Fully automatic ivory fruit processing device for advanced handicraft production

A fully automated, processing device technology, used in metal processing, wood processing appliances, plant material machining, etc., can solve problems such as low product quality and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

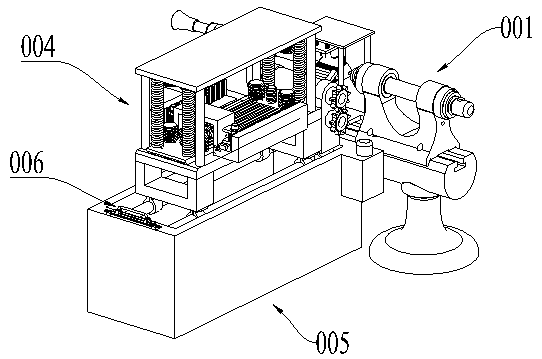

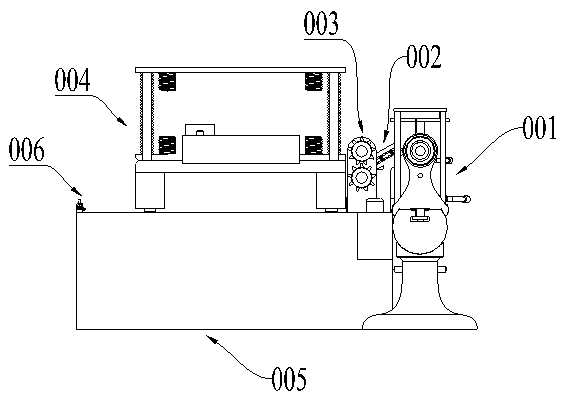

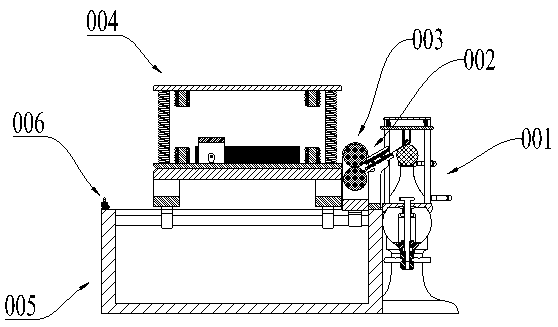

[0048] The present invention will be further described below in conjunction with accompanying drawing.

[0049] Please refer to figure 1 , figure 2 and image 3 , a fully automatic ivory fruit processing device for high-grade handicraft production, characterized in that it includes a peeling device 001, an ironing device 002, a sheet conveying device 003 and a shredding device 004, and the peeling device 001 is used to The object to be peeled is processed into thin slices, the ironing device 002 is arranged in cooperation with the peeling device 001, and is used to iron the slices output by the peeling device 001, and the feed port of the sheet conveying device 003 is connected to the The discharge port of the ironing device 002 is arranged oppositely, the discharge port of the sheet conveying device 003 is provided opposite to the feed port of the shredded device 004, and the shredded device 004 is used for ironing Thin slices are cut into filaments.

[0050] The above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com