Automatic stamping machine

An automatic sealing machine and moving baffle technology, applied in the field of stamping, can solve the problems of low efficiency, inconvenience, reduce the high-speed automation of the stamping machine, etc., and achieve fast and accurate pressing action, convenient connection of the pressing plate, and stamping movement. Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

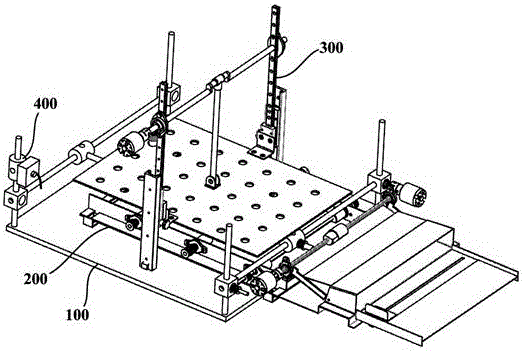

[0050] figure 1 It is a schematic structural diagram of an automatic stamping machine according to an embodiment of the present invention, as figure 1 shown and refer to Figure 2 to Figure 5 , the embodiment of the present invention provides an automatic stamp sealing machine. The automatic stamping machine may include a base 100 , a paper feeding device 200 , a stamping device 300 and an automatic ink supply device 400 .

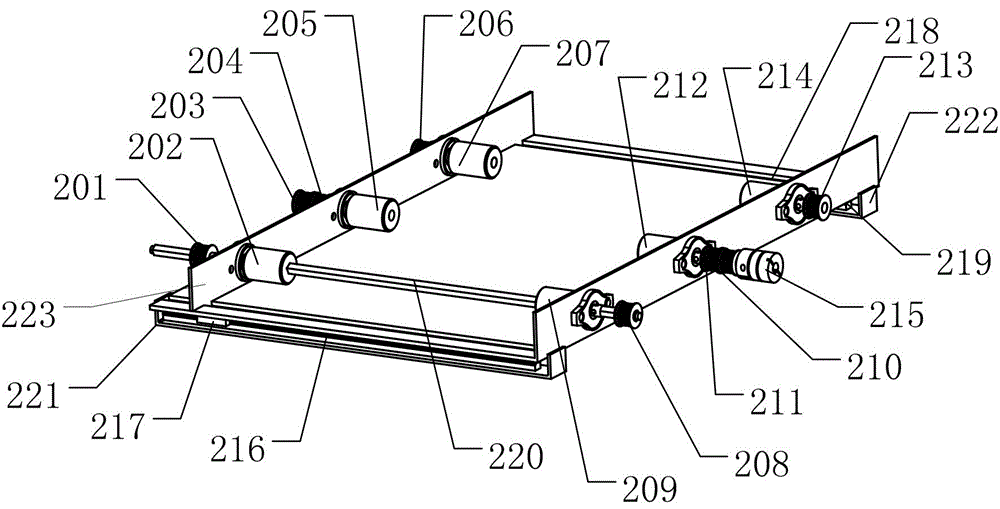

[0051] The paper feeding device 200 is installed on the base 100 and may have: a workbench, and a paper jam module and a paper conveying module installed on the workbench. The jam module is configured to controllably adjust the jam size to hold paper of different sizes. The paper transport module is configured to move the paper in a predetermined direction.

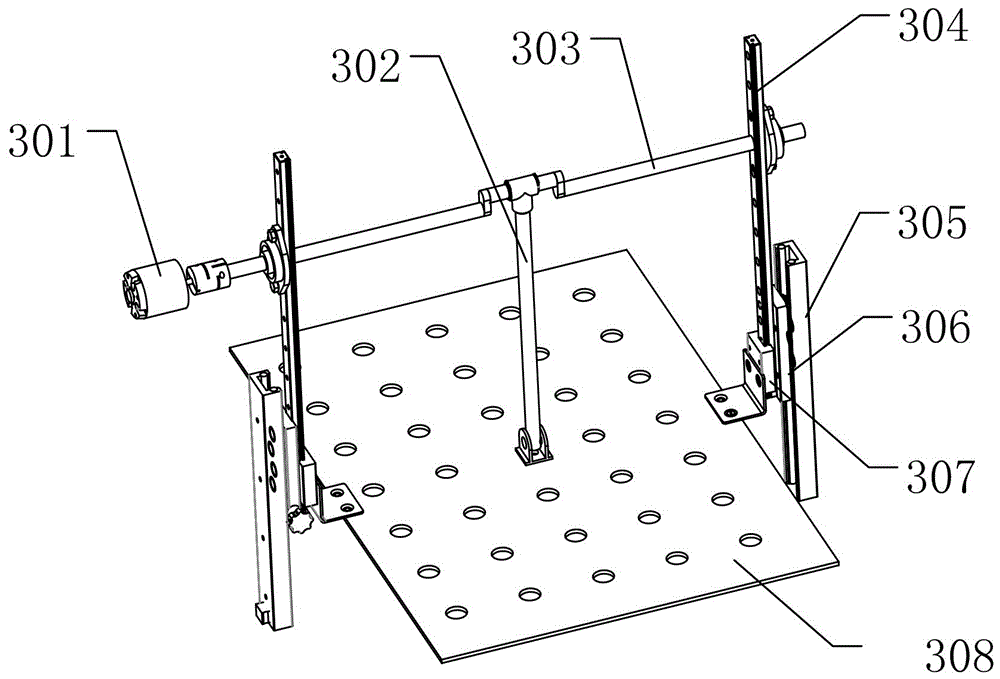

[0052] The stamping device 300 may include: a first bracket installed on the base 100 , and a pressing plate 308 mounted on the first bracket so as to be able to move up and down. The platen 308 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com