of azobisisobutyronitrile; 0.35 parts of dibenzoyl peroxide; 80 parts of toluene; 120 parts of ethyl acetate; 3 parts of isocyanate. The natural latex layer formula is 100 parts of natural latex; 30 parts of rosin emulsion; 1 part of p-cresol and dicyclopentadiene copolymer. Finally, a cold-pressed self-adhesive tape is obtained through a rolling process. The thickness of the PET film layer is 25 μm; the thickness of the acrylic pressure-sen...

Embodiment 2

[0039] Such as figure 1 As shown, the cold-pressed self-adhesive tape provided by the present invention includes PET film layer 1, acrylic pressure-sensitive adhesive layer 2, tissue paper layer 3, and natural latex layer 4 in order from top to bottom. The formula of the acrylic pressure-sensitive adhesive layer is: 25 parts of butyl acrylate; 121 parts of isooctyl acrylate; 23 parts of vinyl acetate; 4 parts of methacrylic acid; 7 parts of hydroxypropyl methacrylate; glycidyl methacrylate 4 parts of ester; 3 parts of acrylamide; 0.3 part of azobisisobutyronitrile; 0.5 part of dibenzoyl peroxide; 65 parts of toluene; 130 parts of ethyl acetate; 5 parts of isocyanate. The natural latex layer formula is 83 parts of natural latex; 40 parts of rosin emulsion; 2.5 parts of p-cresol and dicyclopentadiene copolymer. Finally, a cold-pressed self-adhesive tape is obtained through a rolling process. The thickness of the PET film layer is 20 μm; the thickness of the acrylic pressure-sens...

Embodiment 3

[0041] Such as figure 1 As shown, the cold-pressed self-adhesive tape provided by the present invention includes PET film layer 1, acrylic pressure-sensitive adhesive layer 2, tissue paper layer 3, and natural latex layer 4 in order from top to bottom. The formulation of the acrylic pressure-sensitive adhesive layer is: 32 parts of butyl acrylate; 135 parts of isooctyl acrylate; 18 parts of vinyl acetate; 5 parts of methacrylic acid; 6 parts of hydroxypropyl methacrylate; glycidyl methacrylate 3 parts of esters; 2 parts of acrylamide; 0.2 parts of azobisisobutyronitrile; 0.4 parts of dibenzoyl peroxide; 85 parts of toluene; 105 parts of ethyl acetate; 3.5 parts of isocyanate. The natural latex layer formula is 115 parts of natural latex; 25 parts of rosin emulsion; 2 parts of p-cresol and dicyclopentadiene copolymer. Finally, a cold-pressed self-adhesive tape is obtained through a rolling process. The thickness of the PET film layer is 28 μm; the thickness of the acrylic press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com