A high-precision anti-jump two-roll rolling mill

A high-precision, rolling mill technology, applied in the field of rolling mills, can solve problems such as uneven rolling, material waste, and reduced distance between two rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

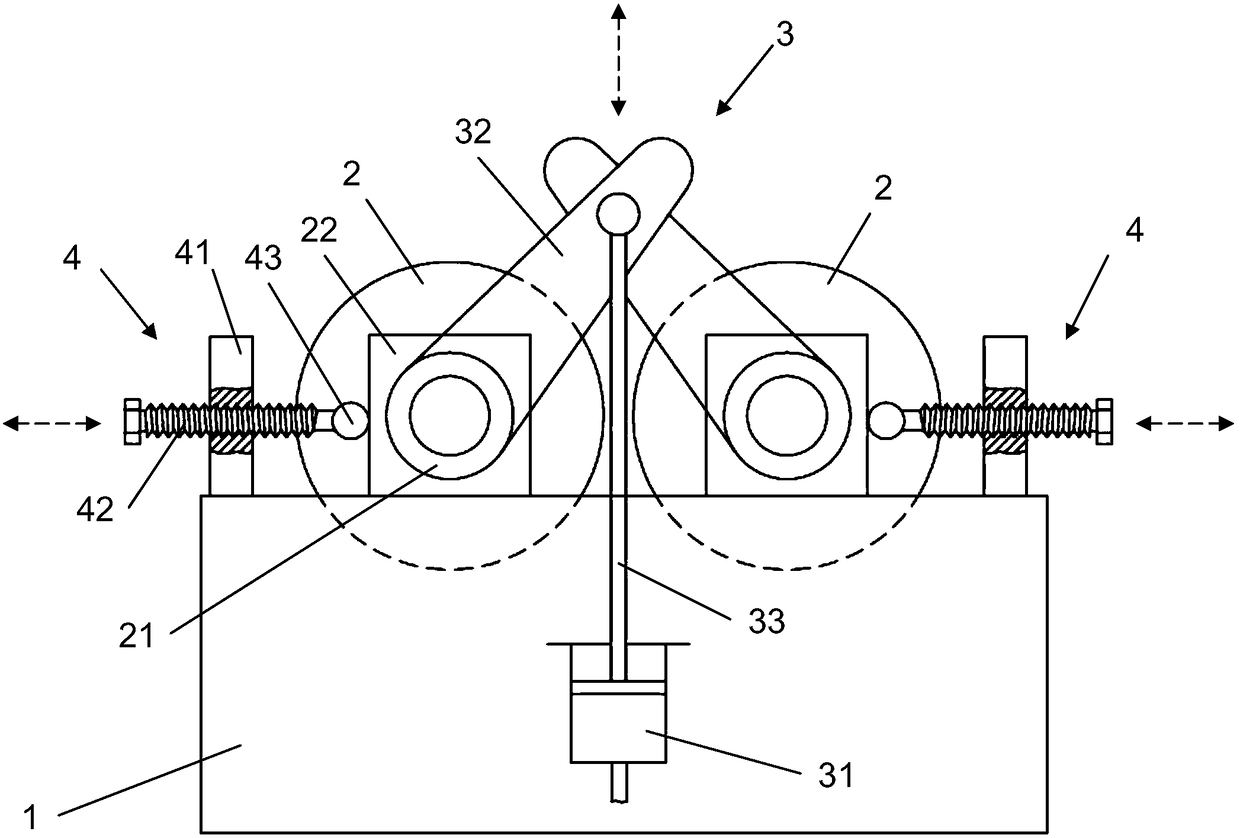

[0014] The technical scheme of the present invention will be further explained below in conjunction with the drawings.

