Method for preparing double-metal MOFs material through metal replacement aided by steam

An auxiliary metal and bimetal technology, which is applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve the problems that the selective oxygen adsorption performance cannot be fully exerted and the exchange capacity is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the present invention in detail, the preparation method of the present invention will be described below in combination with specific experimental procedures.

[0025] Chemical substance material: Cu-BTC namely HKUST-1 is purchased directly by reagent company (BASF company production), anhydrous manganese chloride and N, N dimethylformamide (DMF), its combined preparation dosage is as follows: in grams, Milliliters are units of measurement.

[0026] Cu-BTC C 18 h 6 Cu 3 o 12 0.1g (0.17mmol)

[0027] Anhydrous Manganese Chloride MnCl 2 0.043g (0.34mmol)

[0028] N,N Dimethylformamide (DMF) C 3 h 7 NO 3mL (19.5mmol)

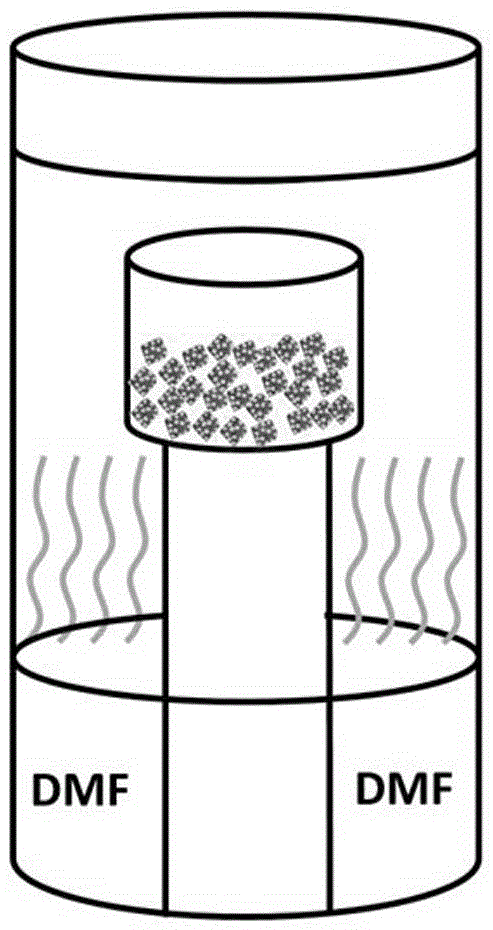

[0029] The method for preparing bimetallic Mn-Cu-MOFs material by DMF steam-assisted metal Mn replacement, the steps are:

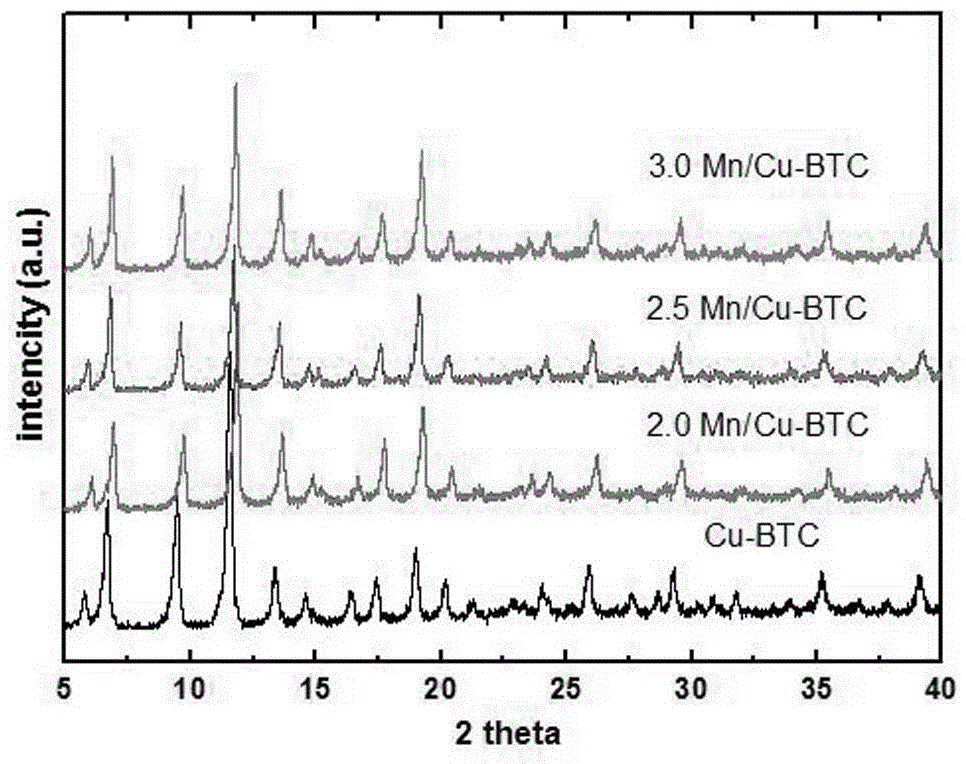

[0030] (1) Grinding Cu-BTC and anhydrous manganese chloride (0.34 / 0.17=2.0Mn / Cu-BTC)

[0031] Weigh 0.1g±0.001g of Cu-BTC, put it into an agate mortar, grind it for 5 minutes, and set aside; weigh 0.043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com