Lacquer painting manufacturing engraving cutter with blade convenient to replace

A carving knife and blade technology, applied in the field of carving knives, can solve the problems of not being able to meet the needs of lacquer painting carving, not suitable for long-distance viewing, and a single knife head, etc., and achieve the effects of easy replacement, appropriate proportion, and smooth and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

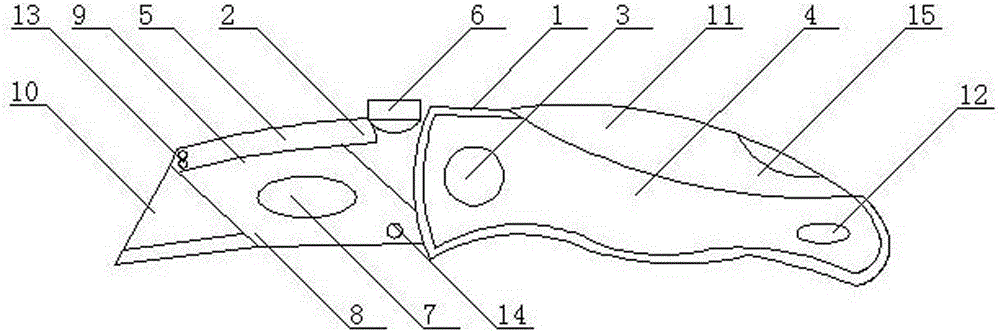

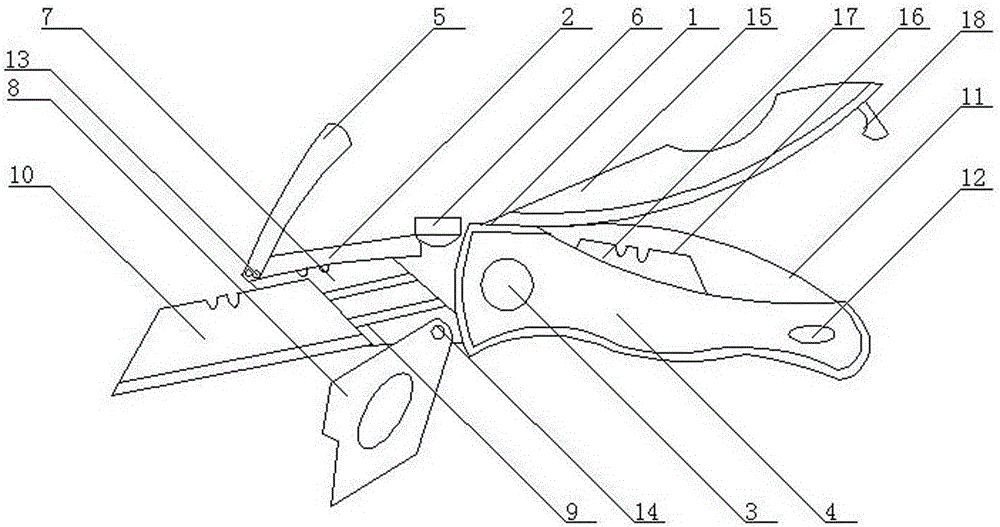

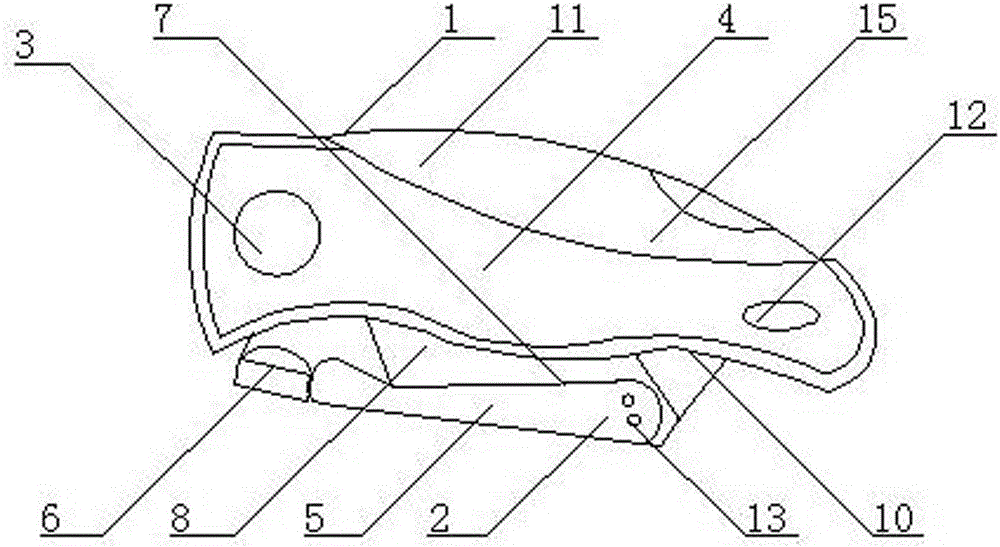

[0020] As shown in the figure, a carving knife for lacquer painting making is easy to replace the blade, including a knife body 1, a knife head 2 is installed on the left side of the knife body 1, and a knife handle 4 is connected to the right side of the knife head 2 through a rotating shaft 2 , the cutter head 2 can be snapped back to the inside of the lower end of the handle 4 by flipping 90 degrees to the right and down.

Embodiment 2

[0022] As shown in the figure, the top left side of the cutter head 2 is equipped with a fixed top cover 5, the top right side of the cutter head 2 is equipped with a force application button 6, the middle end of the cutter head 2 is equipped with a blade fixing area 7, and the fixed top The bottom end of the cover 5 is connected to the upper end of the blade fixing area 7, the front of the blade fixing area 7 is equipped with a fixed blade body 8, the middle end of the blade fixing area 7 is equipped with a blade placement area 9, and the blade placement area 9 is equipped with a blade 10.

Embodiment 3

[0024] As shown in the figure, a blade storage box 11 is installed at the upper end of the knife handle 4 , a cutter head storage area is installed inside the lower end of the knife handle 4 , and a blade storage box switch 12 is installed at the lower end of the front right side of the knife handle 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com