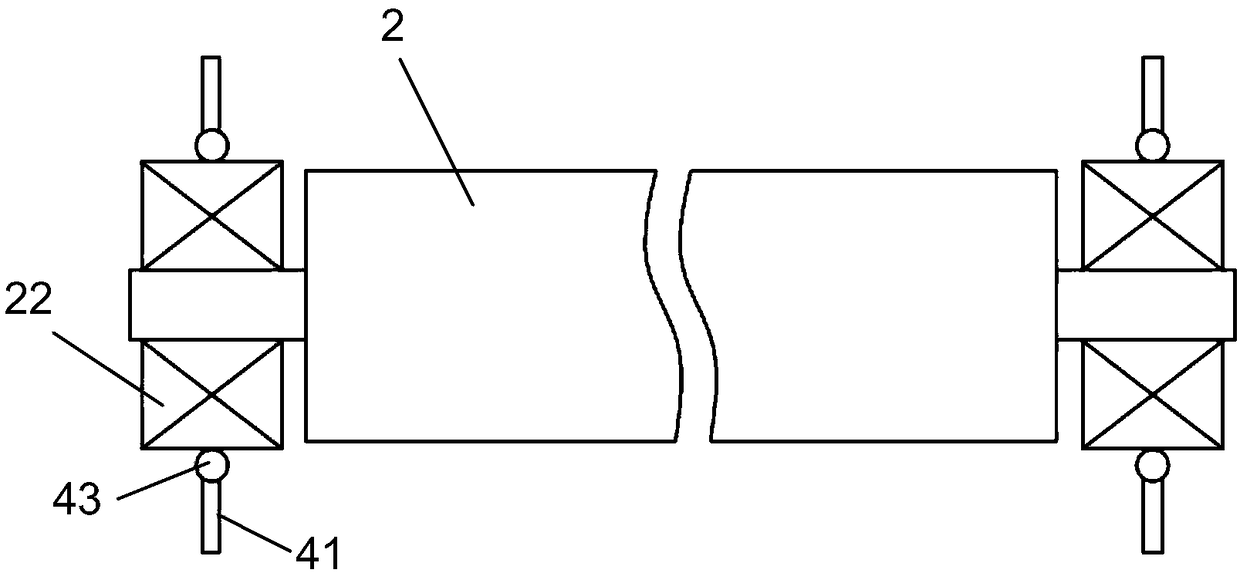

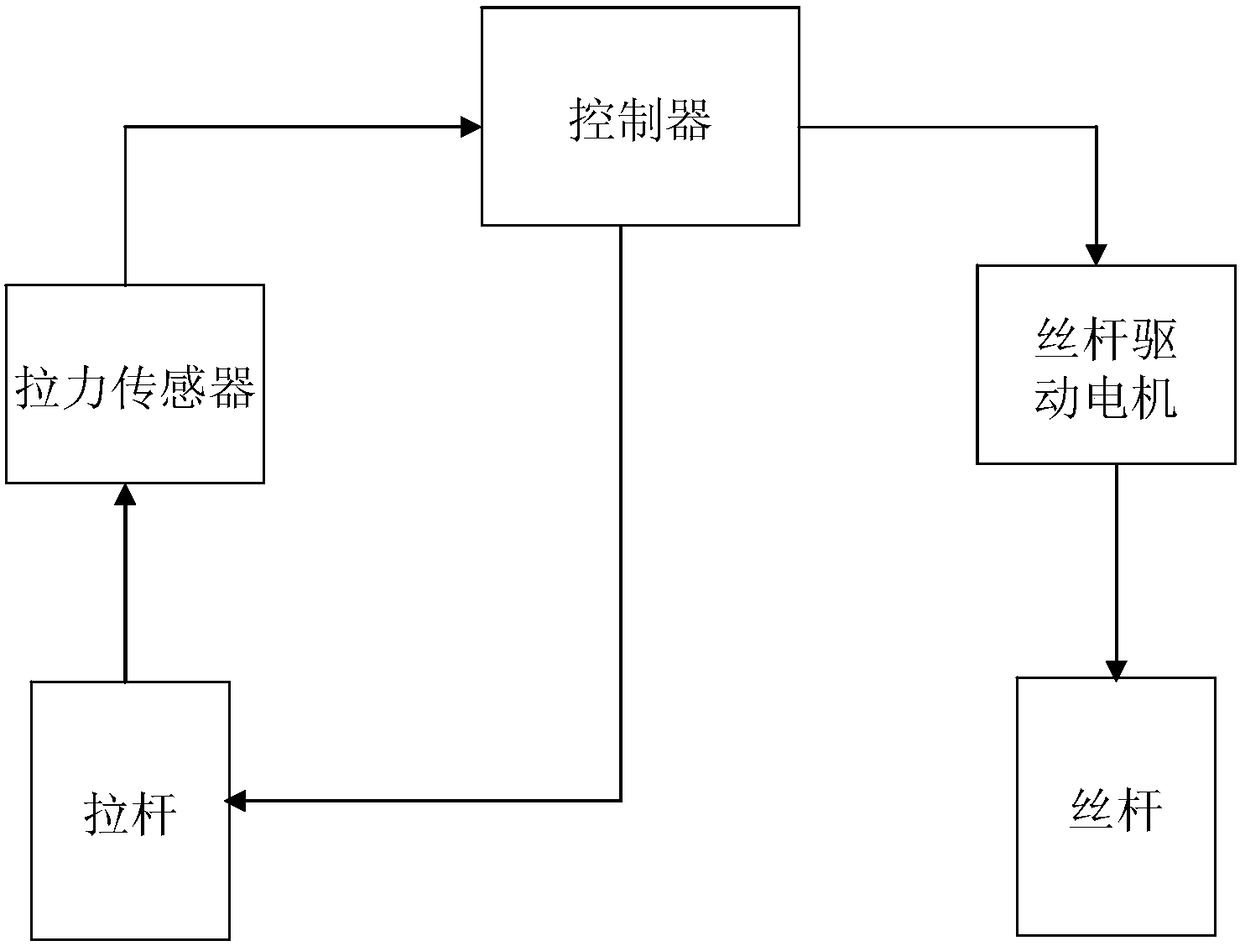

[0015] See Figure 1 ~ Figure 2 As shown, the high-precision anti-bounce two-roll rolling mill of the present invention is the same as the prior art in that it also includes a stand 1, a pair of rolls 2 arranged on the stand 1, and the difference from the prior art is , It also includes an anti-bounce mechanism 3 and a spacing control mechanism 4. The anti-bounce mechanism 3 has two sets, which are respectively arranged at both ends of the roll 2. Each set of anti-bounce mechanism 3 includes a tensioner 31 and a pair of connecting plates 32. The upper ends of the connecting plates 32 are hinged to the ends of the pull rods 33 of the tensioner 31, and the lower ends of the two connecting plates 32 are respectively connected to the shaft heads 21 at the same side of the two rollers 2, and the pull rods 33 of the tensioner 31 can be pulled downwards to feed the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com