Dispersion disk

A technology for dispersing discs and discs, which is applied in mixers, chemical/physical/physicochemical processes, mixers with rotating stirring devices, etc., and can solve problems such as low quality of material mixing, insufficient material reaction, and single mixing form. , to achieve the effect of improving dispersion efficiency and dispersion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

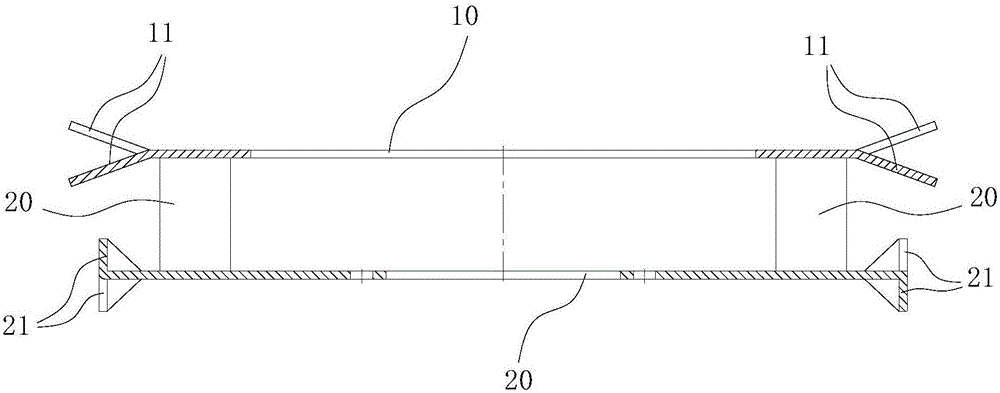

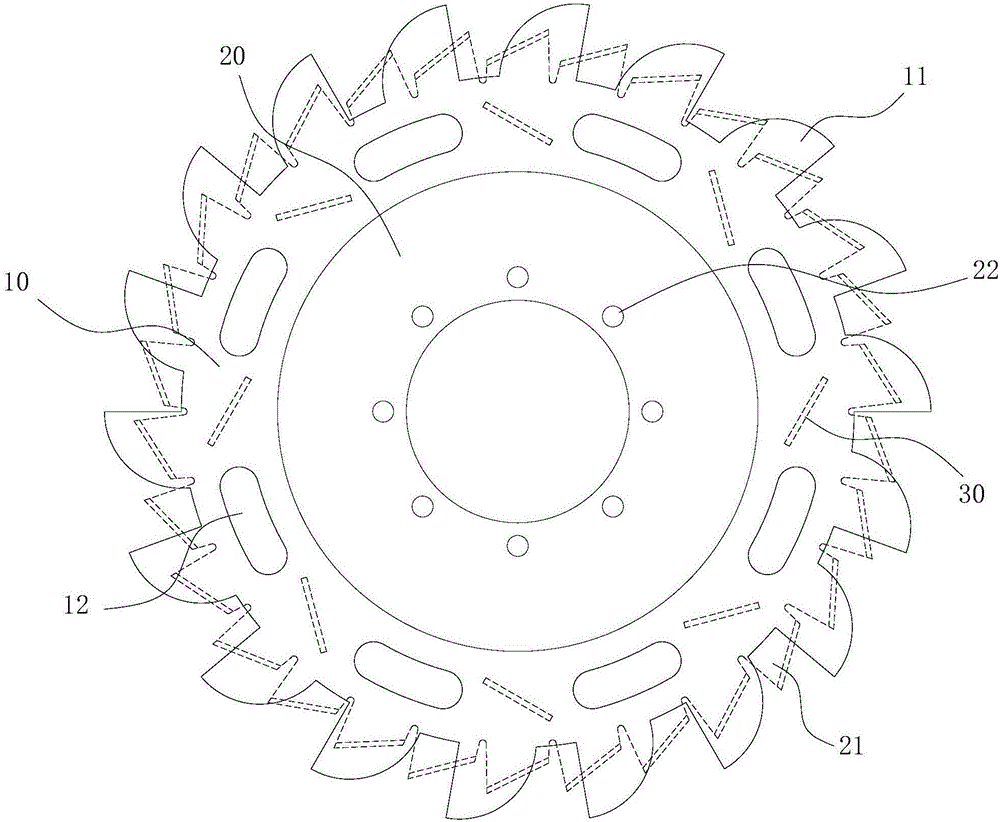

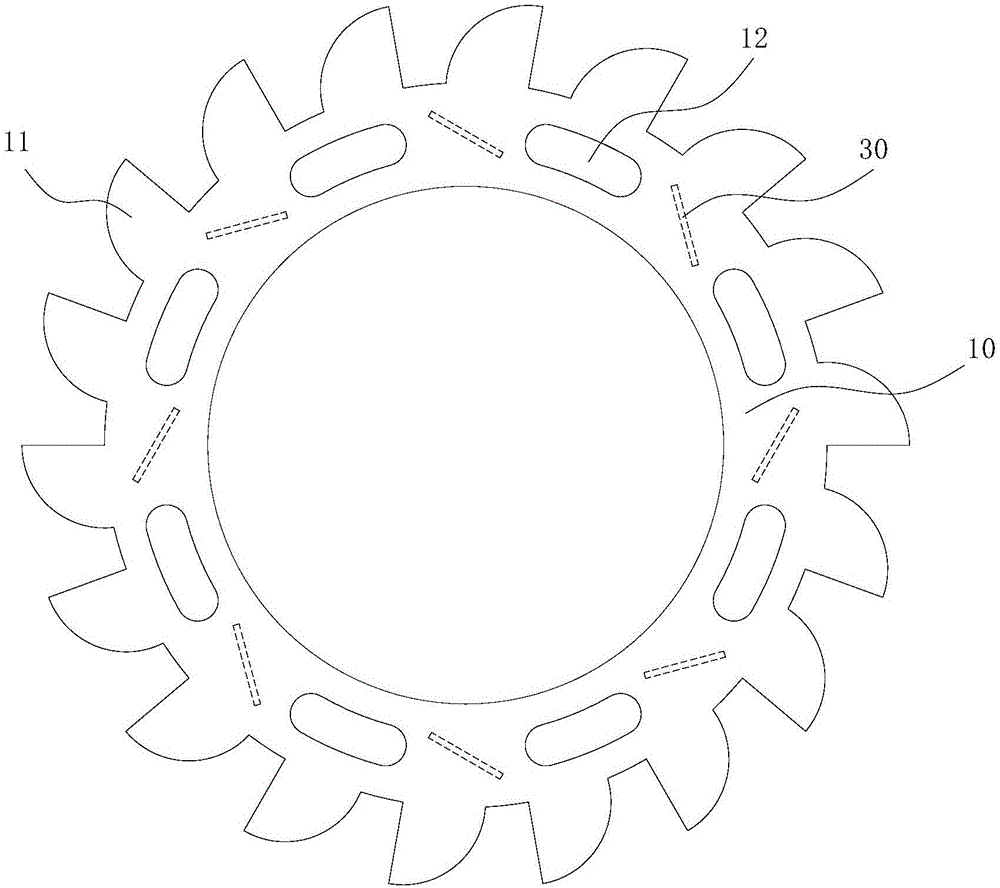

[0016] Such as Figure 1-4 As shown, a dispersing disk includes a first disk surface 10 and a second disk surface 20 arranged at intervals up and down, the first and second disk surfaces 10, 20 are connected by a web 30, and the first disk surface 10 There are sawtooths on the circumference of the second disc surface 20, and the sawtooth 11 on the first disc surface is bent obliquely upward or downward, and the sawtooth 21 on the second disc surface is bent vertically upward or downward; two adjacent serrations on the same disc surface The bending direction is opposite. The invention sets double-layer disks and redesigns the shape of the disks, which can drain materials while stirring, greatly improving the dispersion efficiency and quality of materials, and ensuring that materials can fully react.

[0017] Preferably, the sawtooth 11 on the first disk surface 10 is fan-shaped, one of the straight sides of the fan is arranged radially along the first disk surface, and the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com