Worktable for processing composite material

A composite material and workbench technology, applied in workbenches, manufacturing tools, cleaning methods and utensils, etc., can solve problems such as physical health effects, increase, and inability to effectively reduce airborne dust, etc., to reduce difficulty, reduce floating dust, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

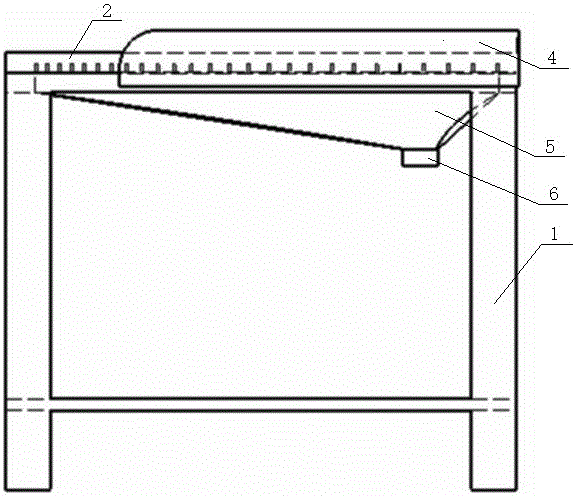

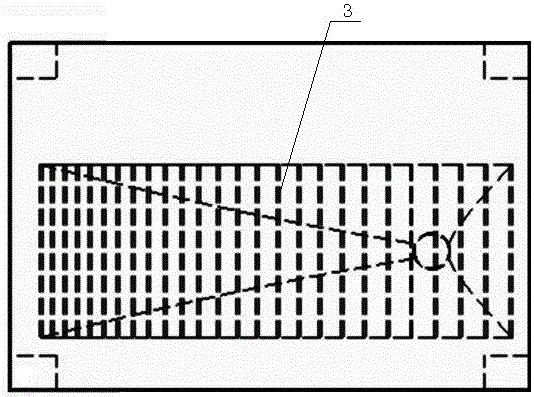

[0016] like figure 1 , figure 2 As shown, a workbench for processing composite materials of the present invention includes a main body composed of a wooden frame 1 and a fixed table top 2 on the wooden frame 1. The table top 2 is a detachable wooden board with multiple rows of gaps 3, The gaps 3 are arranged in an arithmetic sequence from left to right. The three sides of the table 2 are provided with an aluminum baffle 4 to block dust. The bottom of the table 2 is provided with a collection tank 5 for collecting dust. The material of the collection tank 5 is glass fiber reinforced plastic. The bottom of the 5 is provided with a suction port 6 connected to the suction device, and the suction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com