Multi-purpose assembling platform for building ship

An assembly platform, multi-purpose technology, applied in ship construction, ship parts, ship design, etc., can solve the problems of consuming a lot of manpower and material resources, occupying a large space and area, and using a large amount of tire frame materials, and achieving a variety of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. The tire frame template can be installed and removed at will

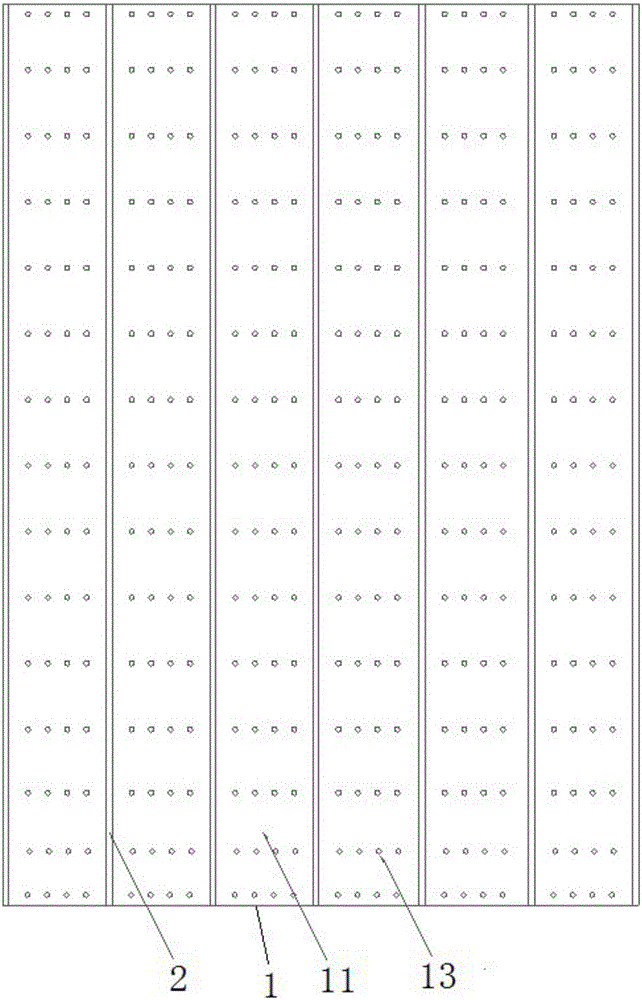

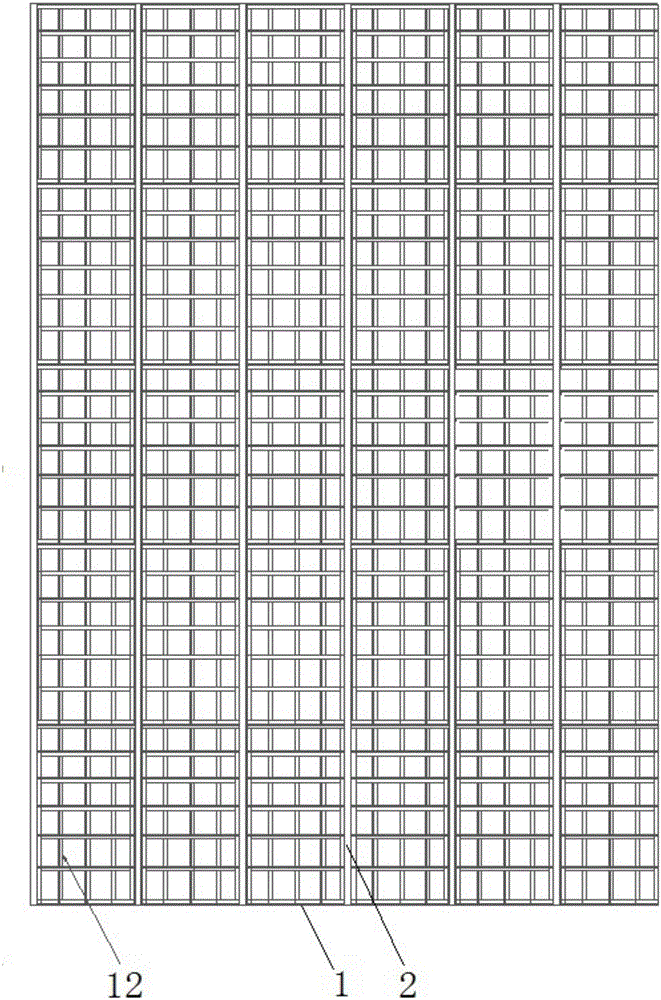

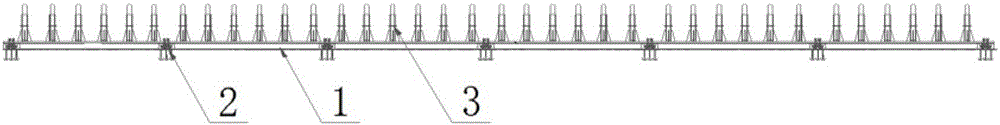

[0019] Such as Figure 1 to Figure 4 As shown, a preferred embodiment of the present invention is an assembly platform for multi-purpose shipbuilding, which includes a plurality of platform units 1 equidistantly arranged along the width direction of the workshop and extending along the length direction of the workshop, and the platform unit 1 consists of a platform The board 11 and the bottom frame 12 are formed, and the two sides of the width of each platform unit 1 are laid with slide rails 2 for installing the hull segment frame 3, and the platform board 11 is provided with a plurality of installation holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com